Robotic vision system to locate Z-forms

a robot vision and positioning technology, applied in the field of positioning systems, can solve the problems of saving time and money in the manufacturing of composite structures, and achieve the effect of saving time and money and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

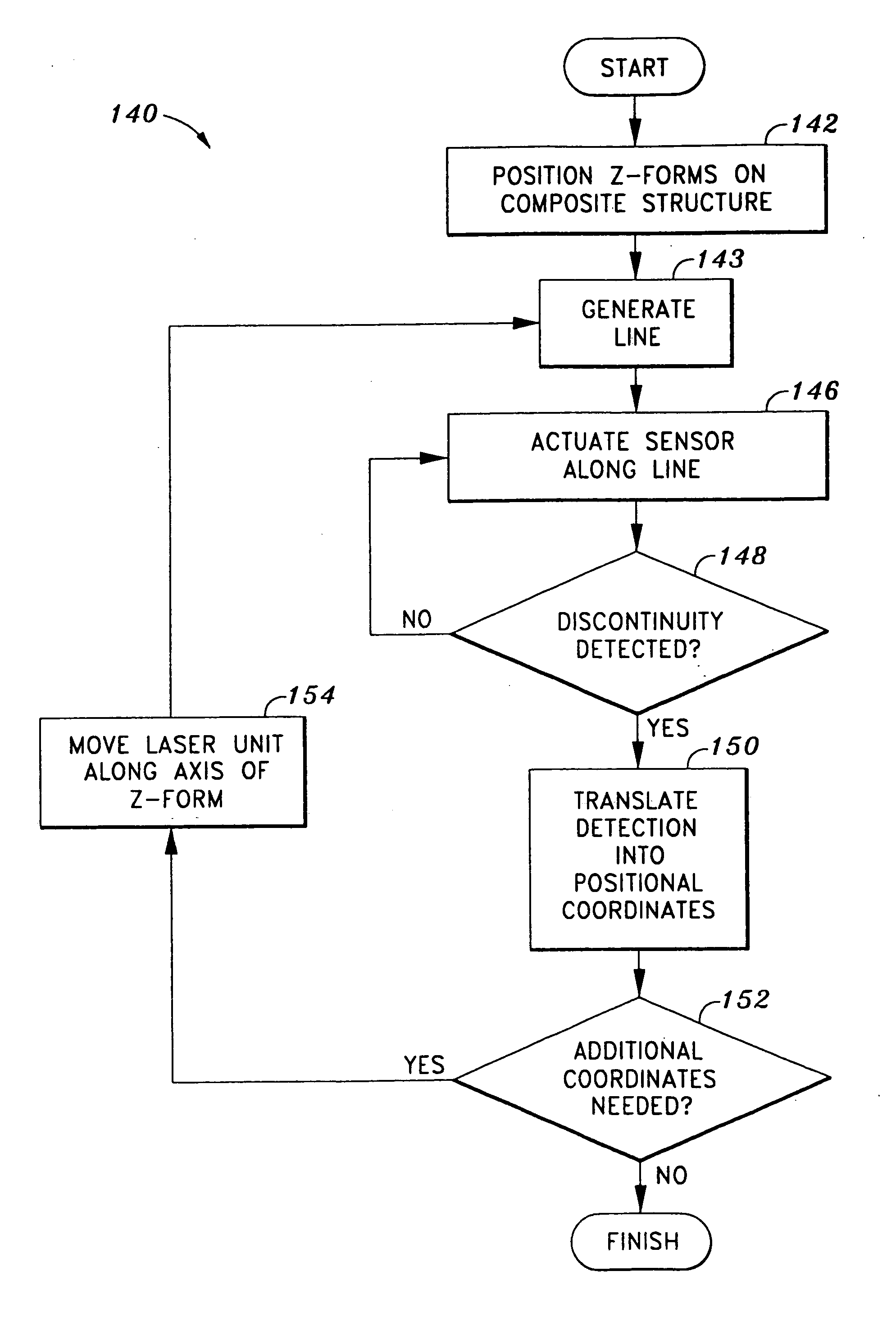

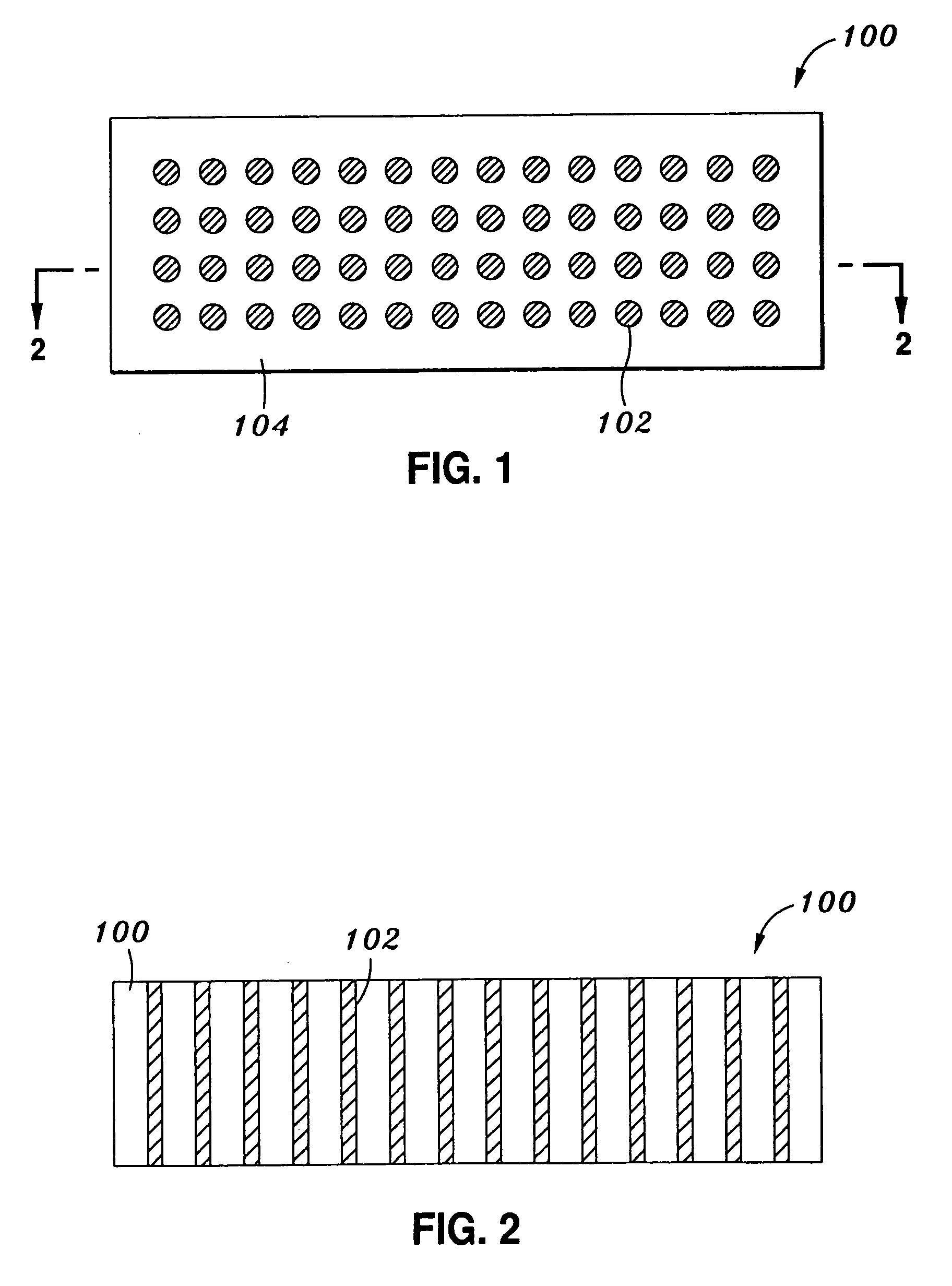

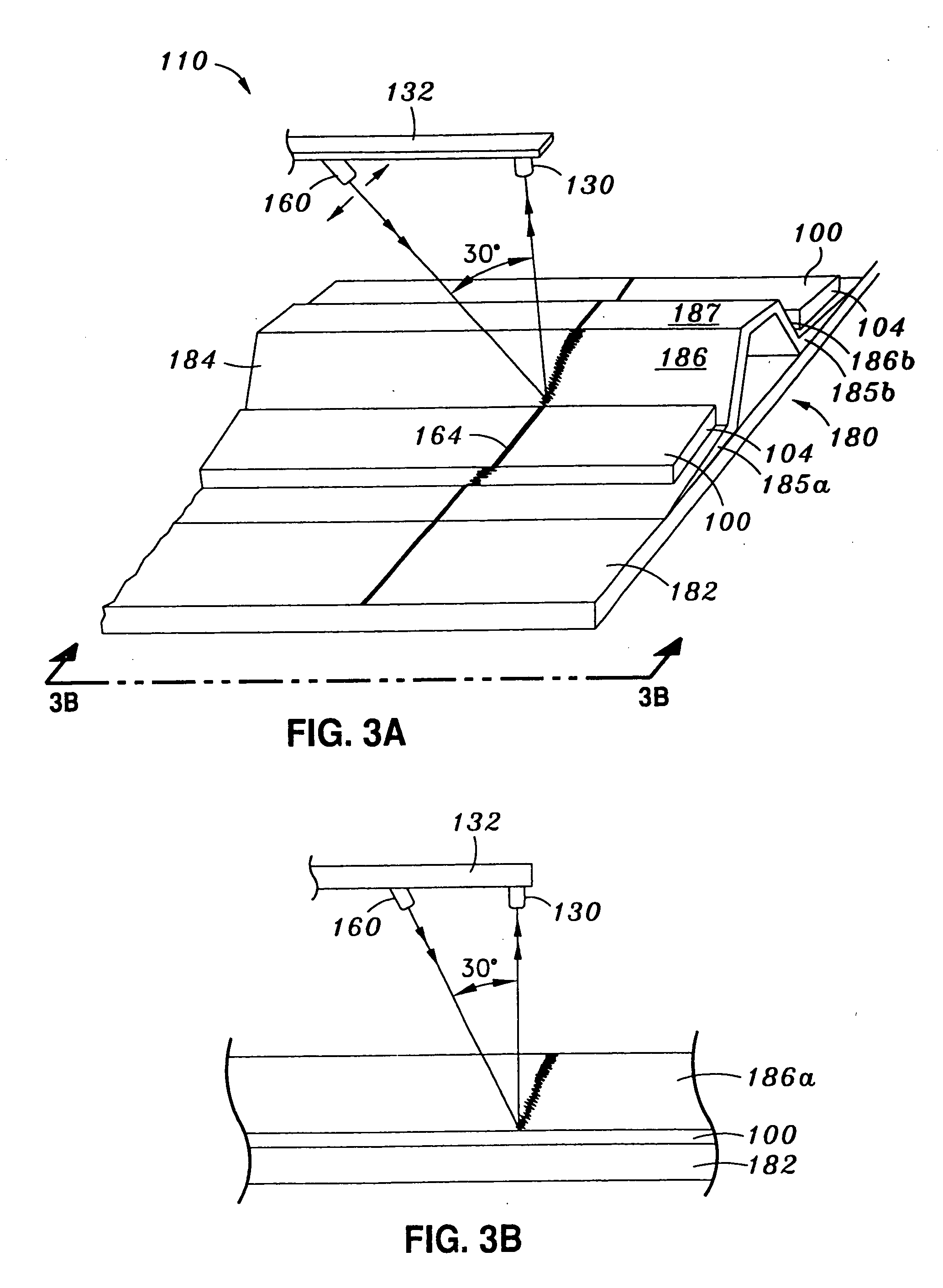

[0022] Referring now to the drawings wherein the showings are for purposes of illustrating preferred embodiments of the present invention only, and not for purposes of limiting the same, FIG. 1 and FIG. 2 illustrate one embodiment of a Z-form 100. As shown, the Z-form 100 comprises a plurality of Z-pins 102 embedded within a carrier 104. In one embodiment, the typical Z-pin 102 has a diameter of 0.011 inches and a length of 0.5 inches and is made out of a rigid material such as stainless steel, titanium, copper, graphite, epoxy, composite, glass, carbon, or the like. Typically, the manufacturer embeds an array of Z-pins 102 within the carrier 104, which is often made of a foam-like material, for shipping purposes. In one embodiment, the manufacturer embeds the Z-pins 102 at a density of 400 per square inch. As will be described in greater detail below, the Z-form 100 is positioned on an uncured composite structure, and an insertion tool moves the Z-pins 102 out of the carrier 104 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| second angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com