Foundation shock eliminator

a technology of foundation shock and eliminator, which is applied in the direction of building components, building types, constructions, etc., can solve the problems of adverse effects of shocks on the fabrication of electronic products, buildings collapsing or the influence of machines, and conventional foundation shock eliminators cannot diminish the effect of shocks transmitted through the ground, so as to reduce the effect of shock and efficiently dissipate shock energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

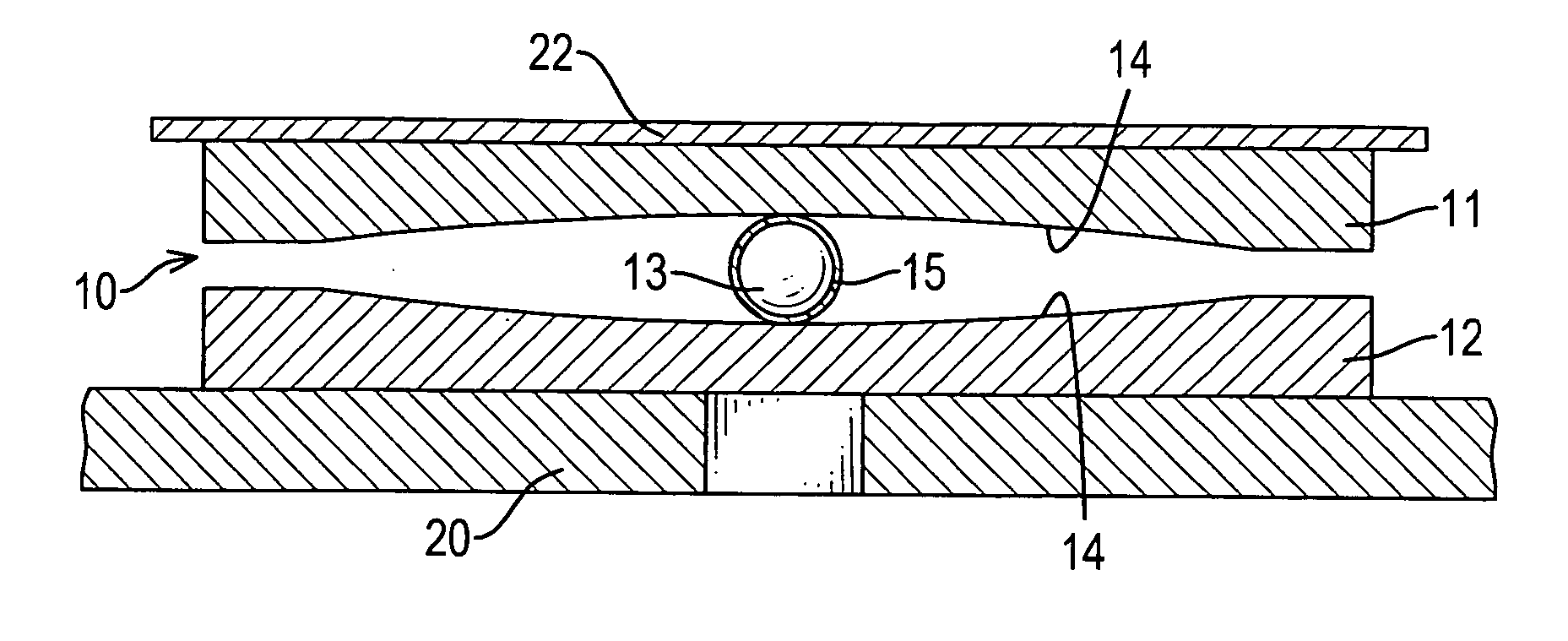

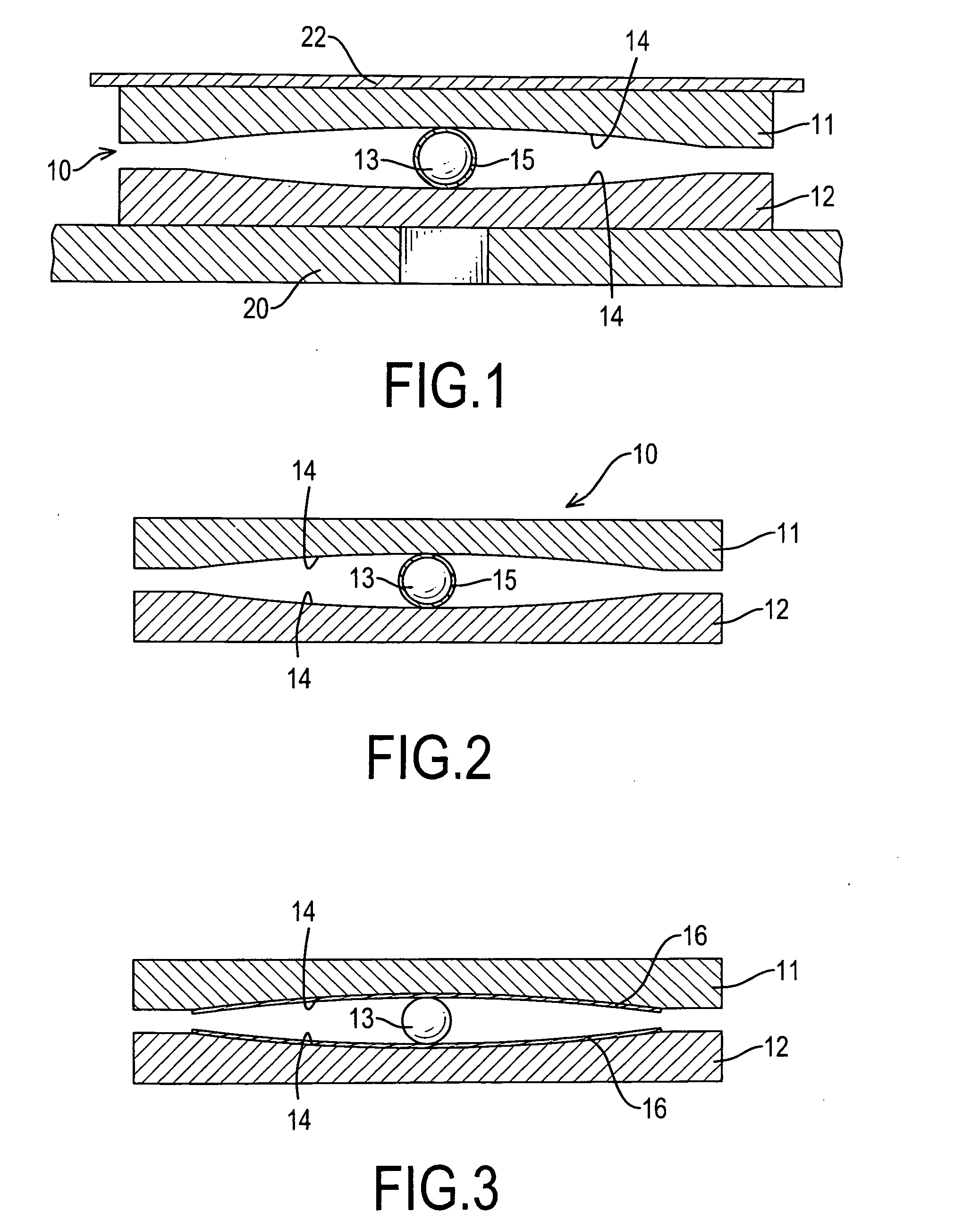

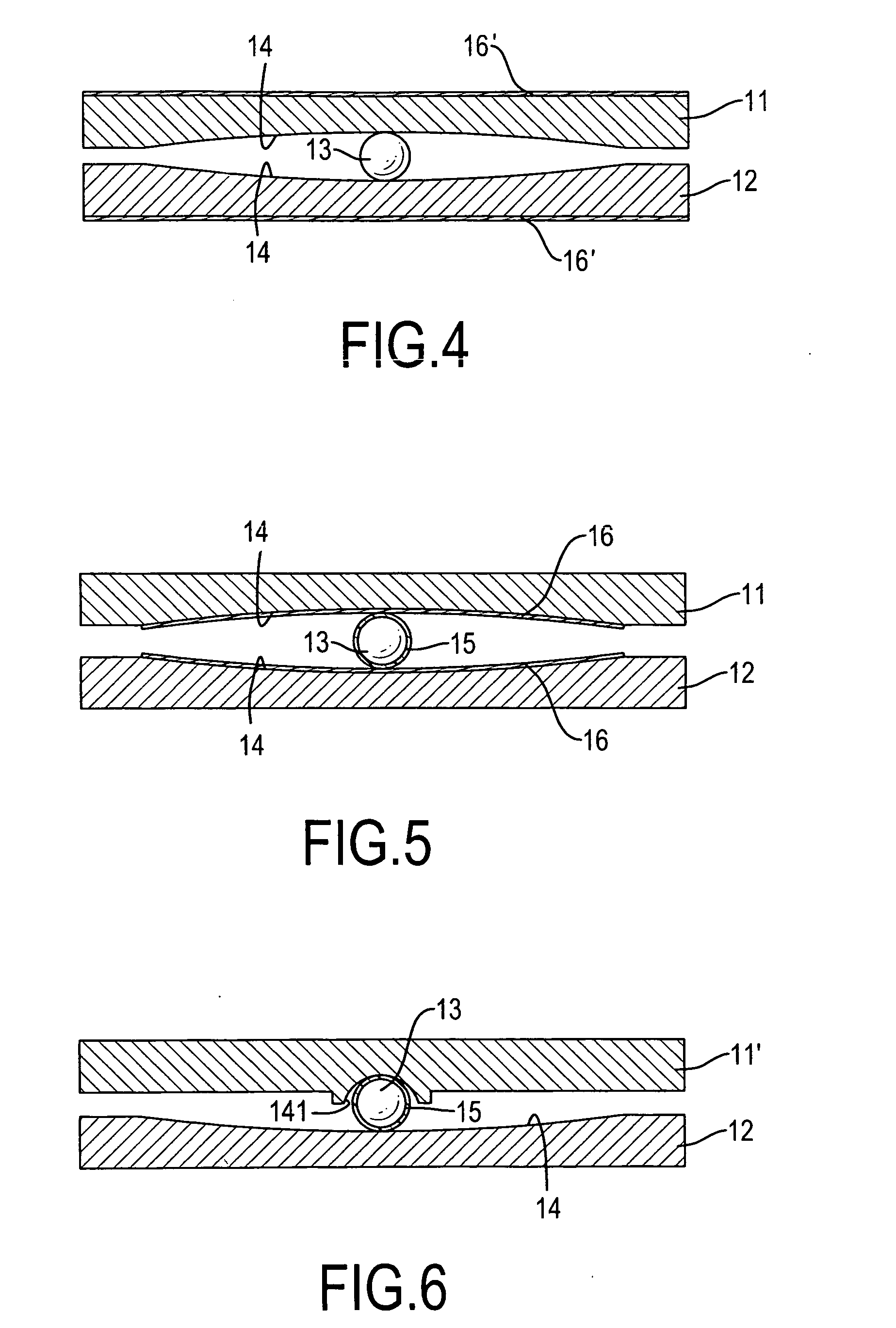

[0036] the energy damping coating can be viscoelastic material, rubber or other resilient material and is implemented as a roller coating (15). The roller coating (15) completely covers the roller (13). The roller coating (15) increases the damping of the entire foundation shock eliminator (10), which dissipates more shock energy than a conventional foundation shock eliminator.

second embodiment

[0037] With further reference to FIG. 3, the energy damping coating in accordance with the present invention is implemented as two surface coatings (16). The surface coatings (16) respectively cover the concave inner surfaces (14) of the upper block (11) and the lower stationary base (12). The roller (13) is movably mounted between the surface coatings (16).

[0038] With further reference to FIG. 4, a third embodiment of the energy damping coating in accordance with the present invention repositions the surface coatings (16) of the second embodiment of the energy damping coating to the outer surfaces respectively of the upper block (11) and the lower stationary base (12).

[0039] With further reference to FIG. 5, a fourth embodiment of the energy damping coating is a combination of the roller coating (15) in the first embodiment and the surface coatings (16) of the second embodiment of the energy damping coating. The roller coating (15) completely covers the roller (13). The surface co...

third embodiment

[0045] With further reference to FIGS. 11 and 12, a foundation shock eliminator in accordance with the present invention comprises a modified upper block (11″), a modified lower stationary base (12′), a roller (13), an energy damping coating and multiple restitution elements (17). The modified upper block (11″) has a hemispheric concave inner surface (141). The modified lower stationary base (12′) has a top surface (not numbered) and an upper wall (121). The upper wall (121) protrudes from the top surface and encloses an area (not numbered). The enclosed area has a central position (not numbered). The modified upper block (11″) is mounted movably inside the upper wall (121). The hemispheric concave inner surface (141) faces the modified lower stationary base (12′). The roller (13) is a ball or a cylindrical rod, is mounted rotatably in the hemispheric concave inner surface (141) and moves inside the enclosed area on the modified lower stationary base (12′). The energy damping coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com