Apparatus for securing gasket prior to lid installation

a technology for securing gaskets and lids, applied in the field of plastic containers, can solve problems such as lack of means, and achieve the effect of improving manner and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

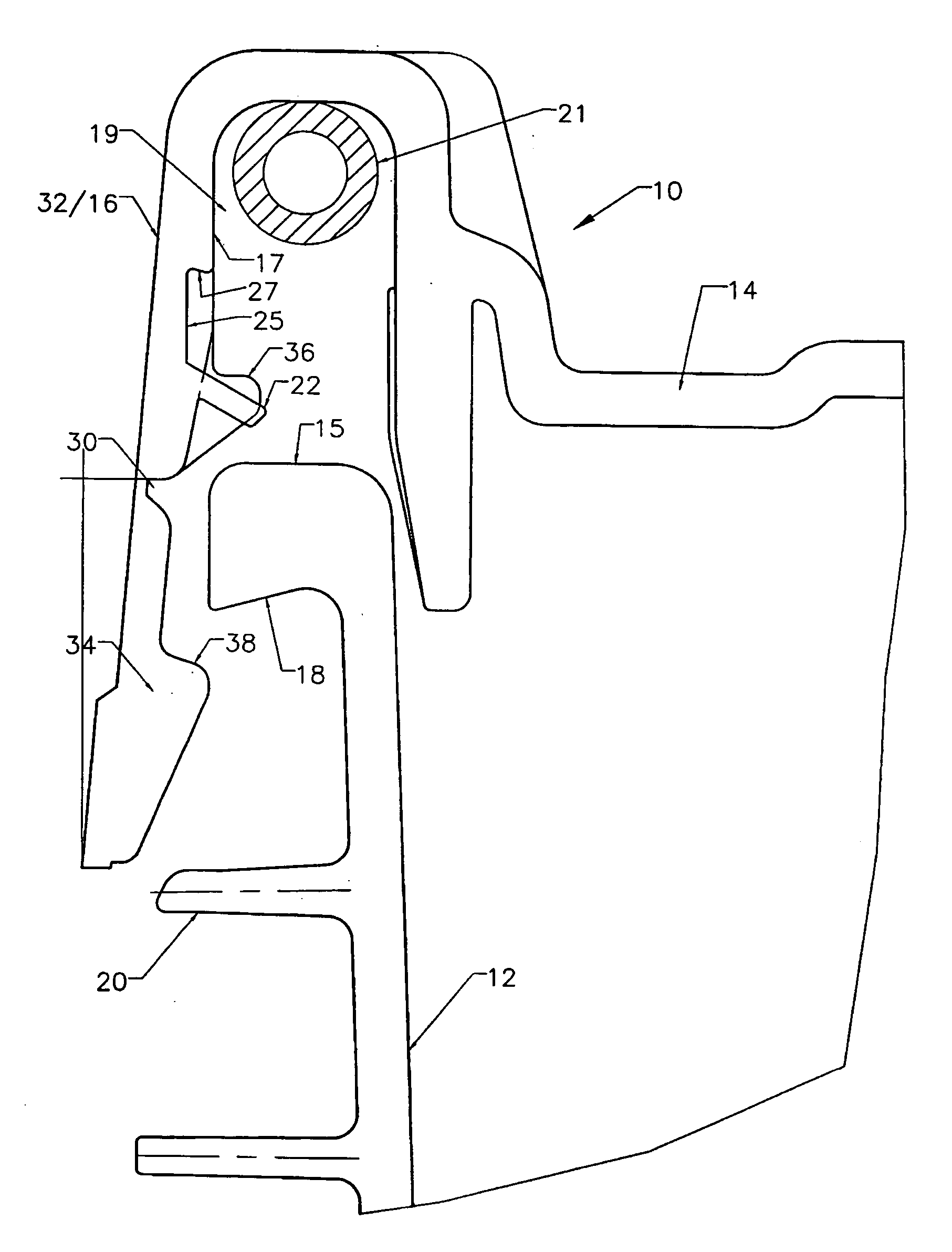

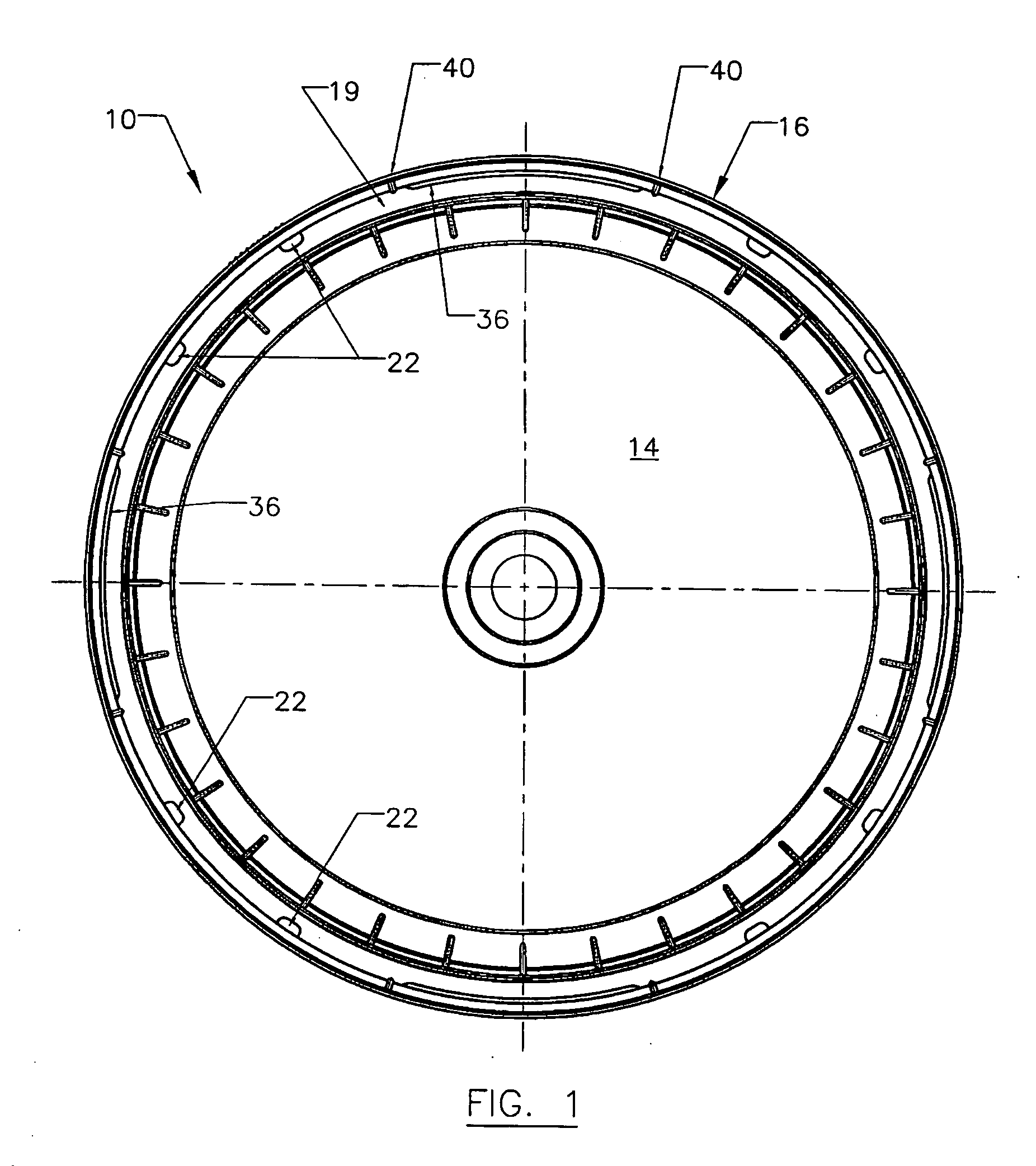

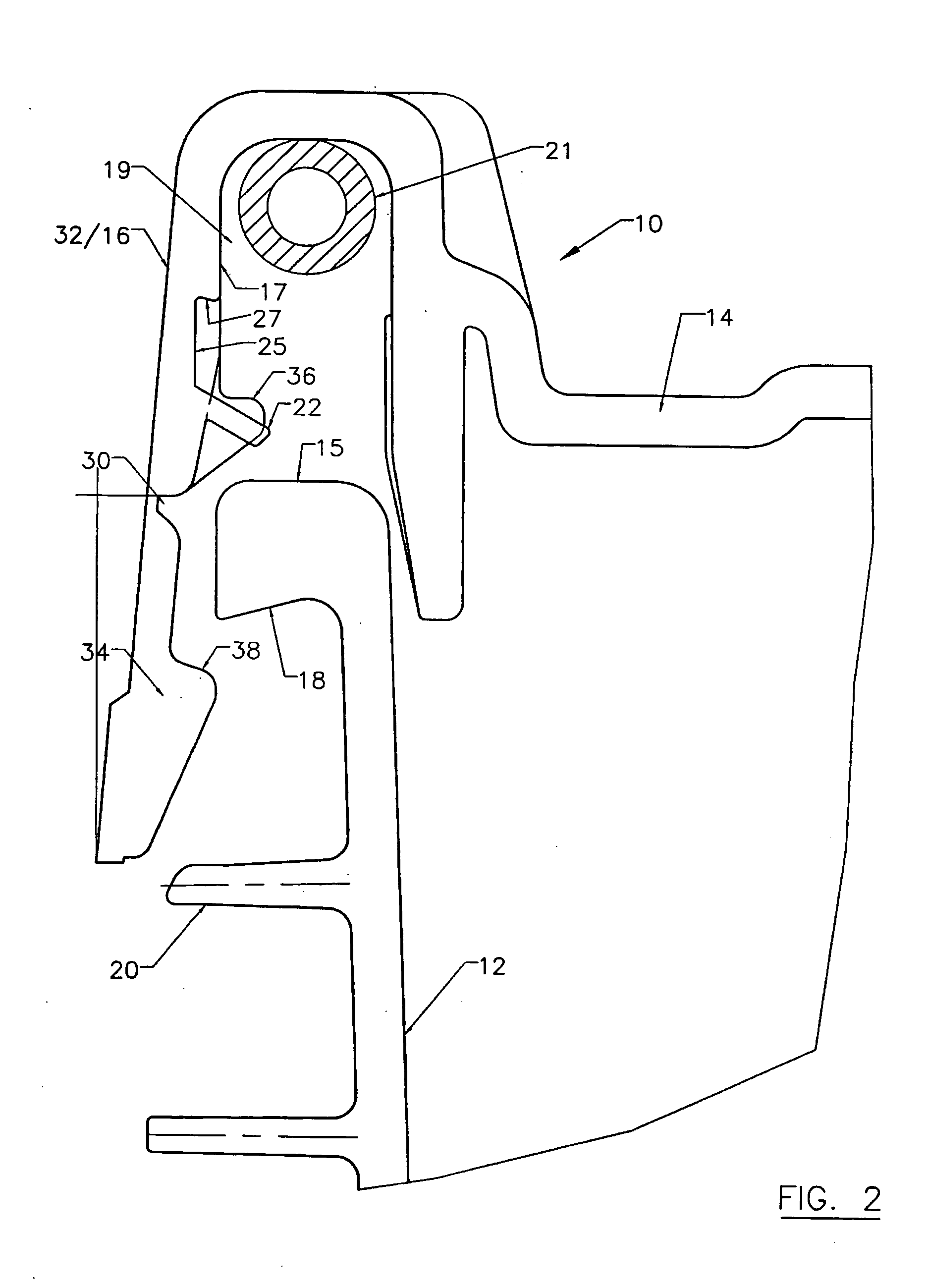

[0018] In an example embodiment a plastic container lid (10) is disclosed for a container (12), the container having an upper peripheral rim portion (15) and upper and lower locking flanges (18, 20) around its upper peripheral rim portion for locking engagement with the lid. The lid has a central portion (14) and a peripheral skirt portion (16) which forms downwardly disposed peripheral channel (19) which is adapted to overlie the container upper rim portion (15) and to hold a sealing gasket (21) therein at an upper portion of said channel at a position above said upper rim portion. The skirt portion forms a plurality of bendable flaps (22) extending within said channel, each of which being movable from a first position (best shown in FIGS. 2 and 3) wherein each said flap extends across a portion of said channel preventing the gasket from falling out of the channel to a second position (best shown in FIGS. 5, 6 and 7) wherein each said flap (22) is positioned within a relief pocket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com