Vertical outrigger leg

a technology of vertical outrigger and work machine, which is applied in the direction of soil shifting machine/dredger, vehicle maintenance, transportation and packaging, etc., can solve the problems of limited height of outriggers at their furthest point from the chassis, unique design of outrigger assembly, and limited height of outriggers. , to achieve the effect of increasing vertical lift, facilitating operation, and facilitating maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

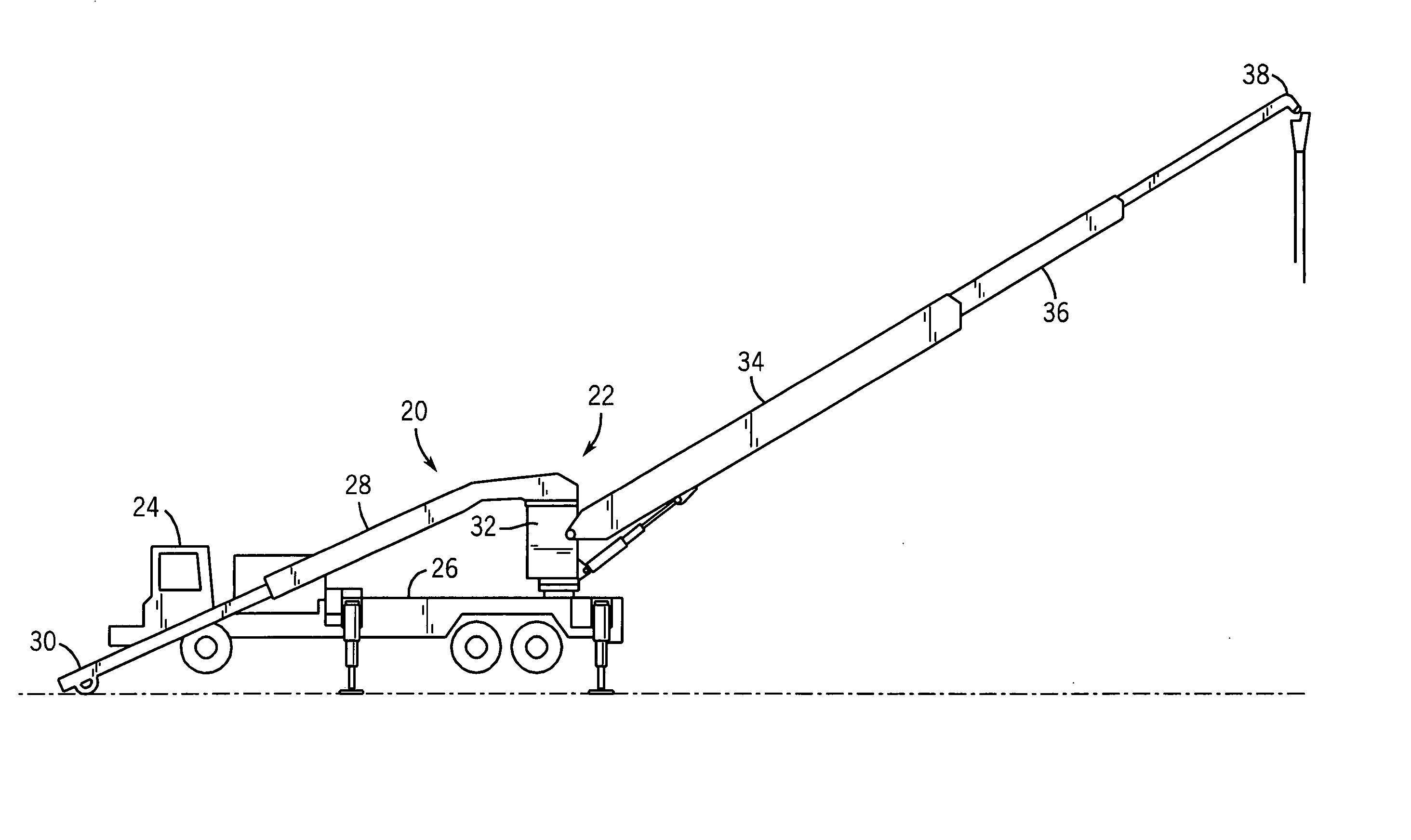

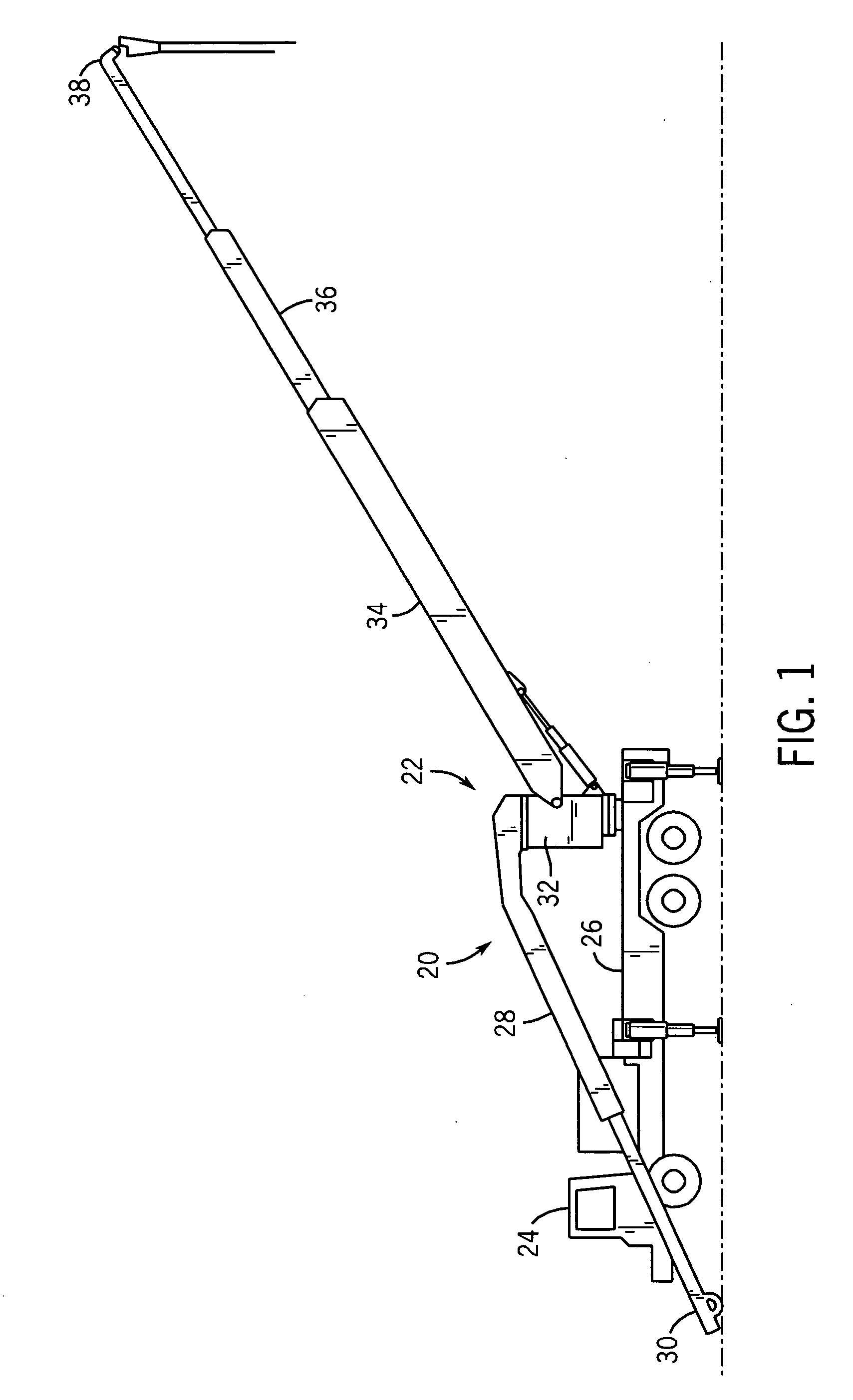

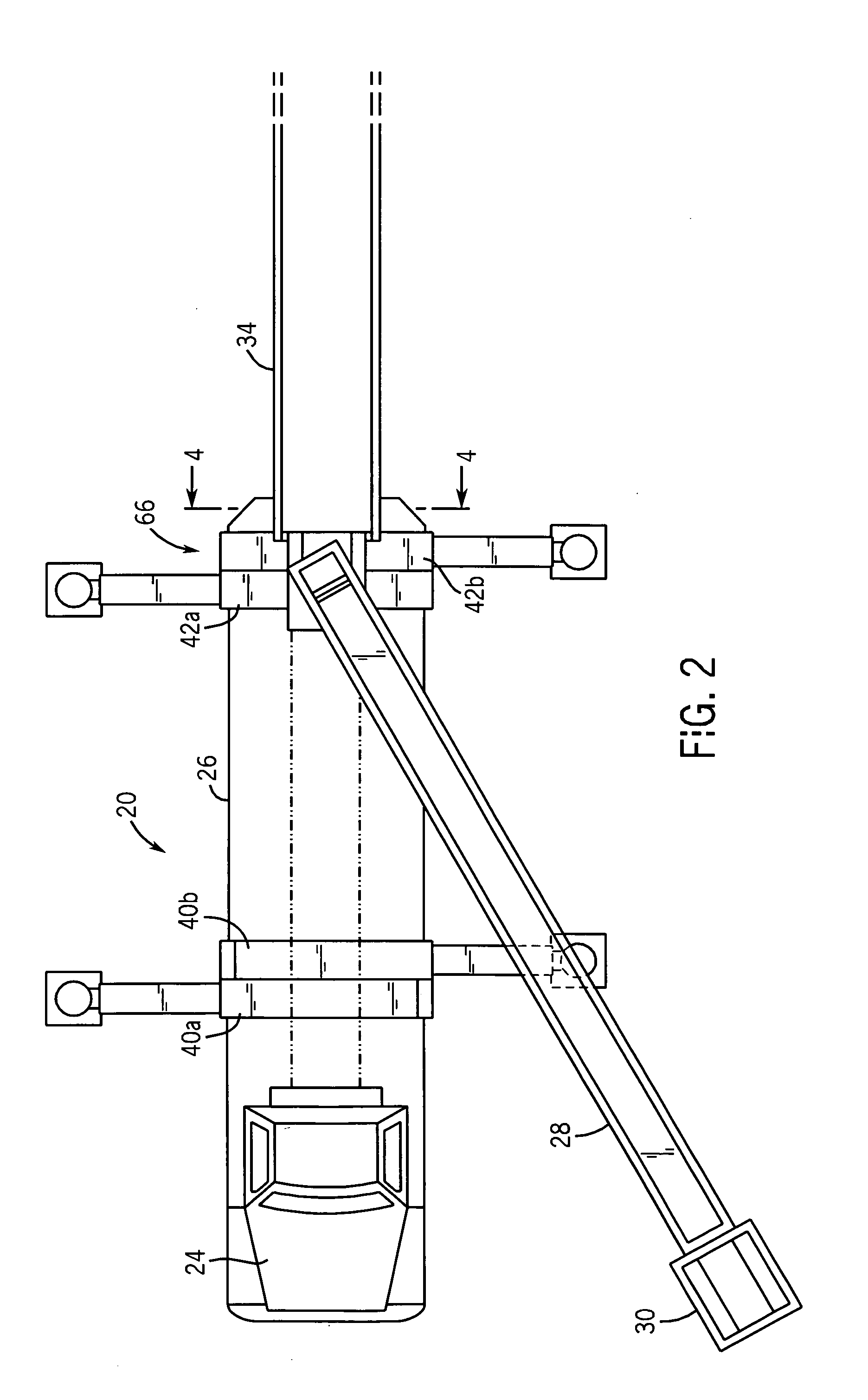

[0024] A mobile work machine, such as a self-propelled vehicle 20 including a vehicle-mounted conveyor system 22 for transporting an aggregate material such as concrete is best shown in FIGS. 1 and 2. The vehicle 20 includes a conventional cab 24 and a torque tube 26. The vehicle 20 is of a size such that it does not exceed the legal dimensional limits for over the highway travel.

[0025] The conveyor system 22 includes an in-feed conveyor assembly 28 that receives the supply of aggregate material, such as concrete, from a supply source 30 and transports the material upward along a moving in-feed conveyor belt. The in-feed conveyor assembly 28 is rotatable about the vehicle 20 such that the in-feed conveyor assembly 28 can receive the supply of material at various locations around the vehicle 20.

[0026] The conveyor system 22 includes a main turret 32 that is rotatably mounted to the torque tube 26 of the vehicle 20. A discharge conveyor assembly 34 is pivotally mounted to the main t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com