Device for driving an output mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

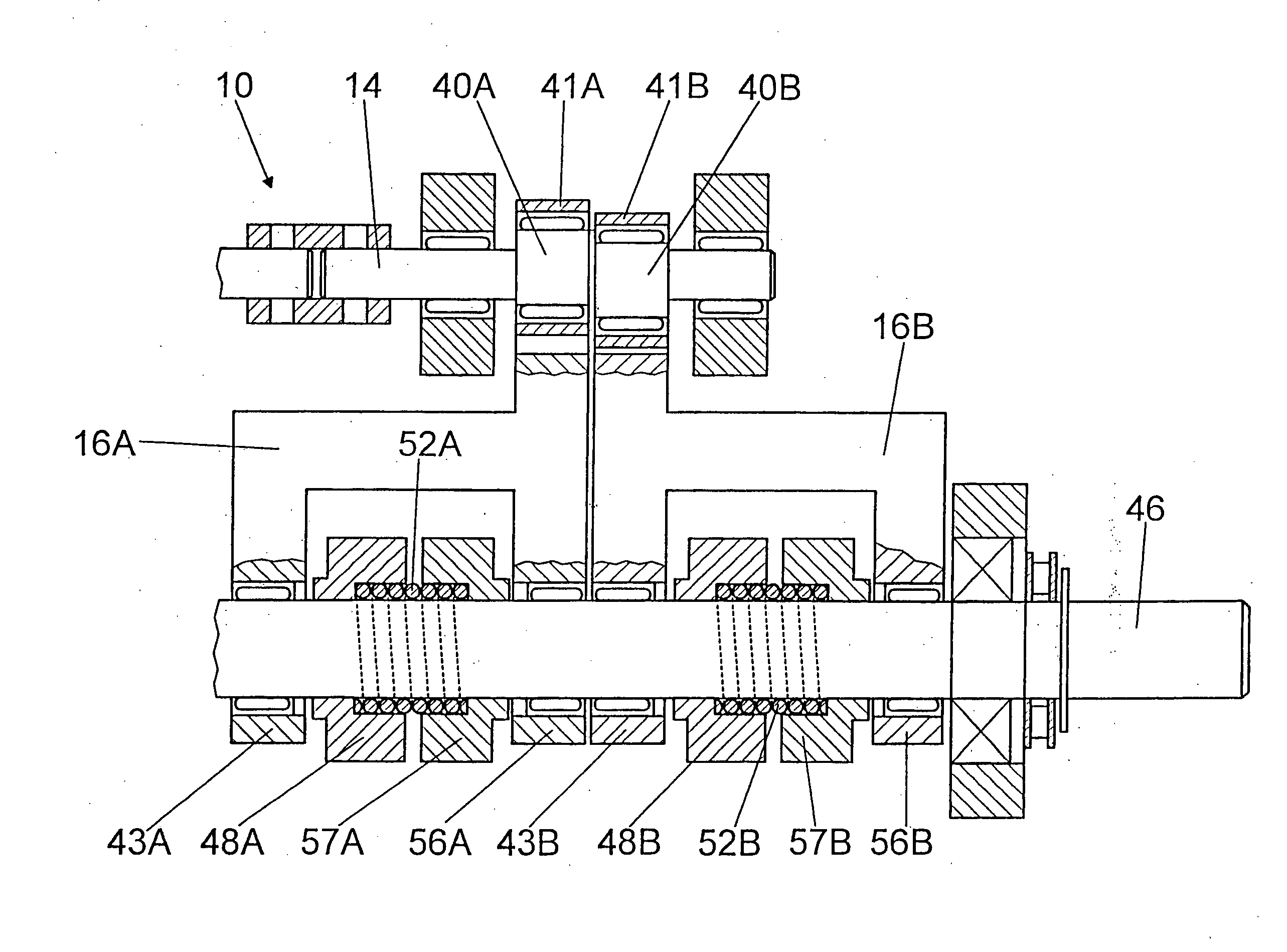

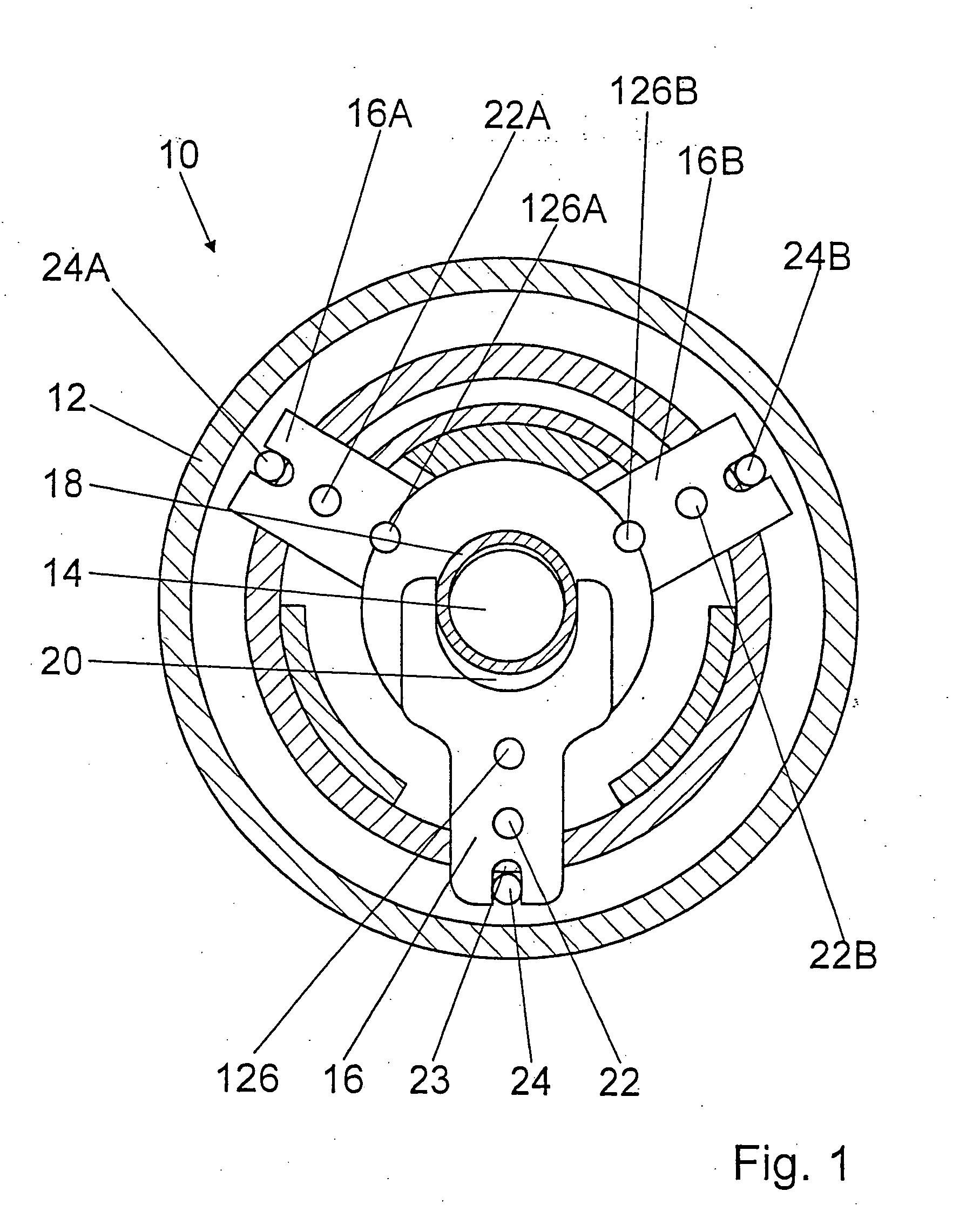

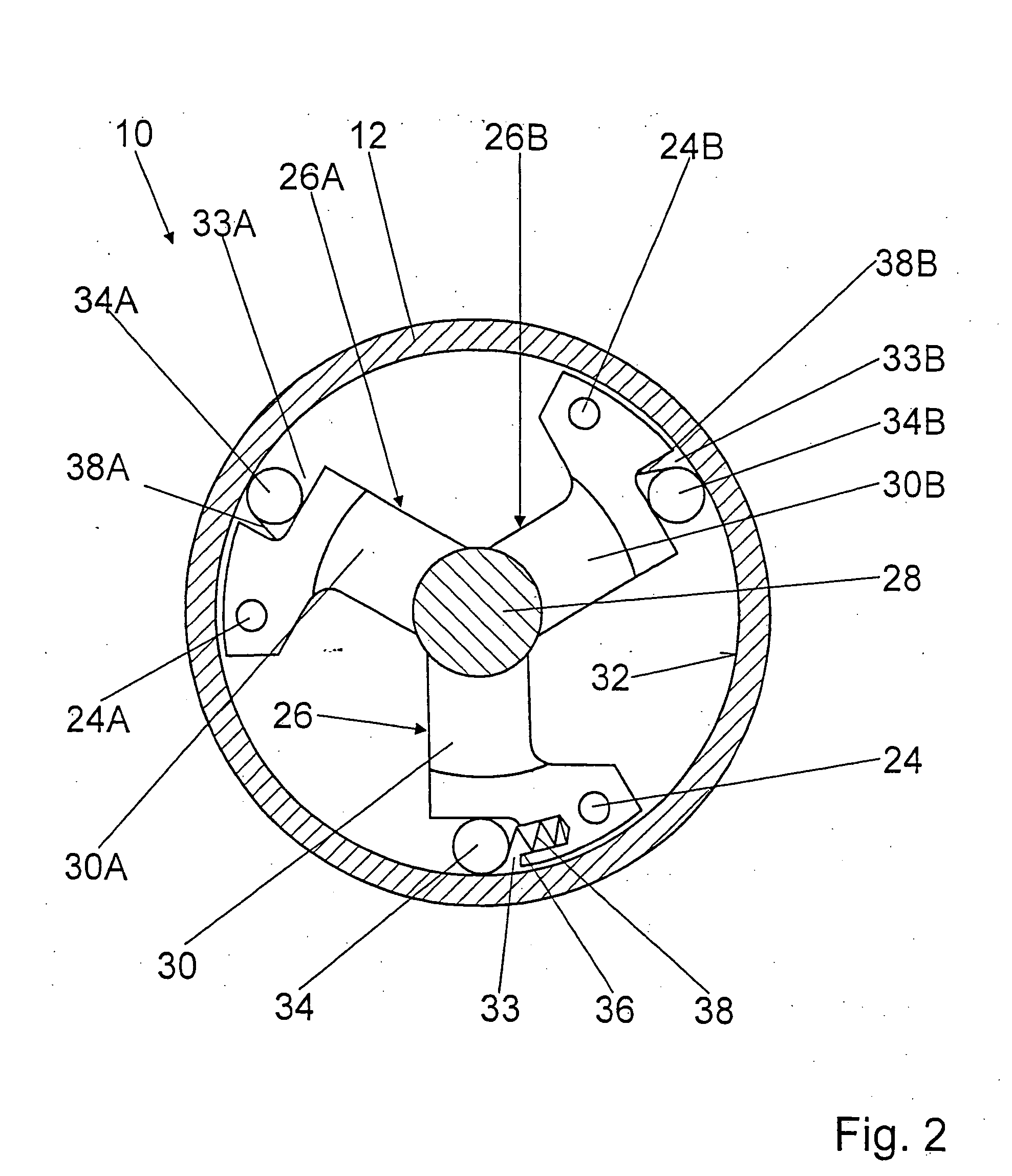

[0015]FIGS. 1 and 2 show a device 10 for driving an output mechanism via an annular body 12, comprising a rotationally driveable input shaft 14 of the device 10 that serves simultaneously as the output shaft of a not-shown electric motor. Means for transmitting a drive torque of the input shaft 14 to the output mechanism or the annular body 12 installed upstream from the output mechanism are located between the input shaft 14 and the output mechanism.

[0016] A non-positive functional connection can be created between a first means 16 configured as oscillating crank and the output mechanism, by means of which an alternating movement of the oscillating crank 16 can be converted into a plurality of successive movements or rotational movements of the output mechanism in one direction, whereby the multiple movements effect a continuous operation of the output mechanism. In addition to the first oscillating crank 16, two oscillating cranks 16A and 16B of identical design are situated at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com