Abrasive articles and methods for making them

a technology of abrasives and foam articles, applied in the direction of thin material processing, ways, textiles and paper, etc., can solve the problem of painting the quality of any image applied to films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

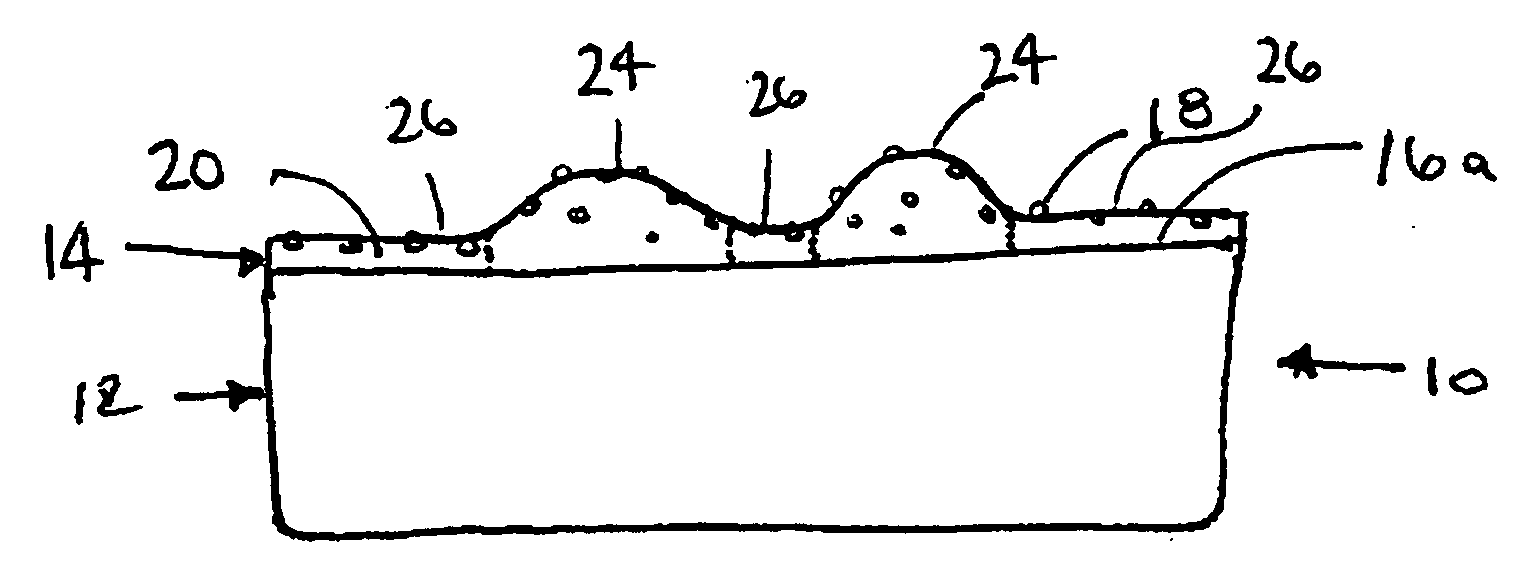

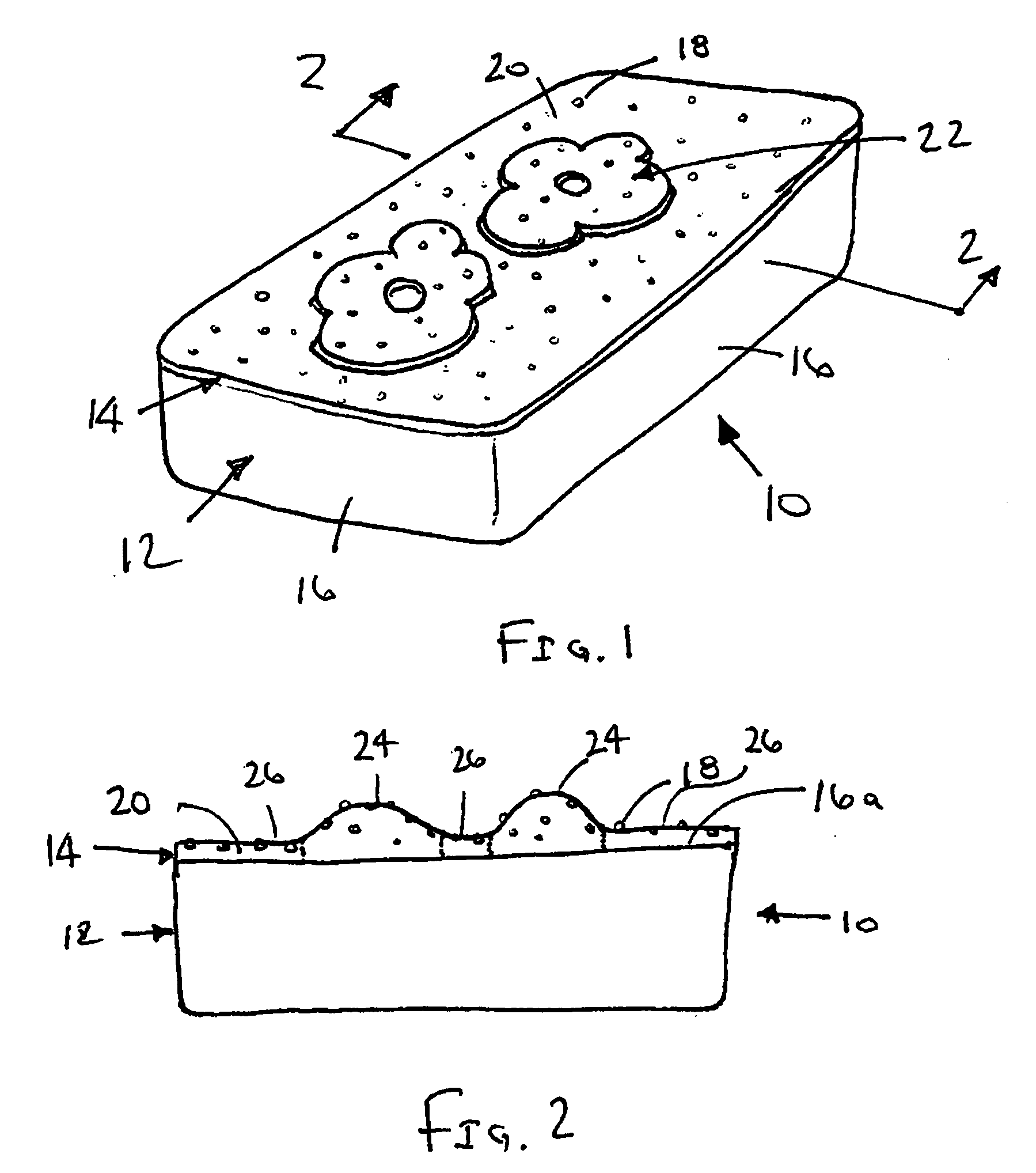

[0030] Turning to the drawings, FIGS. 1 and 2 show an exemplary embodiment of an abrasive tool 10, in accordance with one aspect of the present invention. The tool 10 may be a handheld tool for personal grooming, e.g., a tool for filing and / or buffing fingernails or toenails, a pumice stone for removing calluses or excess skin, and the like. Alternatively, the tool 10, may be used for buffing and / or cleaning objects, such as furniture, dishes, and the like.

[0031] Generally, the tool 10 includes a base layer 12 including one or more surfaces 16, and an abrasive layer 14 on at least one of the surfaces 16. As shown in FIGS. 1 and 2, the abrasive layer 14 is only provided on an upper surface 16a of the base layer 12. Alternatively, two or more surfaces of the base or core layer may include an abrasive layer.

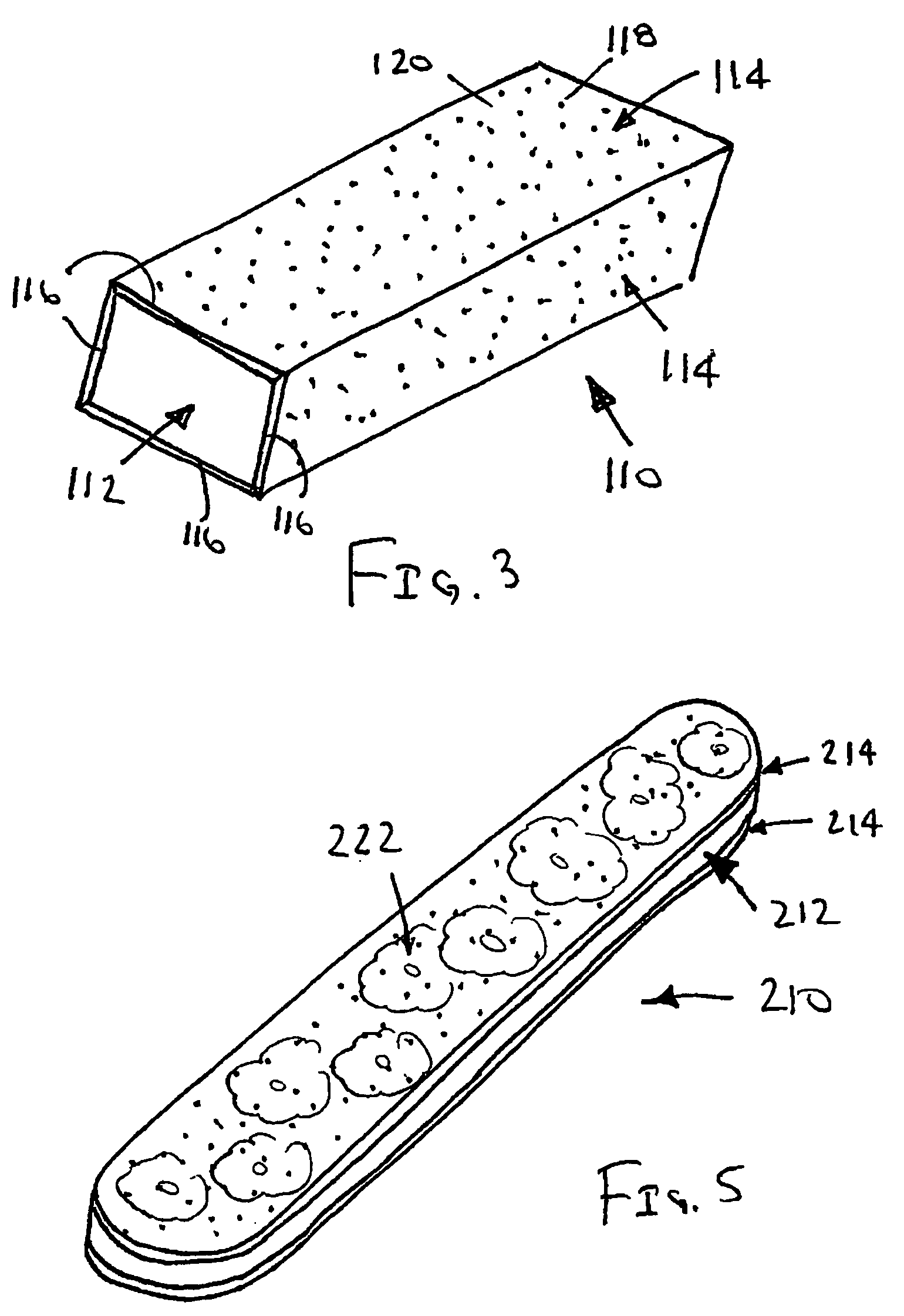

[0032] For example, as shown in FIG. 3, a nail tool 110 may include a base or core layer having a square, rectangular, or other cross-section, and an abrasive layer 114 on two or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com