Building structure with purlin to beam connection

a technology of purlin and beams, applied in the direction of roofs, towers, buildings, etc., can solve the problems of affecting the quality of construction, labor and time, and consuming substantial amounts of material, and achieve the effect of reducing the amount of high-cost manual and skilled labor, high speed and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

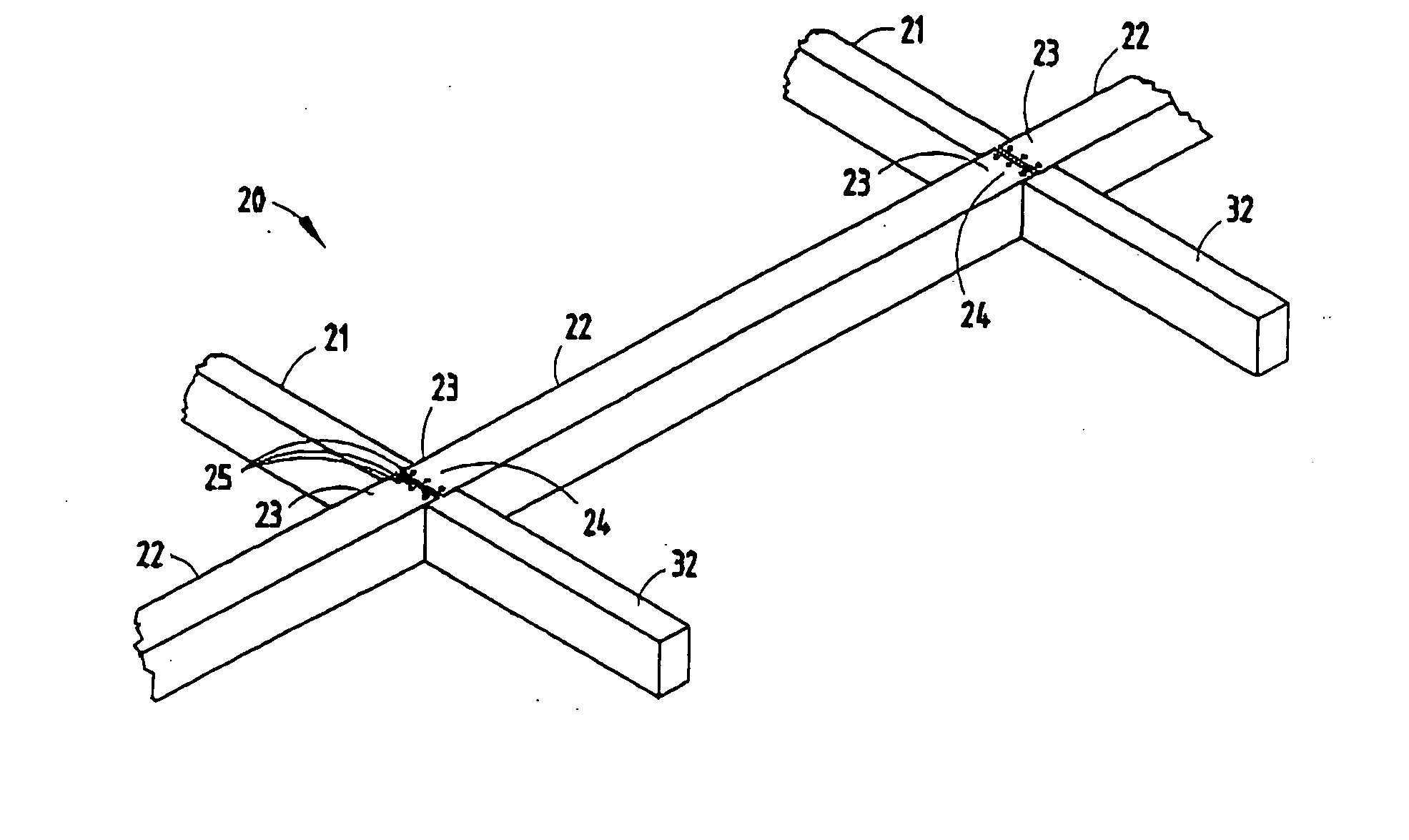

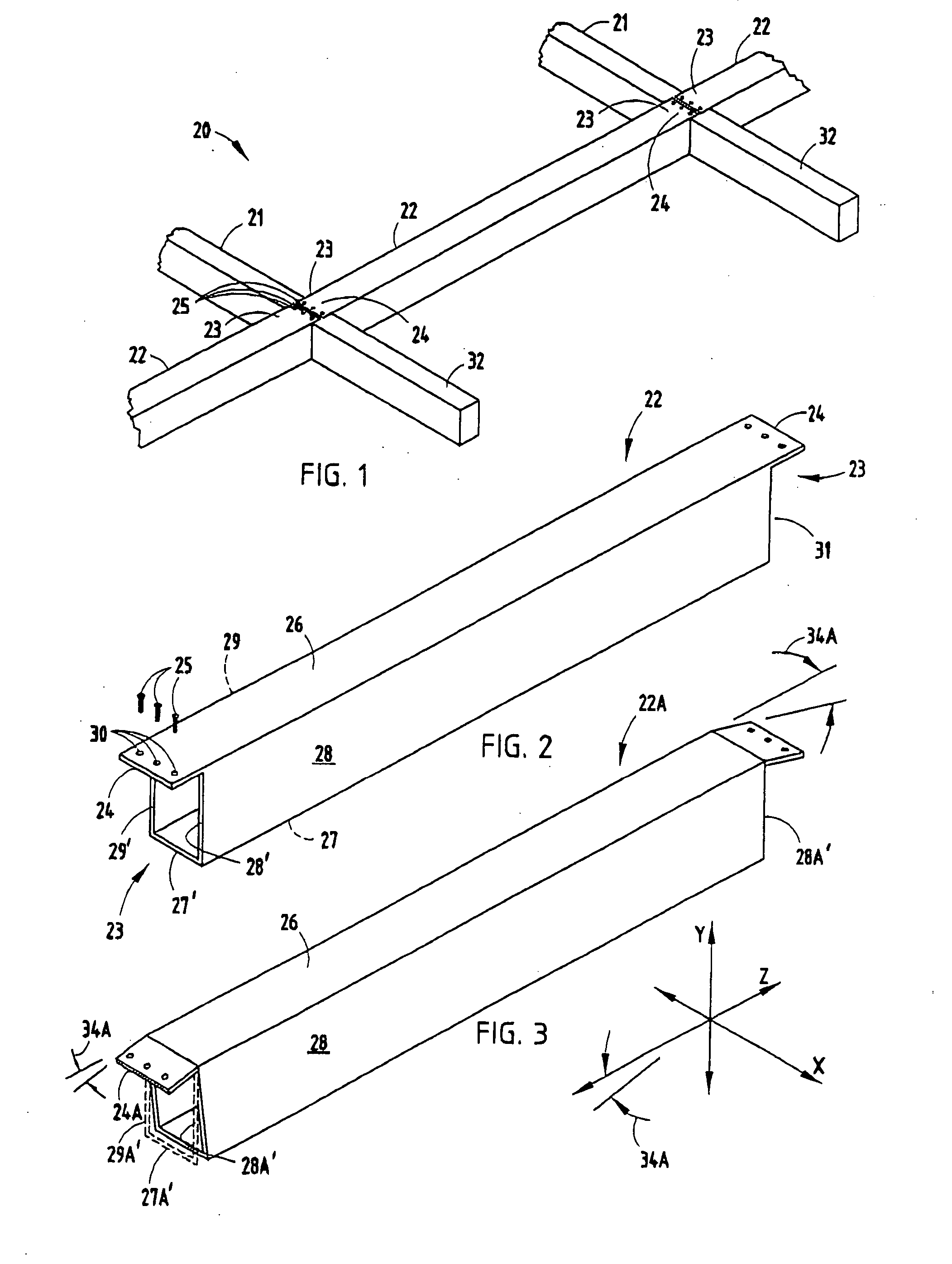

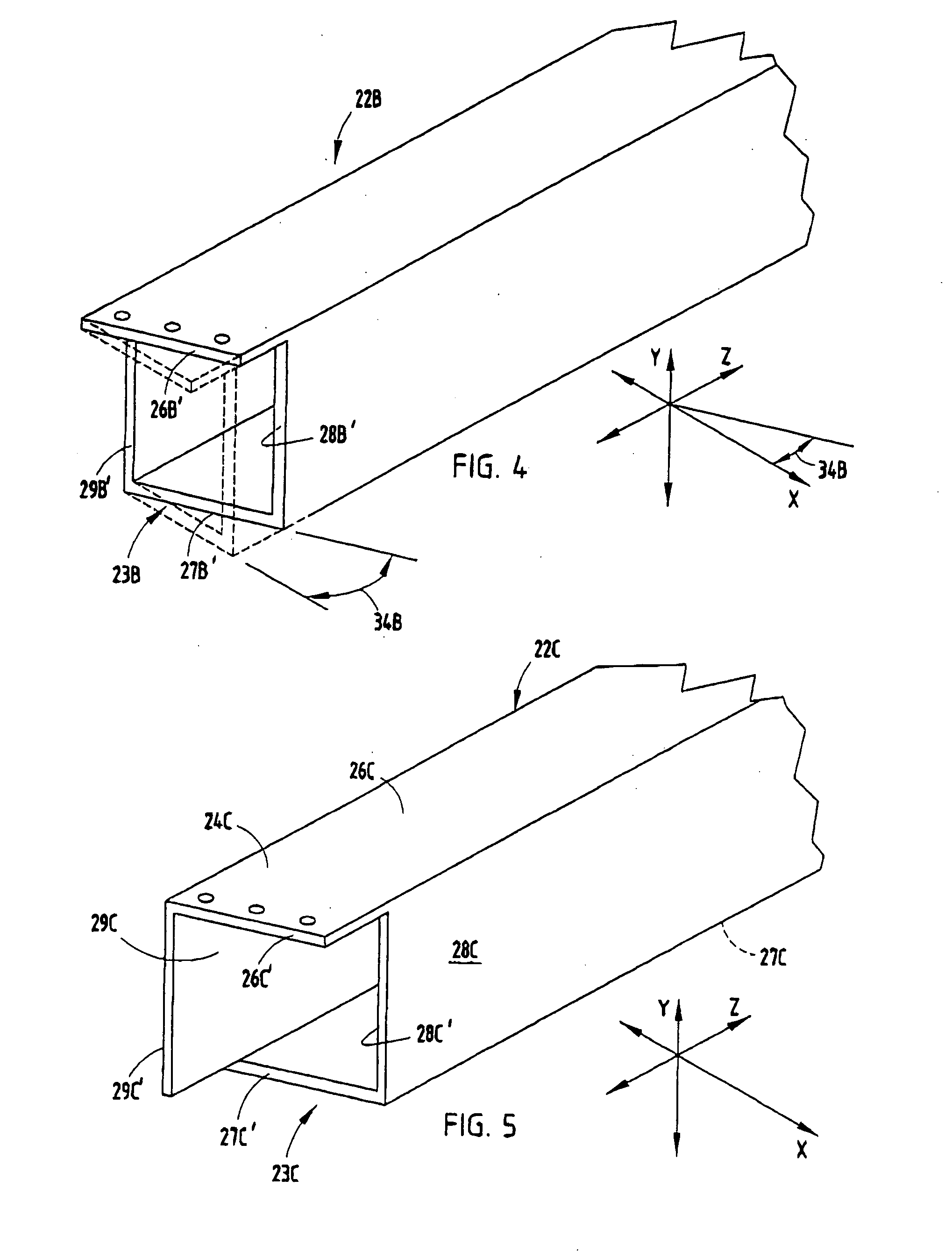

[0027] A metal frame 20 (FIG. 1) for a building structure includes one or more structural beams 21, and a plurality of tubular purlins 22 attached to the beams 21 to stabilize the beams 21 to form a rigid building structure, such as the illustrated roof frame structure. The tubular purlin 22 includes configured ends 23 forming a concave recess 23′ shaped to mateably engage a side of the beams 21 and further includes an attachment tab 24 extending longitudinally from the configured end 23 to a distance equal to about half of a width of the beam21. The configured end 23 and the attachment tab 24 both are integrally formed from material of the tubular purlin 22, as described below. The structural attachment tab 24 forms an arm that supports the configured end 23 on the structural beam 21 and structurally attaches the tubular purlin 22 to the structural beam 24 via a plurality of threaded screws 25 (three screws being illustrated).

[0028] The purlin 22 (FIG. 2) is a structural tube made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com