Carrying handle of luggage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

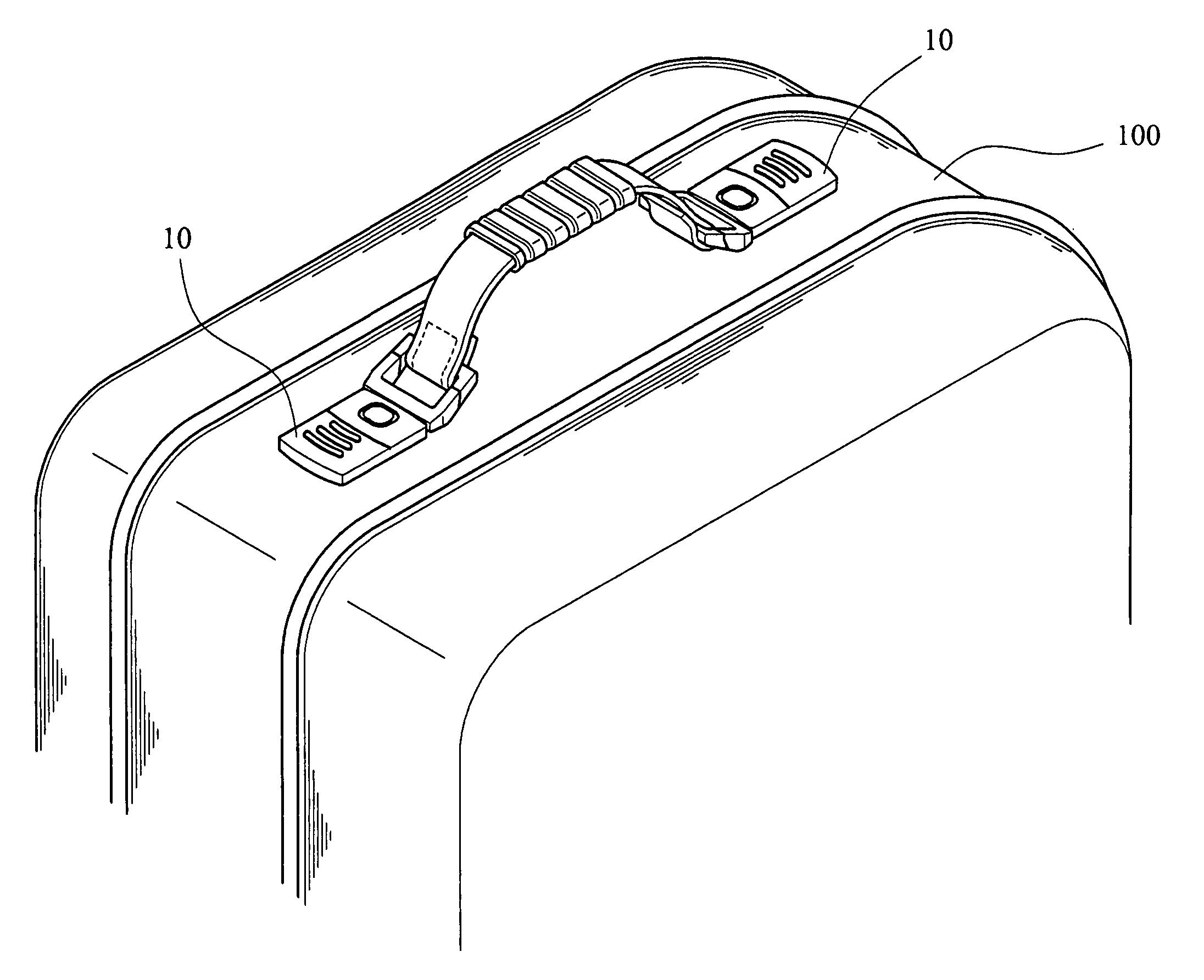

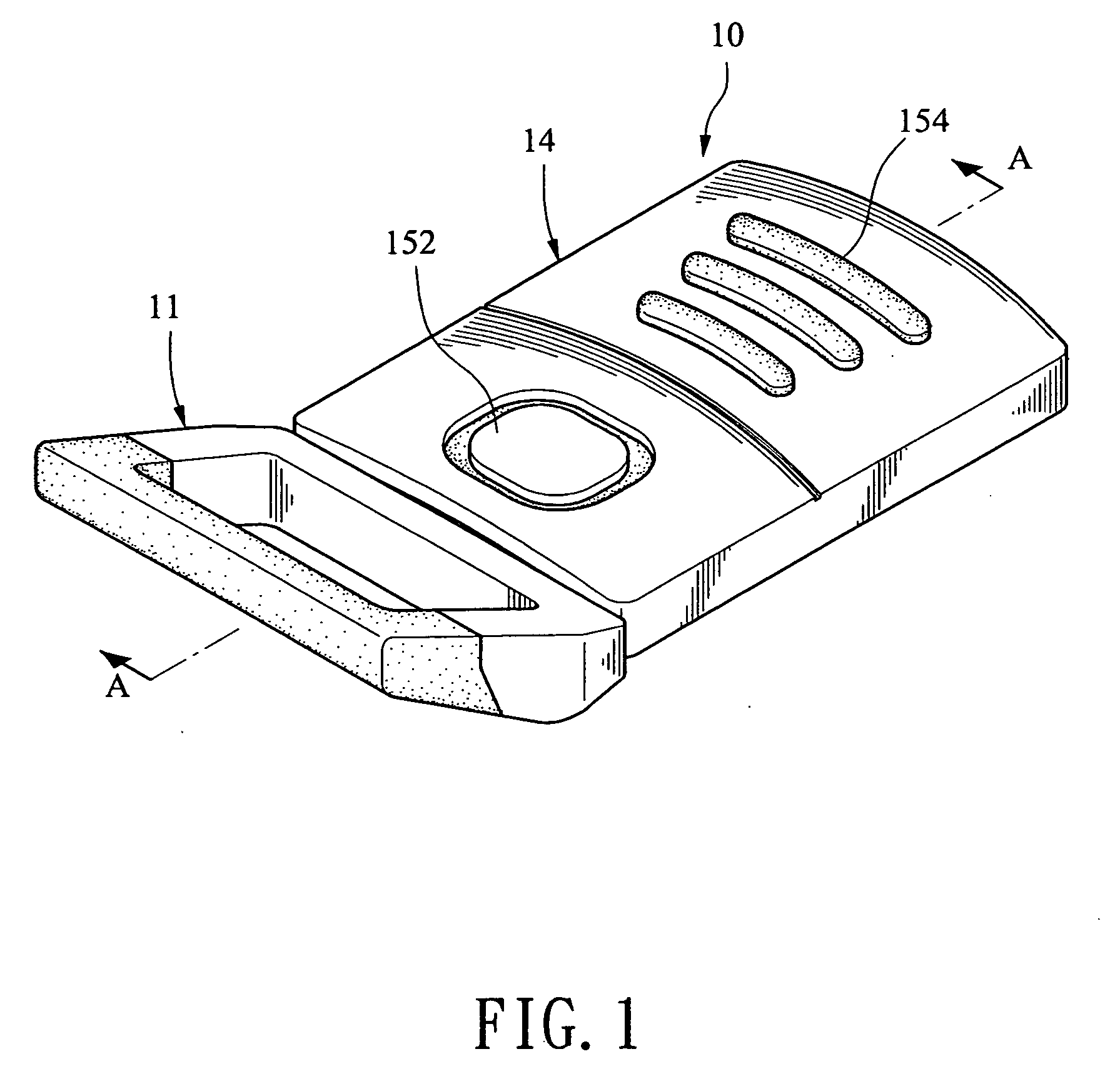

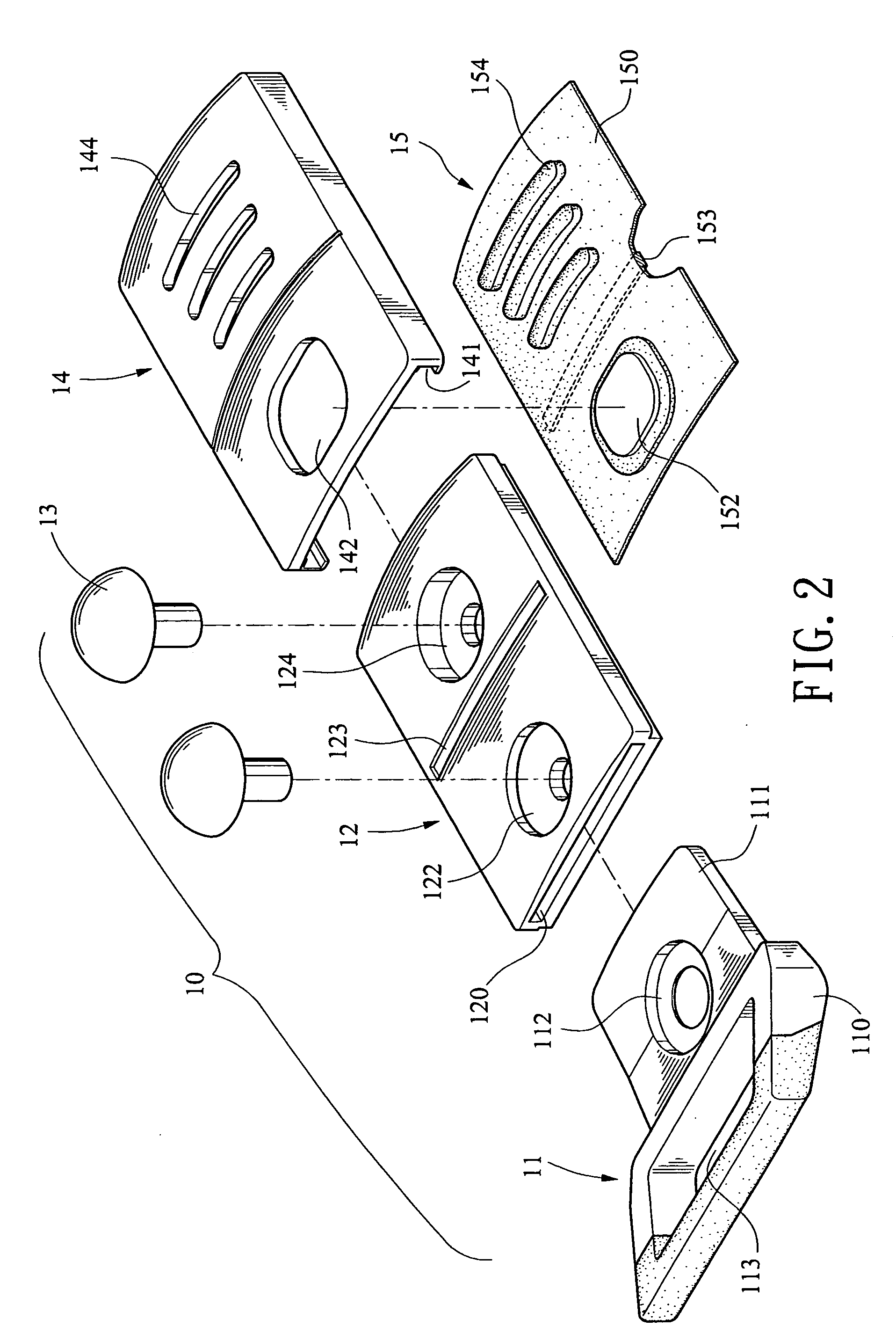

[0019] Referring to FIGS. 1 to 5, there is shown a carrying handle having two end units 10 mounted on a top of luggage 100 in accordance with the invention. Either end unit 10 comprises a joining member 11, a body 12, a cover 14, and an abutment plate 15. Each component will be described in detail below.

[0020] The joining member 11 is formed of metal (e.g., zinc alloy, copper and aluminium alloy, or the like) and comprises an upwardly inclined loop 110 for enclosing a rectangular opening 113 with strap looped around, and a horizontal section 111 having a staged hole 112. The rectangular, flat body 12 has a section of substantial “T” and is formed of plastic material. The body 12 comprises a slot 120 at one end for receiving the horizontal section 111, a first staged hole 122 penetrated the slot 120, the hole 122 being aligned with the hole 112 so that a rivet 13 is able to drive through both the holes 122 and 112 into the luggage 100 for fastening, a widthwise groove 123 in about c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com