Selector weight plate

a technology of selector and weight plate, which is applied in the direction of weights, gymnastic exercise, sport apparatus, etc., can solve the problems of plate deterioration, plate rust, plate squeezing, etc., to prevent plate squeezing, prevent plate deterioration, and prevent loud noises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

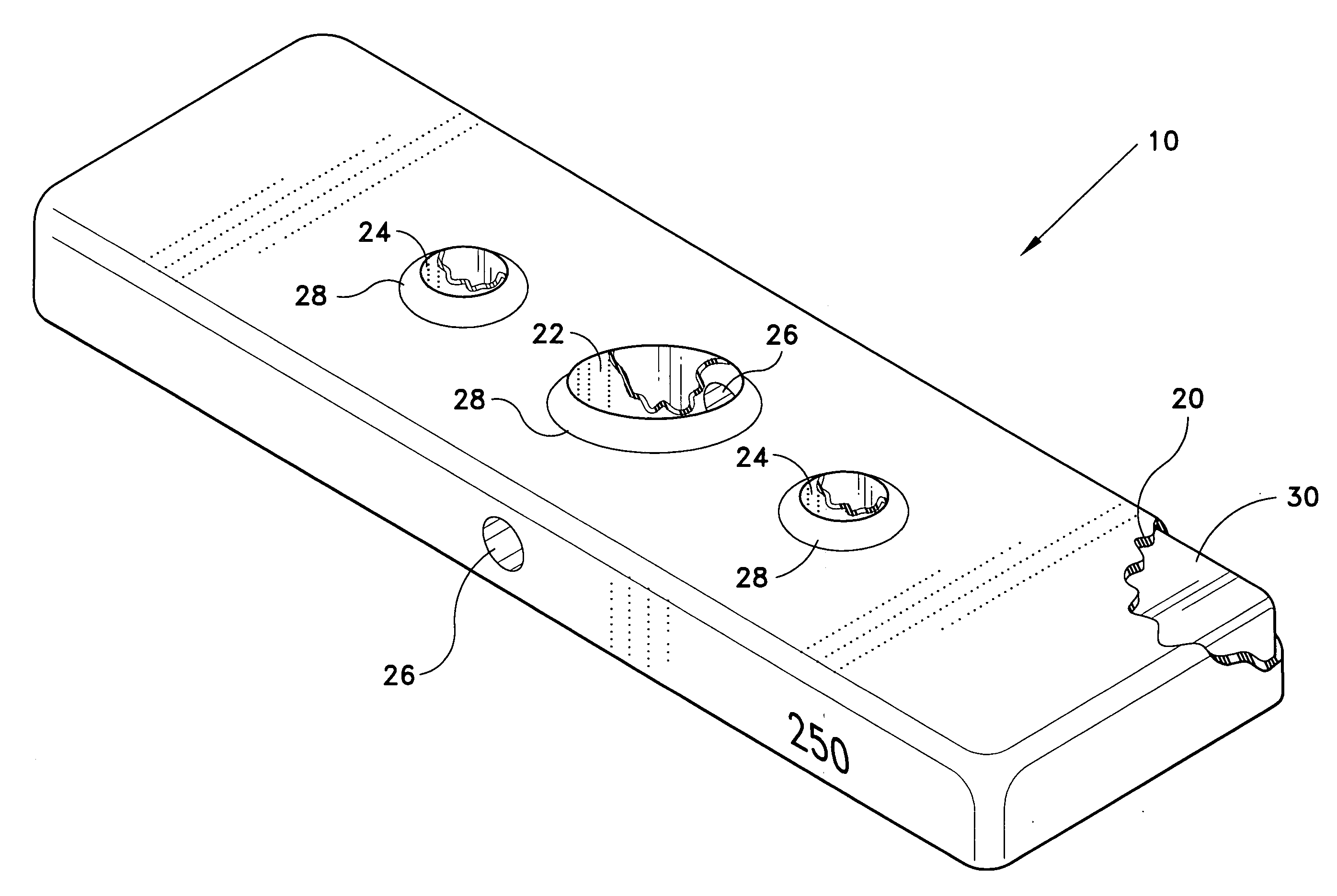

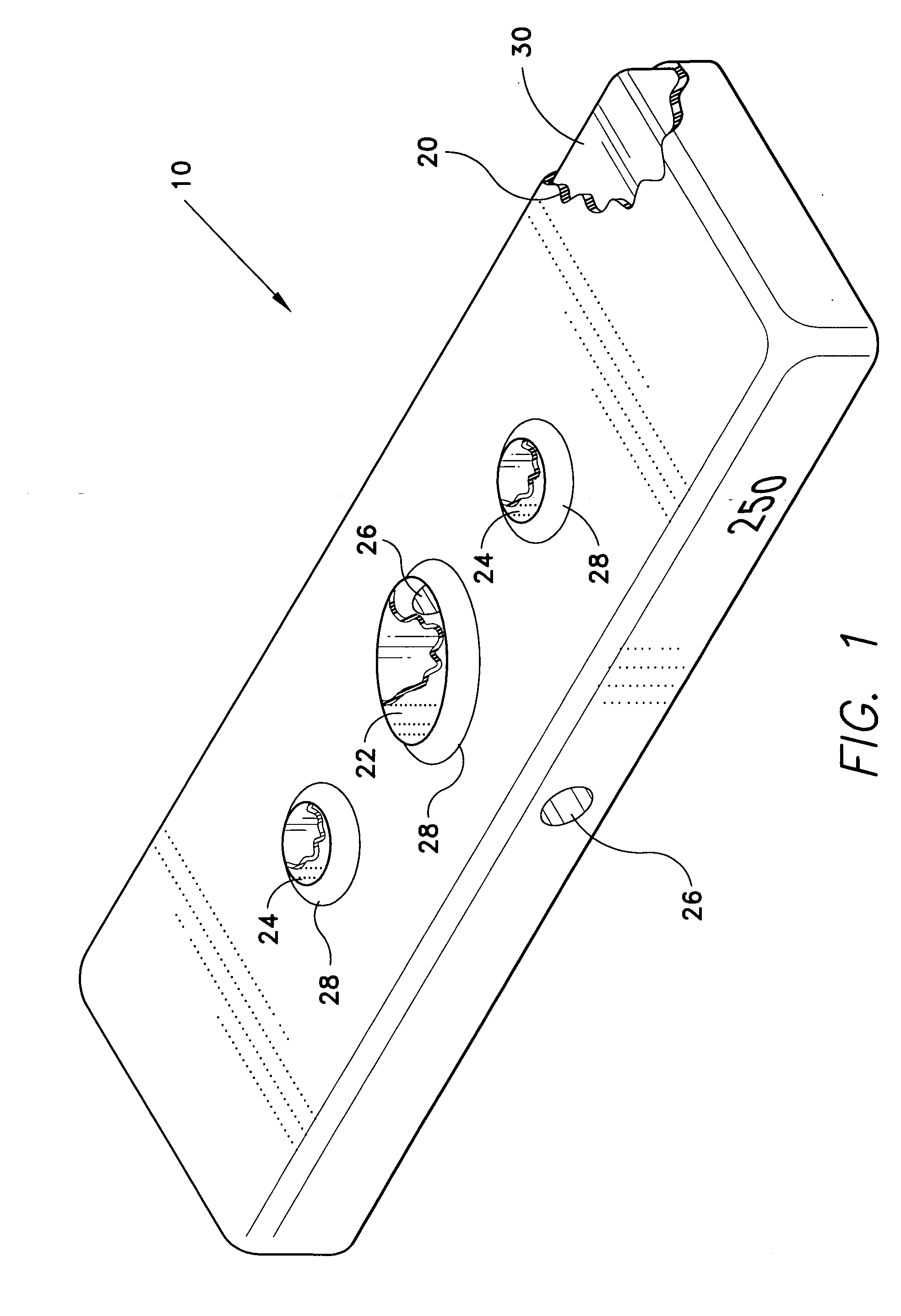

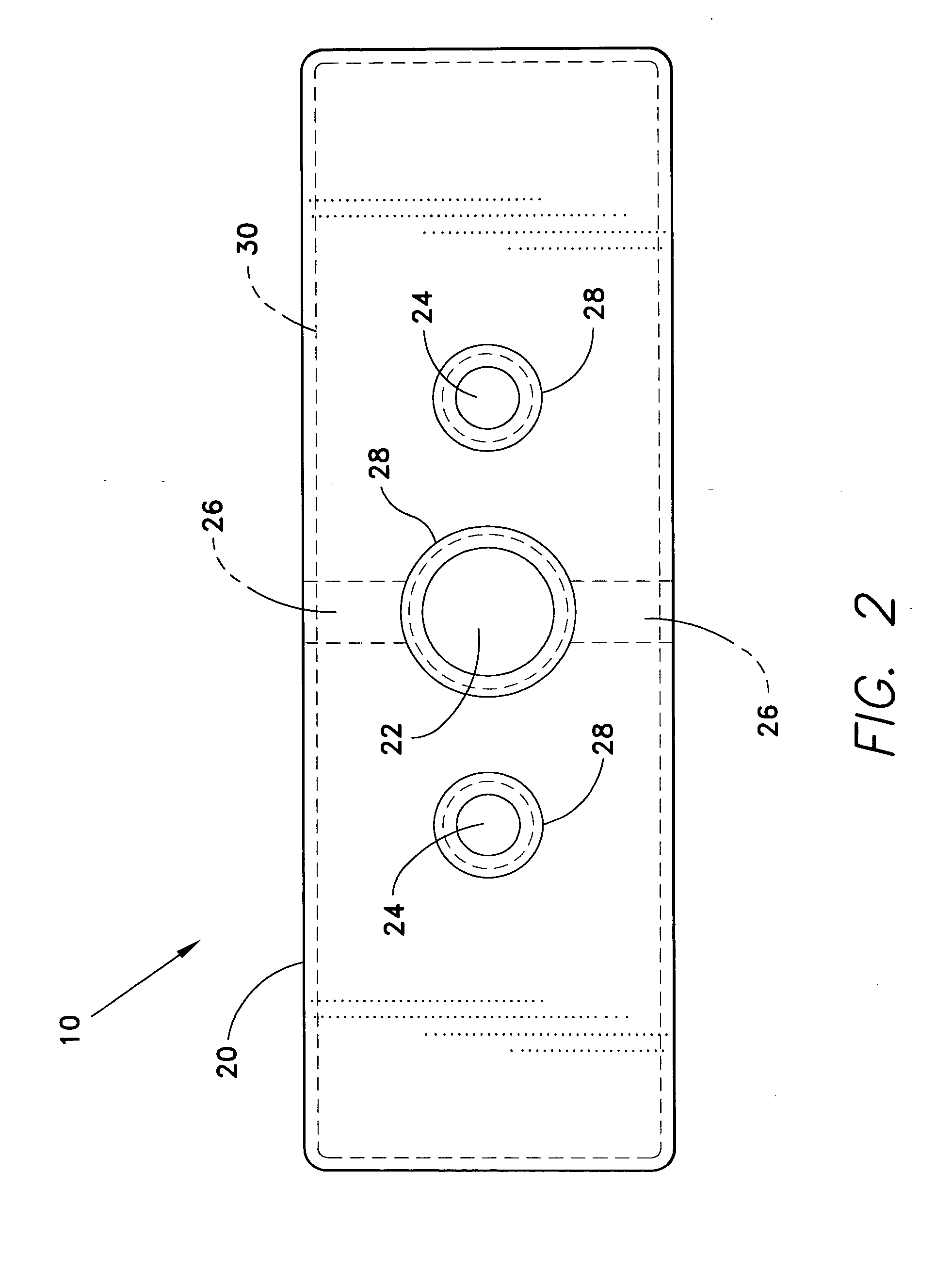

[0019] The present invention is a selector weight plate for use with a selector weightlifting machine, designated generally as 10 in the drawings.

[0020] Referring to FIGS. 1-3 of the drawings, selector weight plate 10 includes weight member 30 encased by cover 20. Selector weight plate 10 is provided with a central vertical aperture 22 therethrough. Central vertical aperture 22 is provided for receiving the center, weight plate holding post found on standard selector weightlifting machines. Selector weight plate 10 is also provided with a pair of offset vertical apertures 24 therethrough. Offset vertical apertures 24 are equally spaced from center vertical aperture 22 and are provided to receive the guide rails found on a standard selector weightlifting machines for helping to provide linear vertical movement of the selector weight plates 10 during an exercise routine.

[0021] Selector weight plate 10 is further provided with a pair of horizontal apertures 26 with each aperture 26 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com