Method of making insole and insole made thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

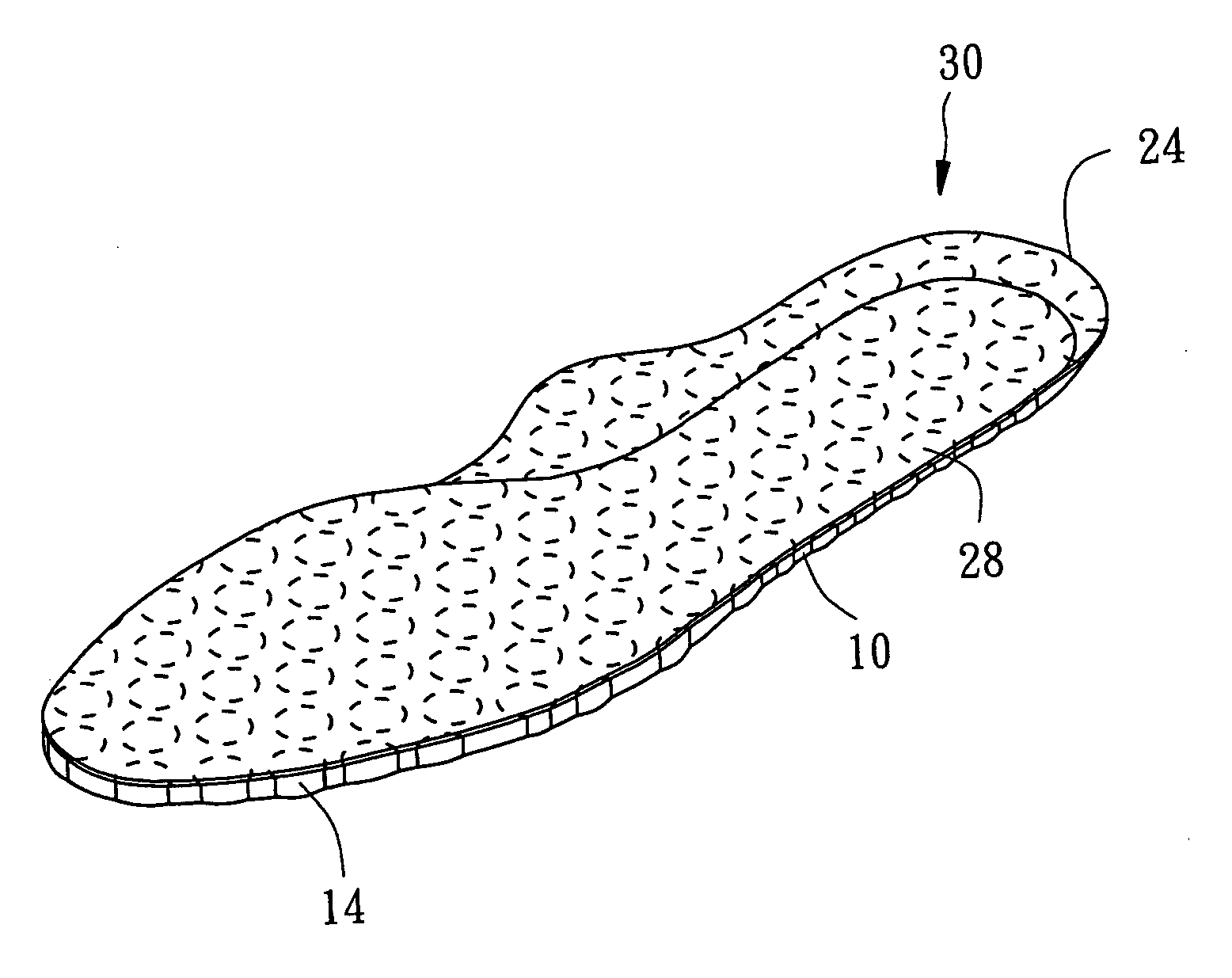

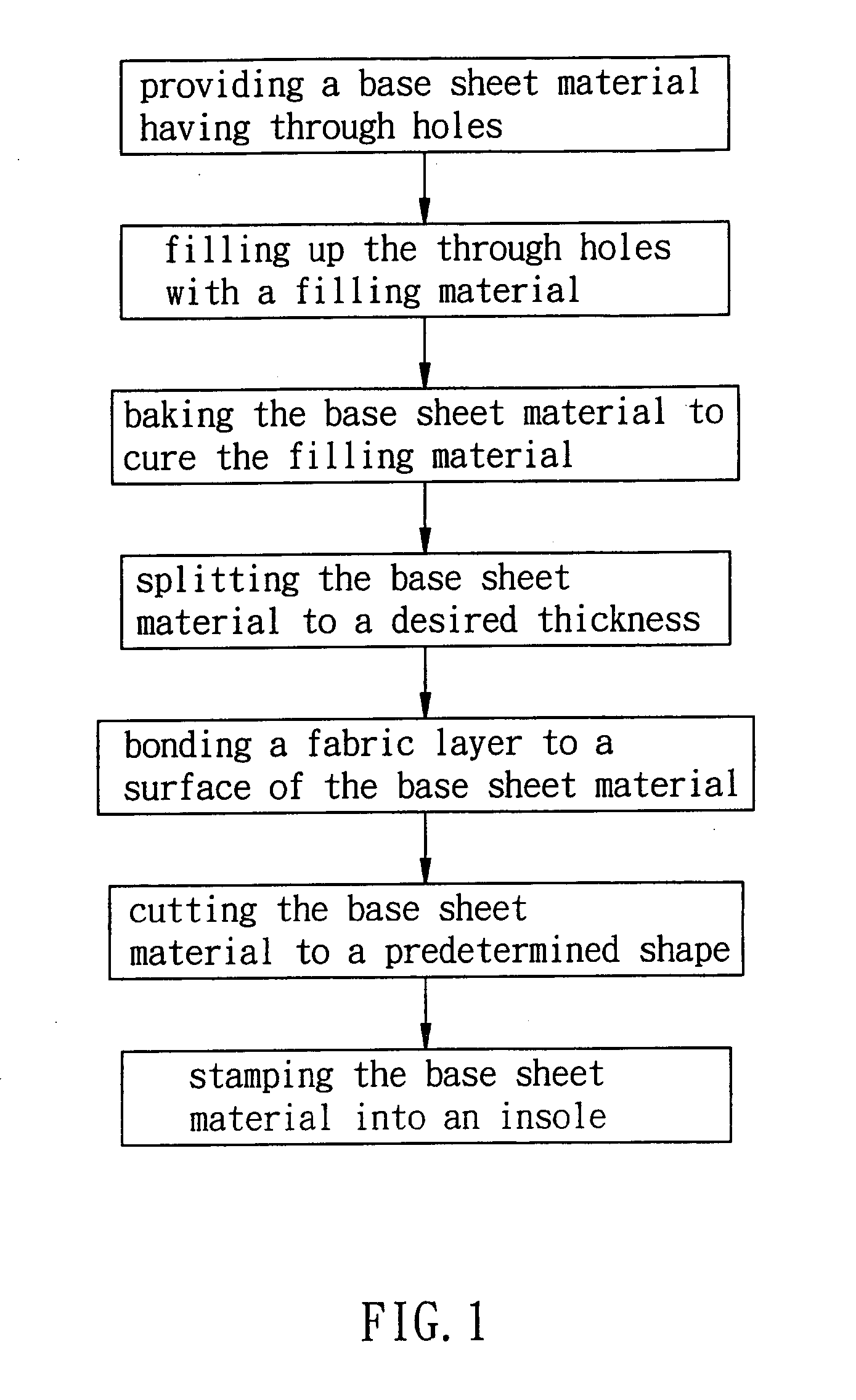

[0016] Referring to FIG. 1, a method of making an insole in accordance with the present invention includes the steps of (a) material preparation, (b) filling material immersion, (c) baking, (d) material splitting, (e) fabric bonding, (f) cutting and baking, and (g) stamping.

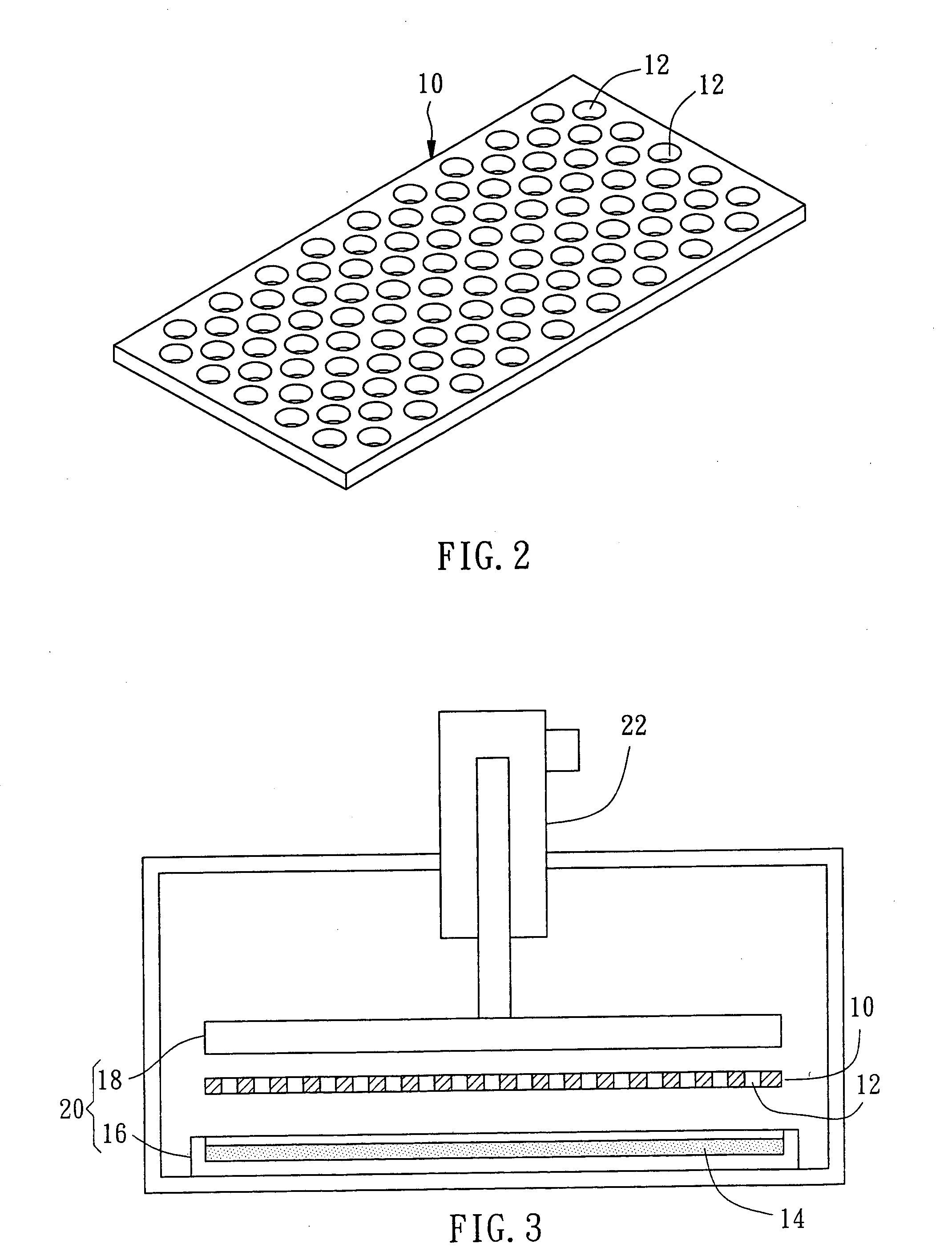

[0017] Referring to FIG. 2, a base sheet material 10 is provided during step (a) material preparation. The base sheet material 10 is molded from a polymeric compound, for example, EVA (Ethylene Vinyl Acetate), having a plurality of circular through holes 12 through the top and bottom sides thereof.

[0018] Referring to FIGS. 3 and 4, after step (a) material preparation, it proceeds to step (b) filling material immersion where the base sheet material 10 is immersed in a fluid filling material 14, enabling the filling material 14 to fill in the through holes 12. The filling material 14 is a different polymeric compound. According to this embodiment, the filling material 14 is latex. The filling material 14 is fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com