Sheet supply device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

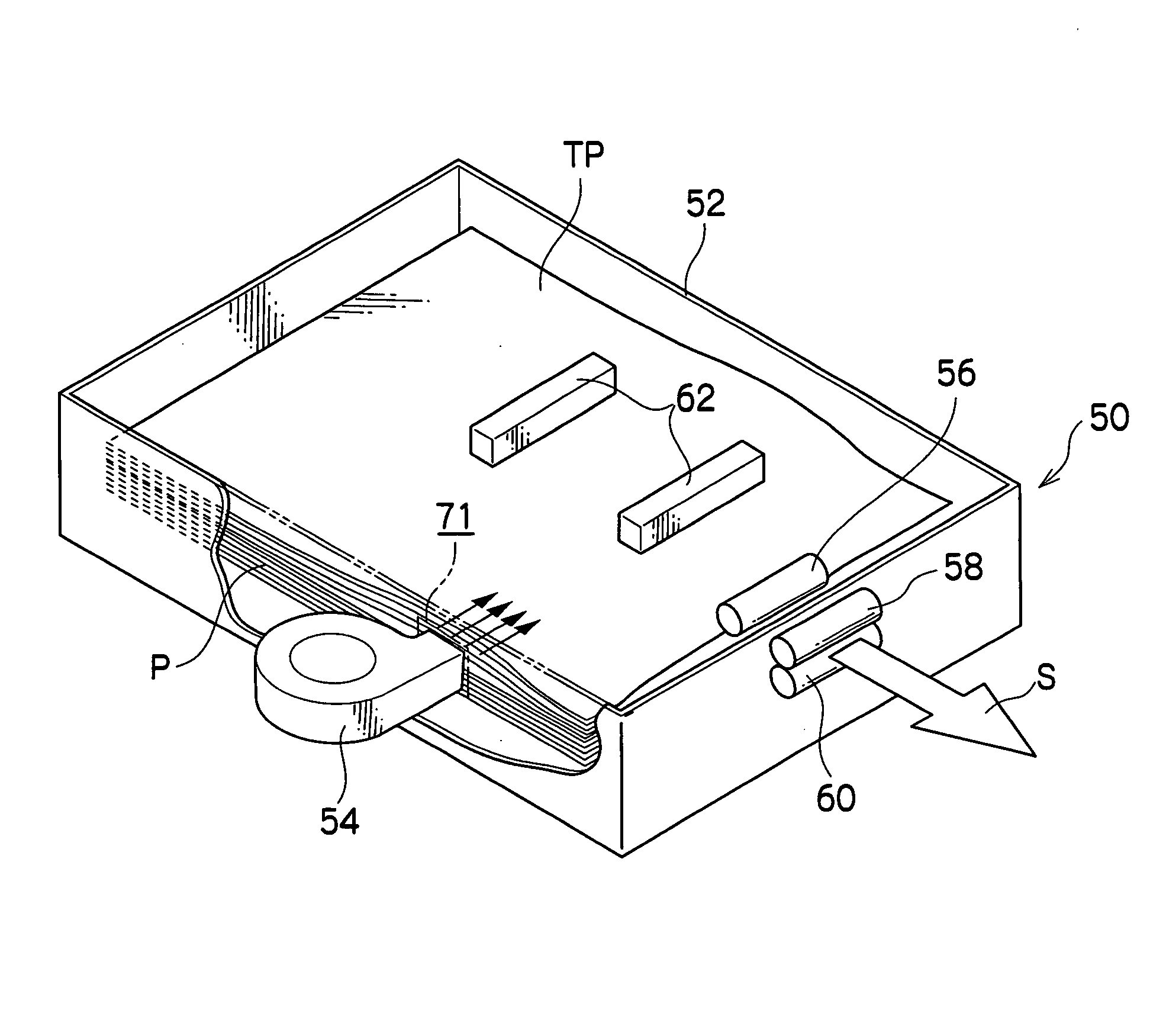

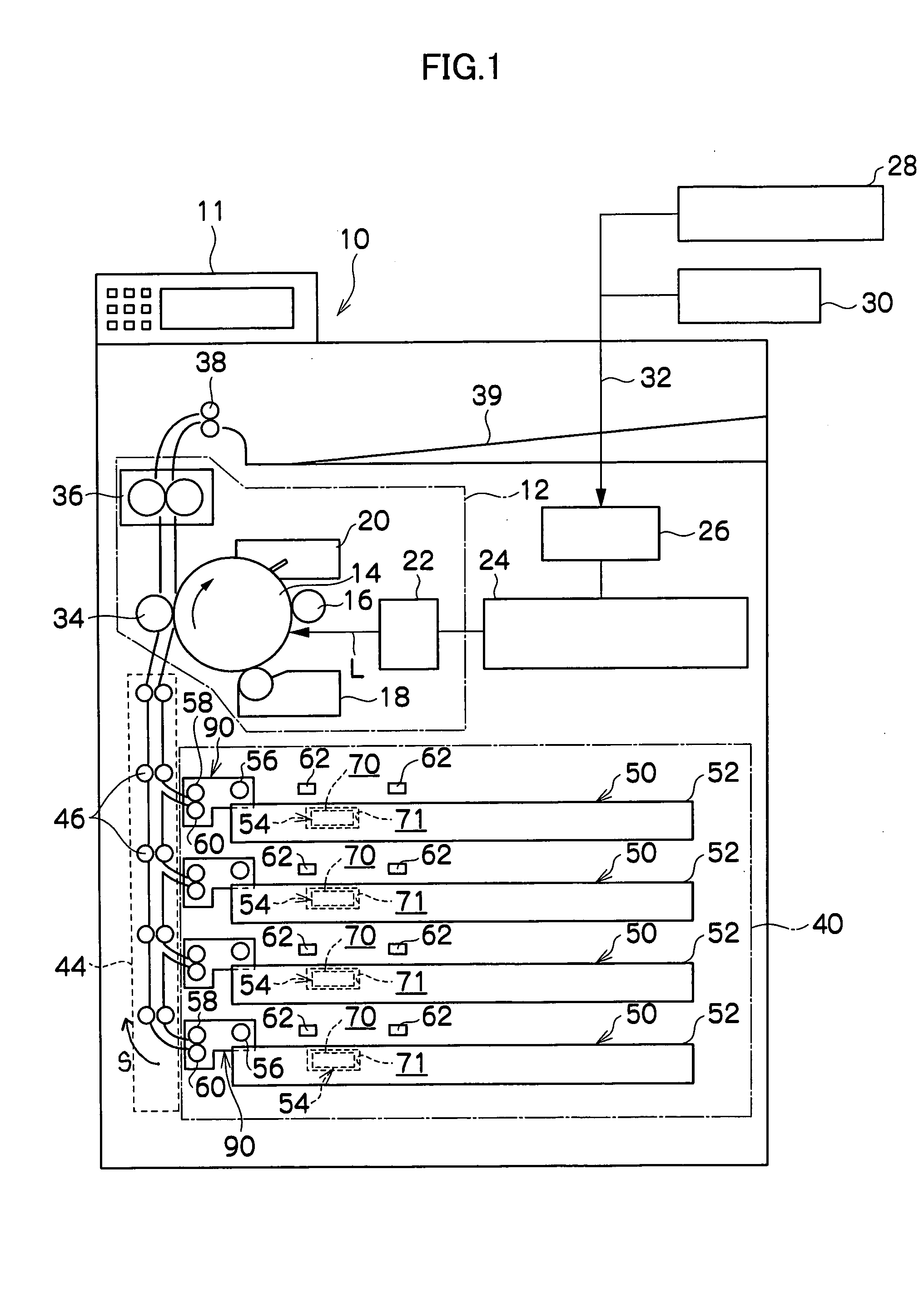

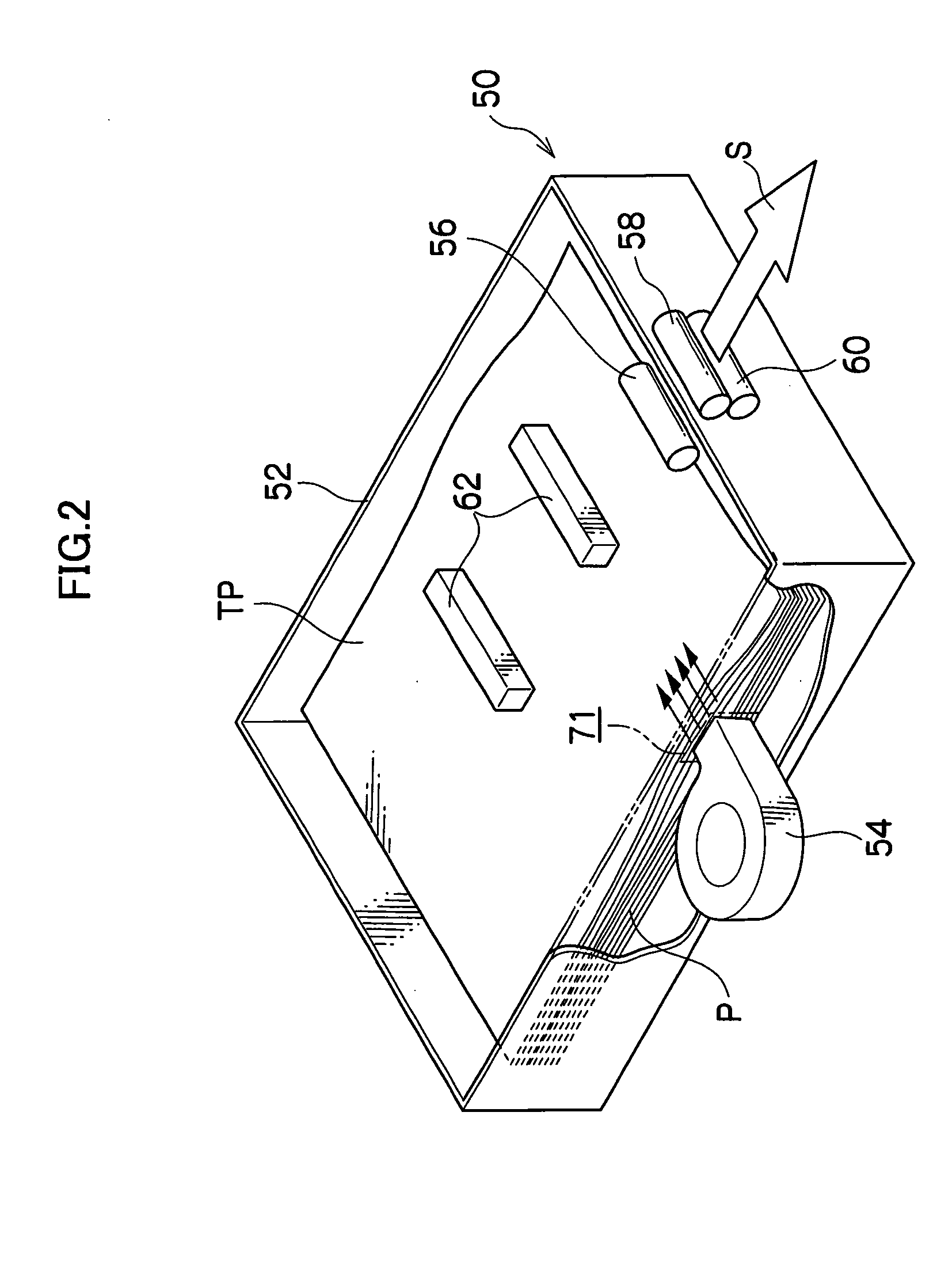

[0040] An image forming apparatus having a sheet supply device according to embodiments of the present invention will be explained below with reference to the drawings. As an image forming system in the image forming apparatus, a known electrophotographic process is used.

[0041] A structure of the image forming apparatus 10 and a summary of image formation will be described first, and a main section of the invention will be explained thereafter. As sheets P on which an image is formed, sheets with a smooth surface are used such as normal paper or coated paper, the surface of which undergoes a coating process in order to provide whiteness and gloss.

[0042] As shown in FIG. 1, the image forming apparatus 10 has a control unit 24 that controls the entire image forming apparatus 10 and stores various information therein. An operation panel 11 is provided on an upper portion of the apparatus. When a user operates the operation panel 11, the control unit 24 controls the apparatus in accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com