Top-up container assembly comprising a dispensing cap, and a dishwashing product comprising the container assembly

a container assembly and top-up technology, applied in the direction of rigid containers, pliable tubular containers, transportation and packaging, etc., can solve the problems of bottle not only looking messy, product flows out, and it is difficult to control the amount of product to be dispensed from the bottl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

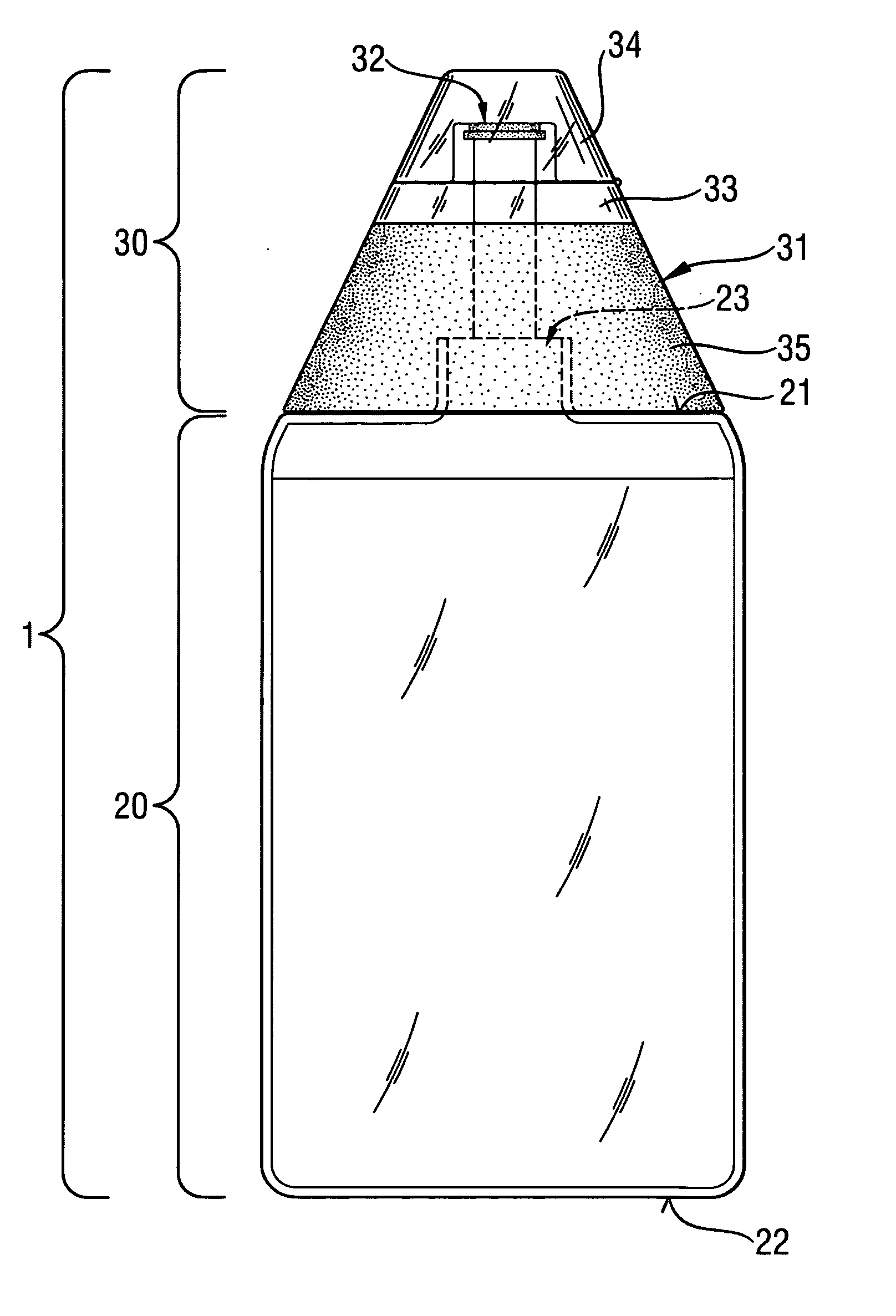

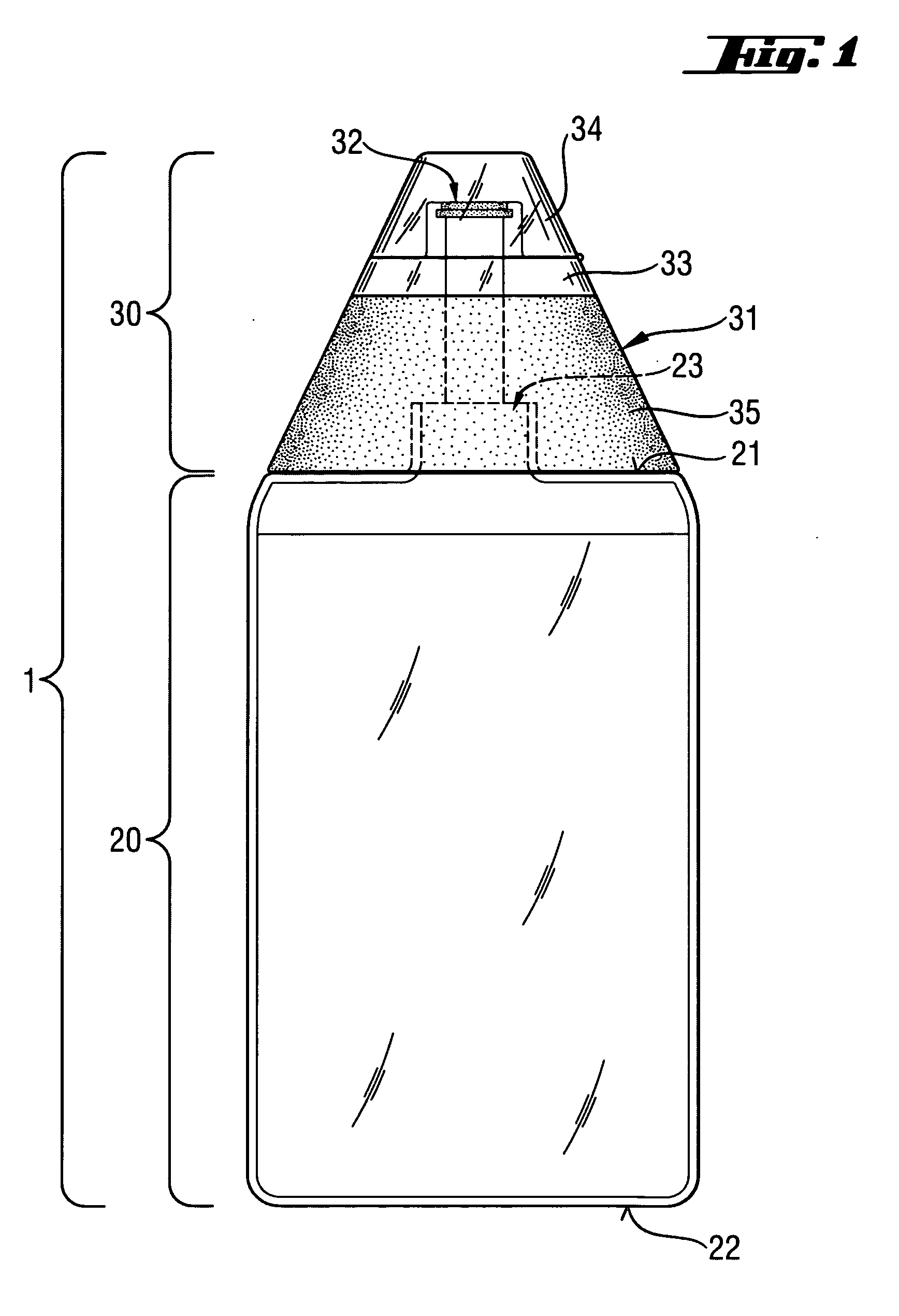

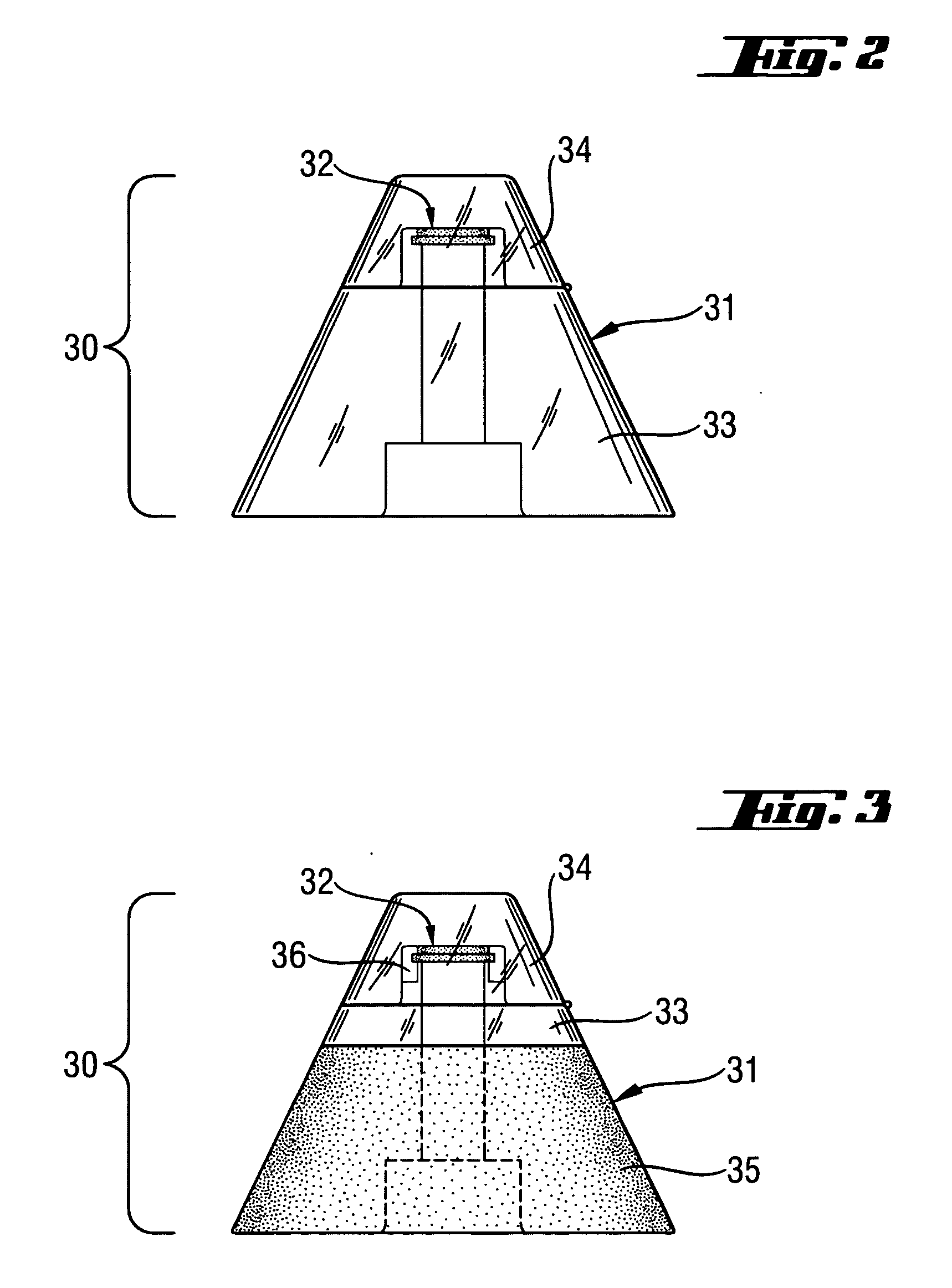

[0015] In a first embodiment, the present invention relates to a top-up container assembly (1) comprising a container (20) and a dispensing cap (30). With “top-up”, it is meant that the container assembly has a top and a bottom surface, at least a portion of said bottom surface being in contact with a horizontal flat surface when said container assembly is put on that horizontal flat surface. The top surface of the container assembly is located away from said bottom surface, and does not contact the horizontal flat surface, when the container assembly is put on that horizontal surface.

[0016] The container (20) of the present invention may be a bottle or a stand-up pouch where the container is a bottle it is preferably a squeeze-bottle having flexible walls. The container has a bottom surface (22) and a top surface (21) located away from said bottom surface (22), and an opening (23) in said top surface (21). At least a portion of said bottom surface (22) is in contact with a horizont...

fourth embodiment

[0028] In a fourth embodiment, the present invention also relates to a method of cleaning dishware, using the dishwashing cleaning product described hereinabove. The method comprises at least the steps of inverting the dishwashing cleaning product, and then squeezing the bottle (20) such that the valve (32) opens and the dishwashing cleaning composition is dispensed from the top-up container assembly (1).

[0029] The composition may be applied to the dishware neat or in dilute form. Thus the dishware may be cleaned singly by applying the composition to the dishware and optionally but preferably subsequently rinsing before drying. Alternatively, the composition can be mixed with water in a suitable vessel, for example a basin, sink or bowl and thus a number of dishes can be cleaned using the same composition and water (dishwater). In a further alternative process the product can be used in dilute form in a suitable vessel as a soaking medium for, typically extremely dirty, dishware. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com