Collapsible step and extension ladder

a ladder and step technology, applied in the field of collapsible ladders, can solve the problems of complicated design and costly manufacturing, and achieve the effects of preventing tipping and damage to the fascia siding or roof of a home, preventing damage to the fascia, and easy material hauling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

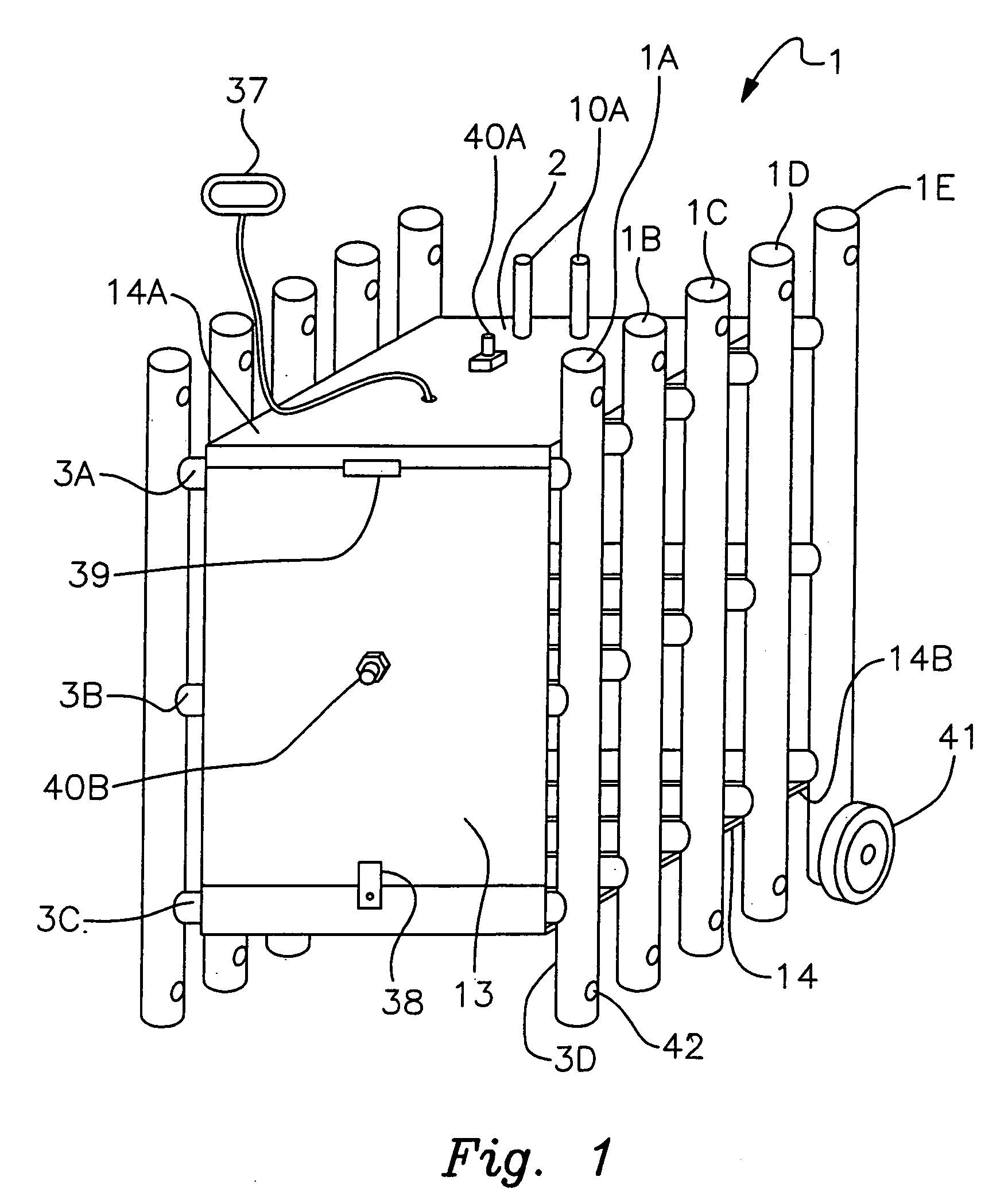

[0059] In the invention, the brackets are attached to the platform and surround at least the top of the extension arms. The locking screws may be either thumb screws to grip the extension arms or screws which penetrate the extension arms for a more permanent arrangement. The brackets are generally placed at the corners of the platform to provide maximum strength. The platform lies between the extension arms and the backboard rest against the collars.

[0060] The use of the hoist is shown in FIG. 6. This Figure is a side elevation view of the ladder of the present invention used with the hoist of FIG. 5A. This Figure shows a wall 9, a ground line 12, a ladder with a rail 22B resting on the ground at its bottom and against the wall 9 at its top, and the hoist shown in FIG. 5A. The components of the hoist that can be seen in this Figure include the extension arm 19A, the collar 17A, and the back stop 23B. Added to the ladder is a pulley 28 over which is placed a line 27. One end of the l...

second embodiment

[0063] In a second embodiment, the hoist 31 of FIG. 5C is almost identical to that of FIG. 5A except the left and right skids 26A and 26B are substituted for collars 17A and 17B. Only right skid 26B can be seen in FIG. 6. The skids are longer than the collars to that they can ride on the ladder rungs and the sled formed by the skids is narrower than the width of the ladder. therwise the operation of the two hoists is identical.

[0064] A variation which is within the spirit and scope of the invention is to include wheels on the hoist to facilitate raising the hoist on the ladder. The wheels include a ratchet which brake to prevent the hoist from going down unintentionally. The wheels may include a groove to grip the rails or may be doubled with one wheel on each side of a rail to grip the rails and prevent the hoist from shifting off of the ladder. The hoist ratchet is released after removing the load or when it is desired to bring a load down the ladder. A further improvement is to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com