Method and distributor for air-laying of fibers

a distributor and fiber technology, applied in the field of airlaying fiber distributors, can solve the problems of high production rate, high cost of finished fiber products, and relatively long synthetic fibers, and achieve the effect of saving costs and high production ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

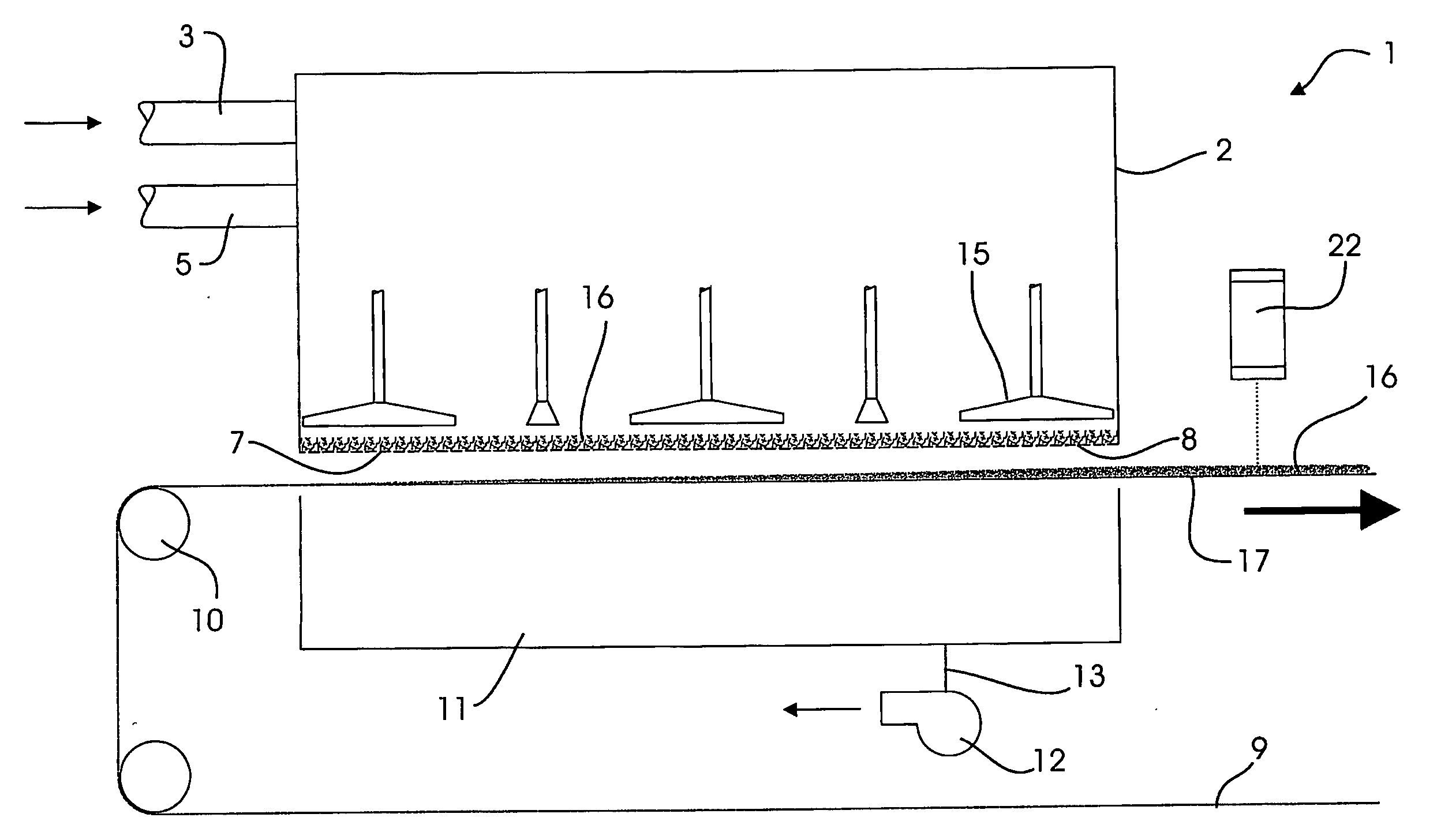

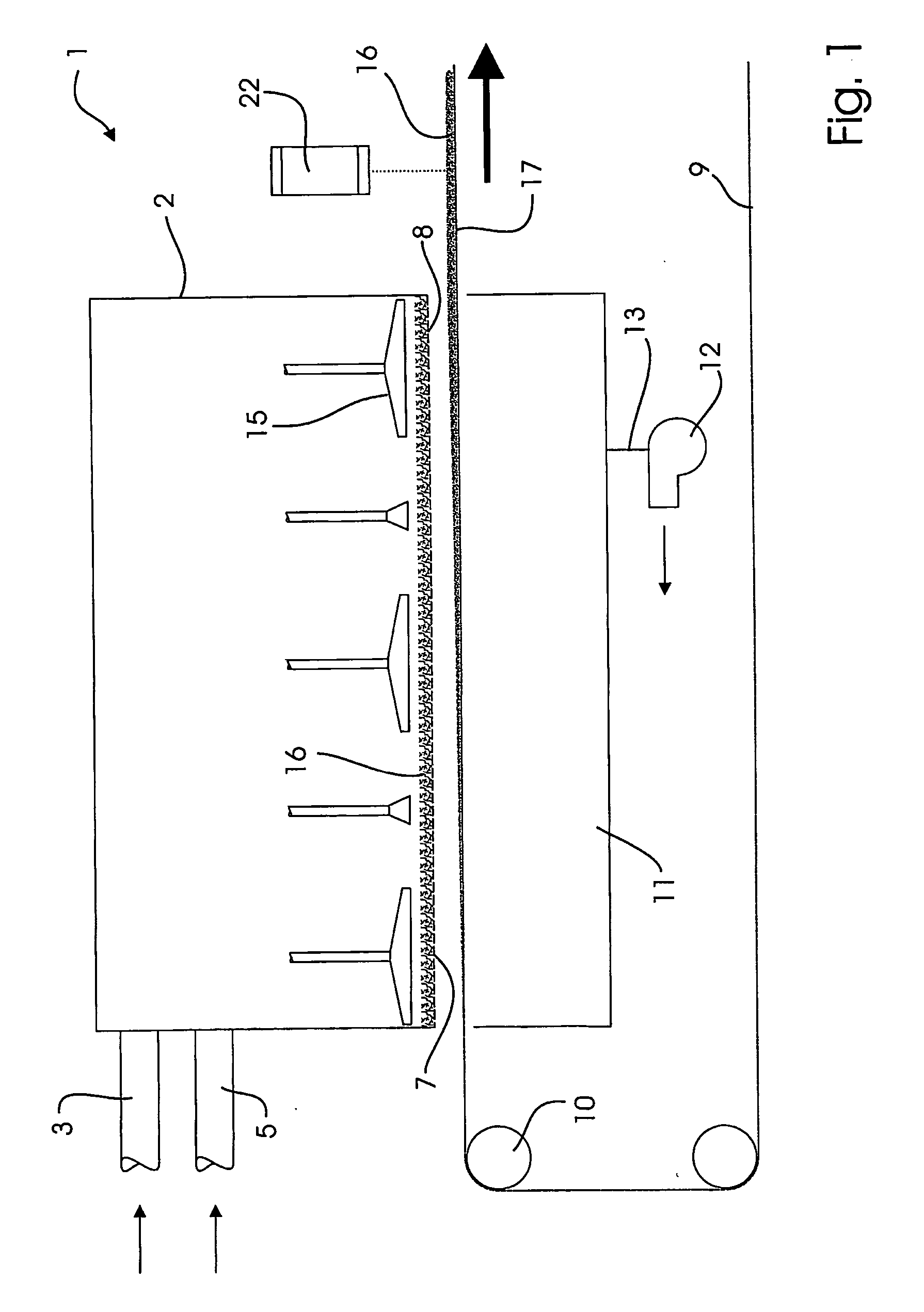

[0022] The following detailed description is based on the assumption that the fibers consist of a blend of relatively short cellulose fibers and relatively long synthetic fibers.

[0023] The fiber distributor 1 comprises a forming head 2 with an inlet 3 for the cellulose fibers 4 and another inlet 5 for the synthetic fibers 6. These inlets 3,5 admit the respective fibers 4,6 to enter the forming head in air streams in the direction of the arrows shown.

[0024] The forming head has a perforated bottom 7 with openings 8. Below the bottom is arranged an endless, air pervious forming wire 9 running, during production, over rolls 10 in the direction shown by the arrow. Only part of the forming wire is shown in FIGS. 1 and 2.

[0025] Below the forming wire is placed a suction box 1. An evacuating pump 12 serves for producing a negative pressure in the suction box via an air duct 13.

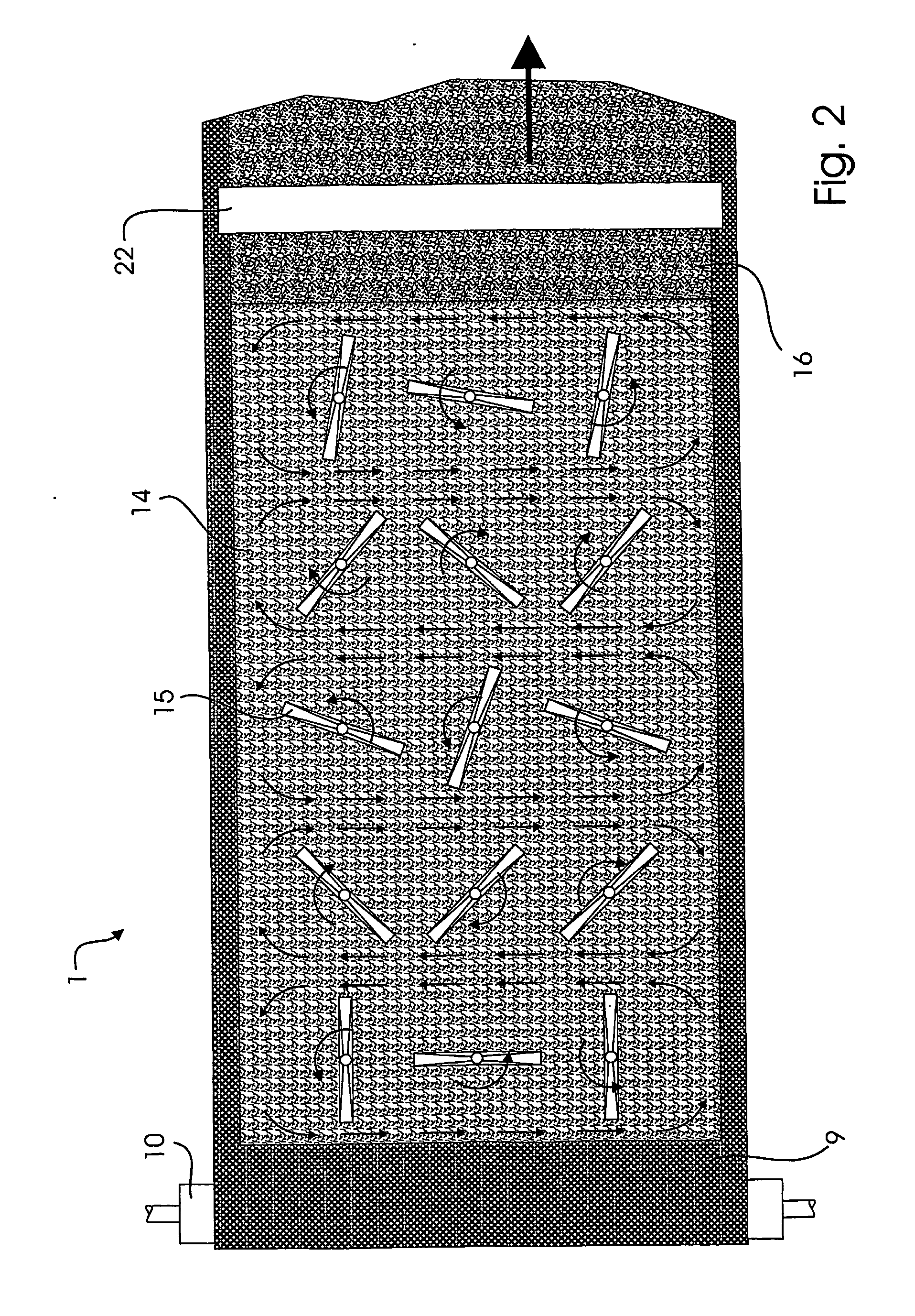

[0026] At a distance above the perforated bottom are, in this example, mounted five rows 14, each having three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com