Roof membrane fastener, system, and fastening method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

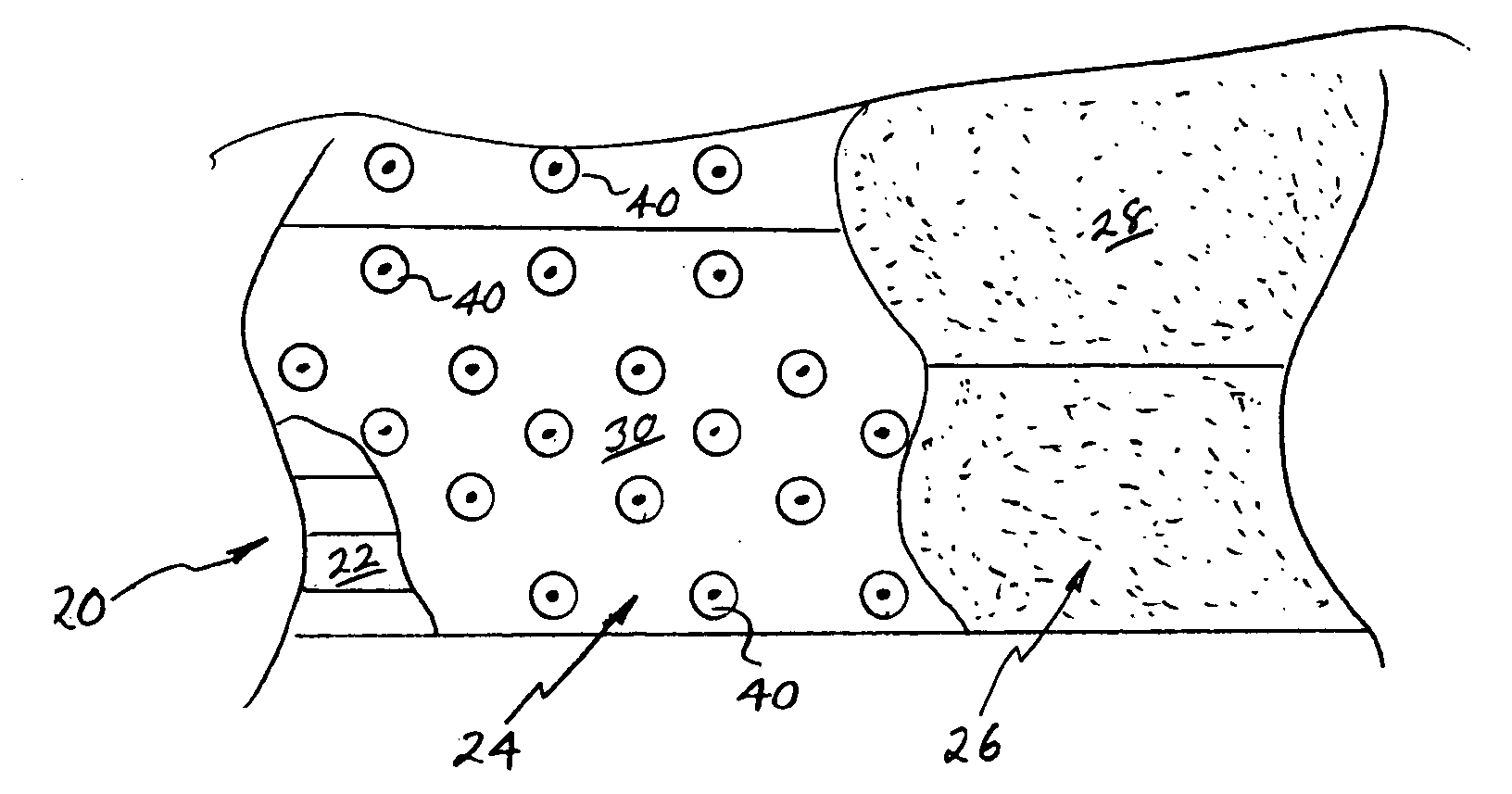

[0018]FIG. 1 shows a partial plan view of an example of a multi-layer roof sheet membrane system of the subject invention 20 installed on a roof substrate 22 with portions of the multi-layer roof sheet membrane system 20 broken away to better show underlying layers of the system. The multi-layer roof sheet membrane system 20 includes a base sheet membrane 24 and a cap sheet membrane 26 with a mineral surfaced topside major surface 28 that is bonded to the base sheet membrane 24 by the asphalt coated self-adhering topside major surface 30 of the base sheet membrane. The base sheet membrane 24 may be a self-adhering topside and bottom side base sheet membrane that preferably has a sheet, sand, or granular layer interposed between the bottom side major surface of the membrane and the roofing substrate 22 to keep the base sheet membrane from adhering to the roofing substrate or the base sheet membrane 24 may be a base sheet membrane with a self-adhering topside major surface and a non-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com