Shock absorbing and cooling structure

a technology of shock absorption and cooling structure, which is applied in the field of shock absorption structure, can solve the problems of limited success in the field of plastic structure impact absorption, foam does not allow heat to dissipate from the head or body, etc., and achieve the effect of dissipation of heat through the bas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

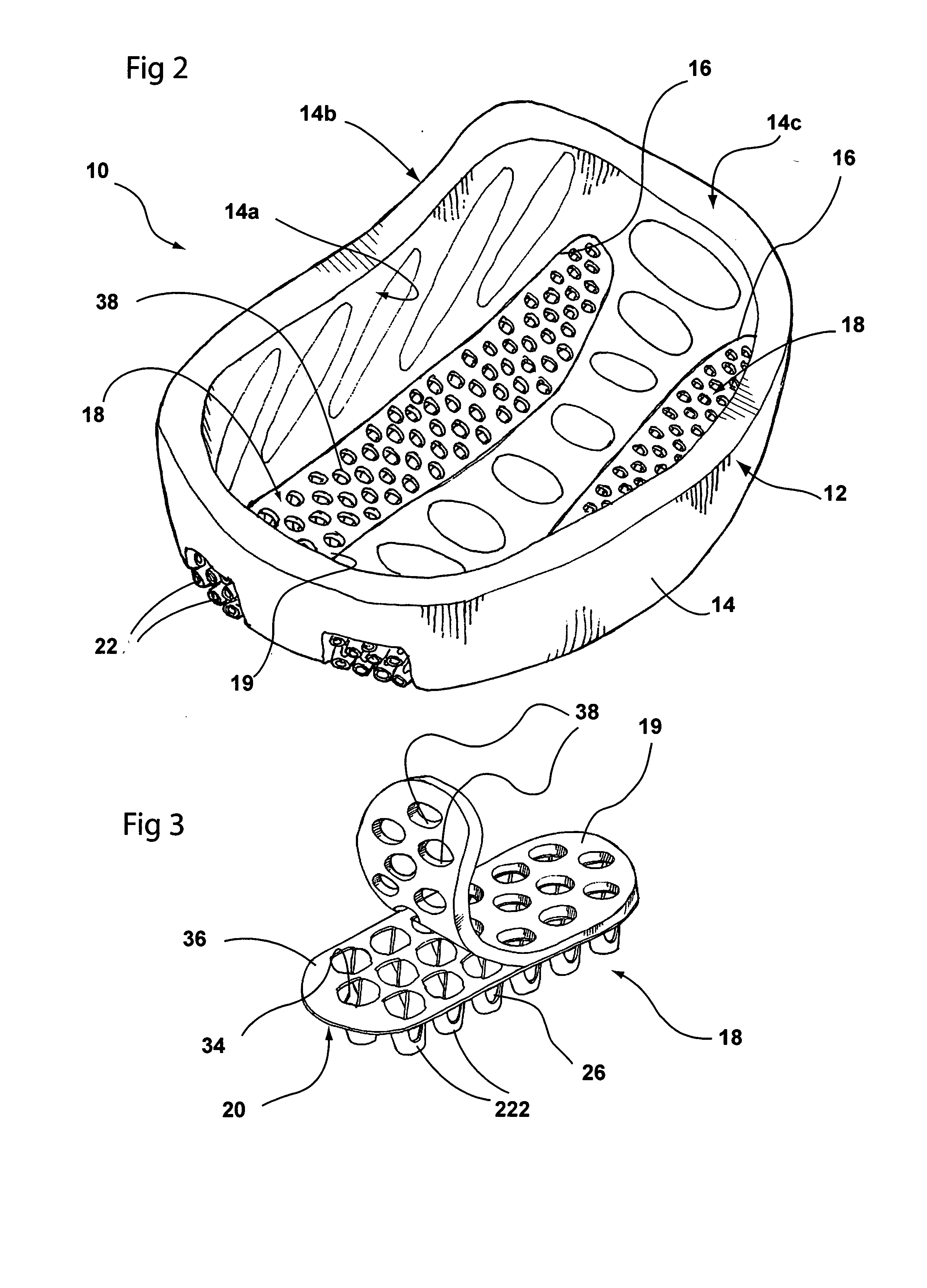

[0027]FIG. 5 illustrates the insert in accordance with the present invention, and being generally indicated at 118. Insert 118 comprises a foam member 119 and generally planar surface 120 adhesively connected together. Disposed on the planar surface 120 is a plurality of upstanding, hollow support members 122 extending outwardly from the planar surface 120. Foam member 119 is manufactured from the same material as the base 12. The planar surface 120 and convex sidewalls 124 are made of a suitable flexible plastic material such as a thermoplastic polymer like polyethylene. As such, the planar surface 120 and support members 122 are able to flex when a force is applied to them.

[0028] Support members 122 include sidewalls 124 that are preferably made of the same flexible plastic material as the planar surface 120, and are integral with the planar surface 120. Each of the support members 122 includes at least one opening 126 that define air passages within the insert 118 to allow air to...

third embodiment

[0031]FIG. 6 illustrates the insert in accordance with the present invention and generally indicated at 218. Insert 218 comprises a foam member 219 and a generally planar surface 220 that are adhesively connected together. As before, foam member 219 is manufactured from a softer foam material than base 12. Disposed on the planar surface 220 is a plurality of upstanding, hollow support members 222 extending outwardly from the planar surface 220. The planar surface 220 are made of a suitable flexible plastic material such as a thermoplastic polymer like polyethylene. As such, the planar surface 220 and support members 222 are able to flex when a force is applied to them.

[0032] Support members 222 include sidewalls 224 that are preferably made of the same flexible plastic material as the planar surface 220, and are integral with the planar surface 220. Each of the support members 222 includes at least one opening 226 that define air passages within the insert 218 to allow air to flow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com