Railroad vehicle with energy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

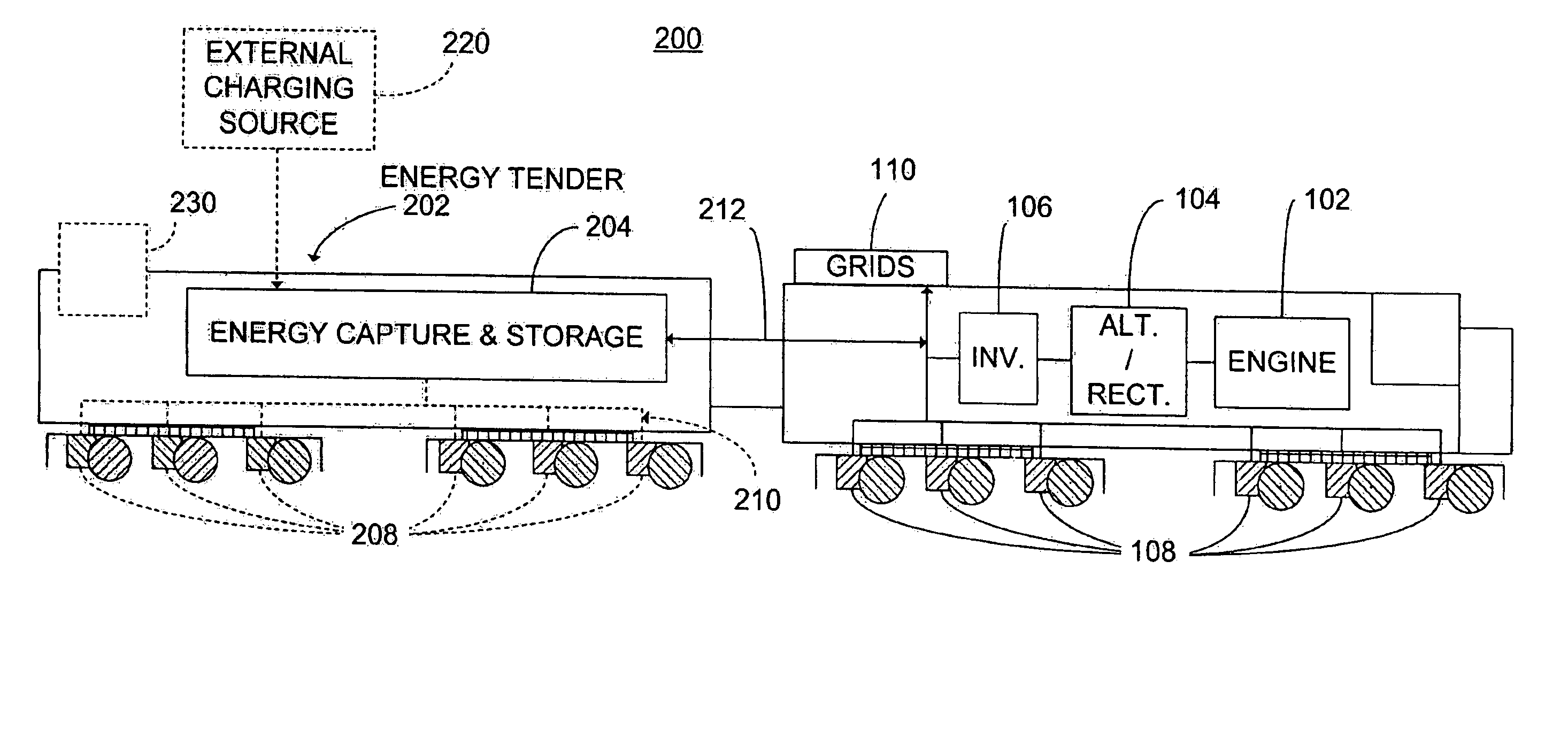

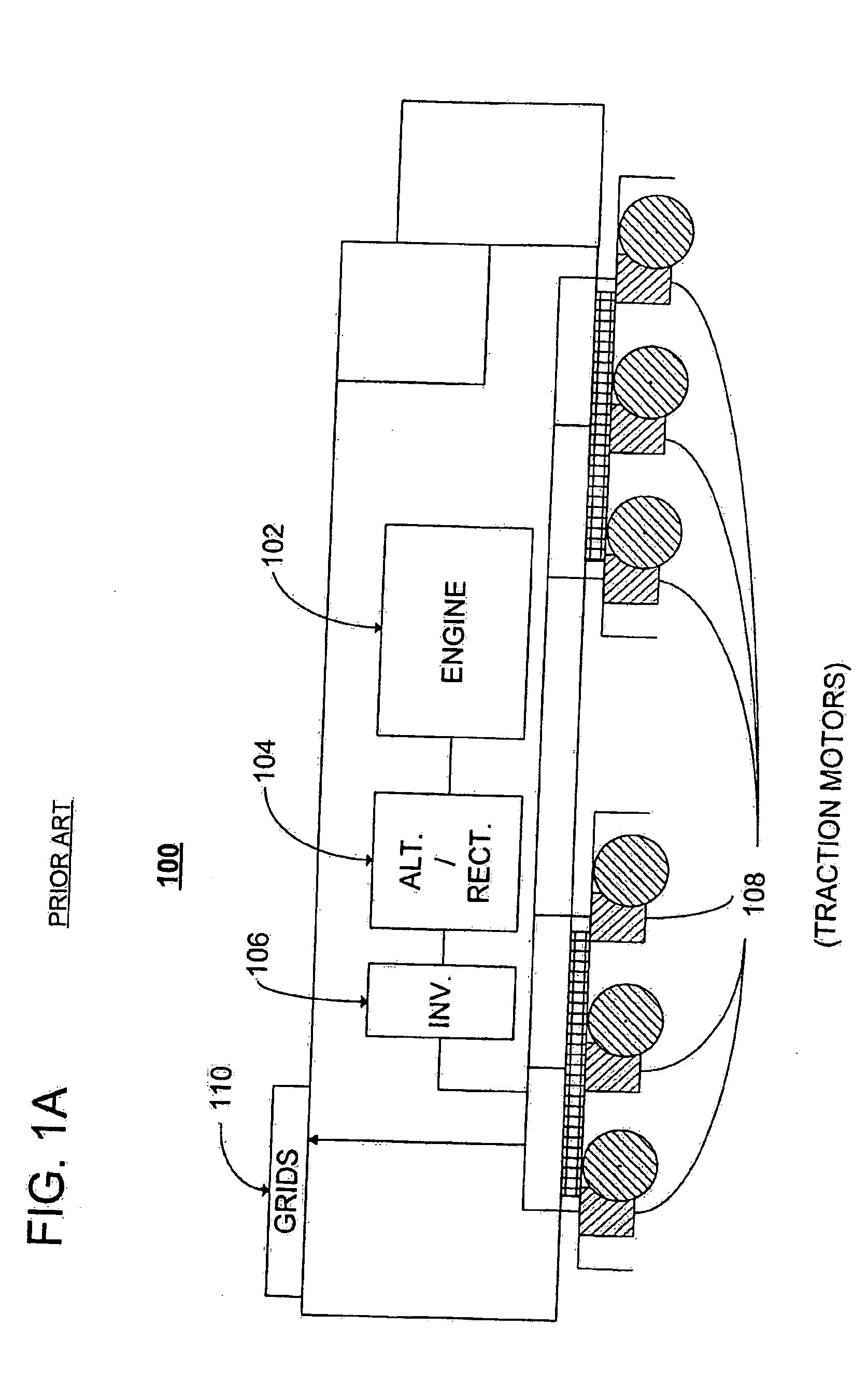

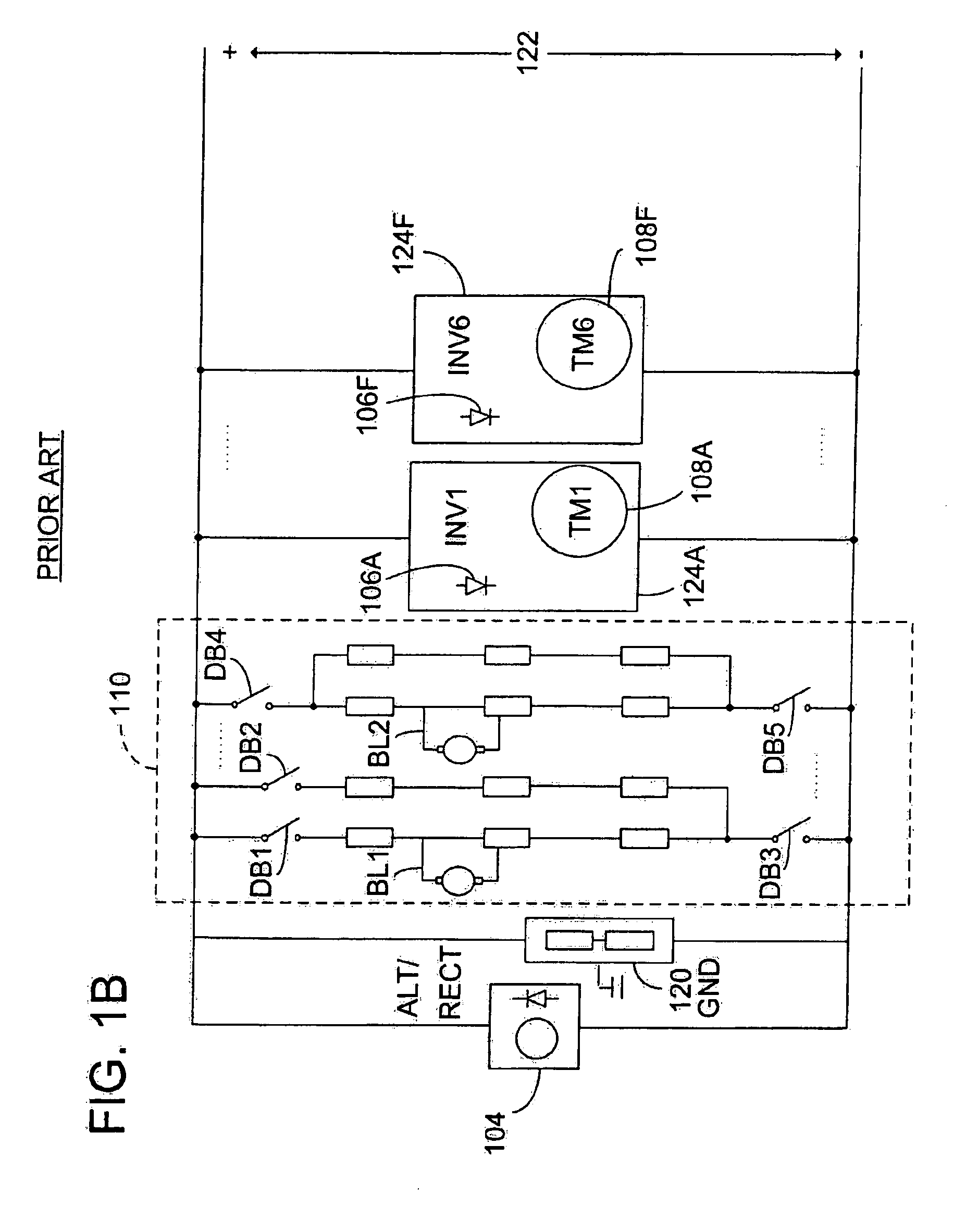

[0039] The art of hybrid locomotive energy systems has advanced through the inventions described in previously filed applications in this chain of patent applications. These focused on locomotives and tender cars that advantageously include the capacity to generate electrical power from a dynamic braking operating mode, to store such power, and to use such power at a later time during a motoring operating mode. Systems in such previously filed applications generally referred to components of a single hybrid energy railroad vehicle. The present application focuses on a class of multipurpose regenerative energy railway vehicles that is for carrying freight as one of its primary functions, and that also, through the components described herein, has power generation capability. Such railroad vehicles comprise a drive unit, such as a traction motor, operable in three movement-type operating modes: coasting; dynamic braking; and motoring. In some embodiments of such railroad vehicles, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com