Multilayer injection compression molding method using recycled material, and molded product molded through the same

a technology of injection compression molding and recycled material, which is applied in the direction of synthetic resin layered products, manufacturing tools, transportation and packaging, etc., can solve the problems of insufficient appearance and mechanical strength of parts of molded products of 100% recycled thermoplastic resin, low use rate of recycled thermoplastic resin through those recycling methods, and high cost of molded products. , to achieve the effect of improving the use rate of recycled thermoplastic resin material, improving the appearance and appearance, and improving the use rate of recycled thermoplastic resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

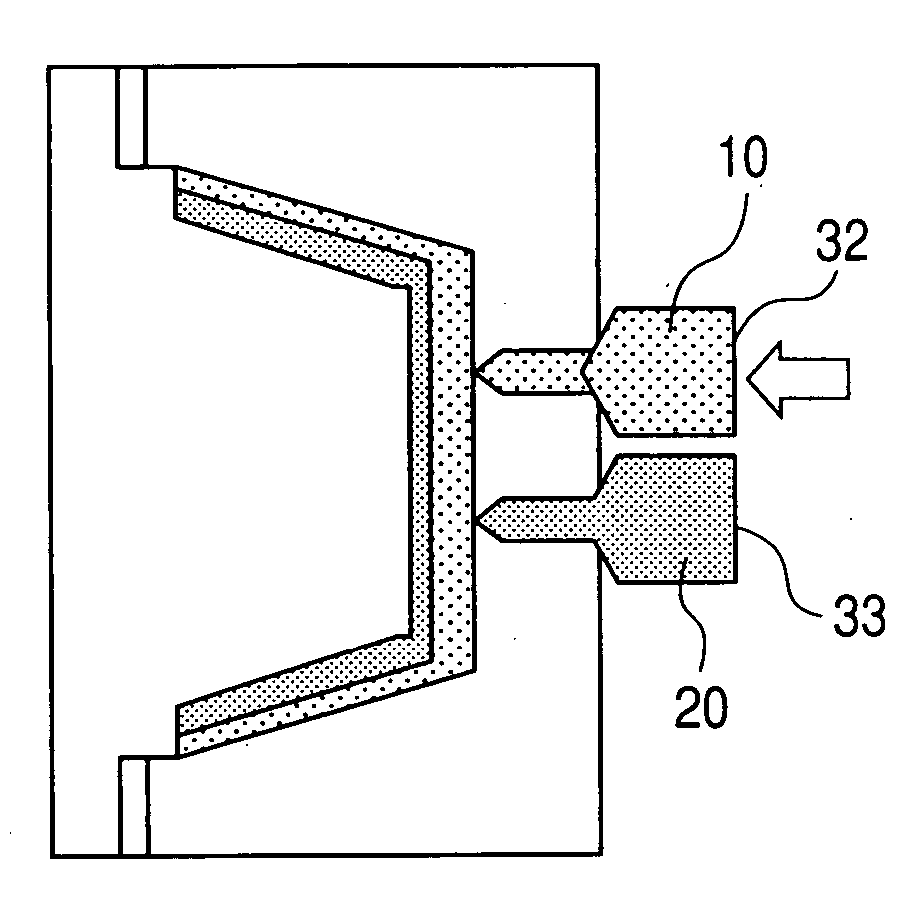

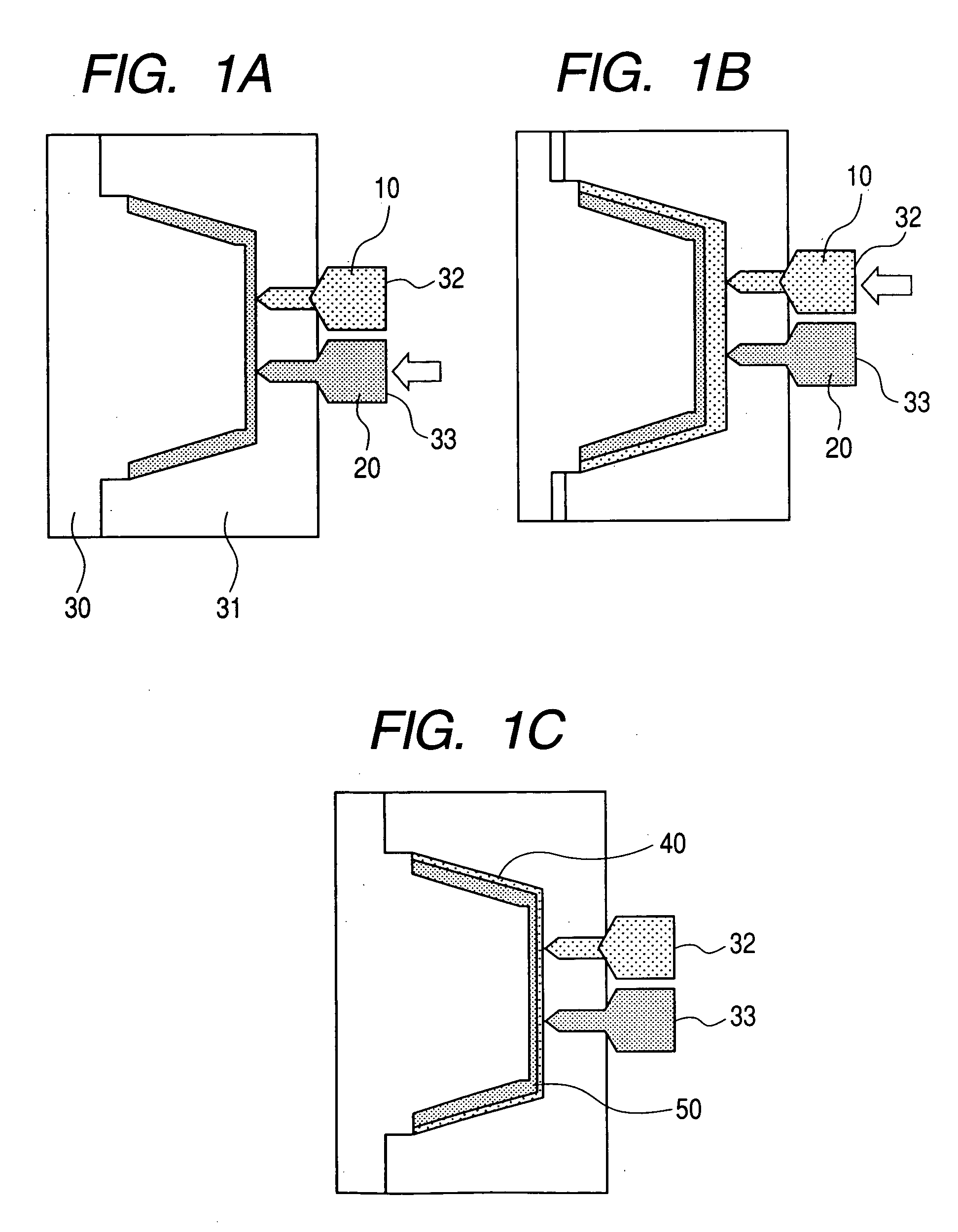

[0035] A recycled thermoplastic resin 20 is injected from an injection cylinder 33 into a mold including a movable mold 30, a stationary mold 31, and inserts thereof while the mold is closed and a mold closing force is maintained. A molten resin is cooled and solidified while a dwell pressure is applied thereto, to thereby form a first layer (FIG. 1A). Note that the first layer need not be completely solidified.

[0036] Next, the movable mold 30 is moved back for several mm and stopped, and an unused thermoplastic resin 10 is injected from an injection cylinder 32 into a newly formed space between the stationary mold and the first layer (FIG. 2B). At this time, an amount of the resin need not be equal to an amount required for completely filling the space, and a predetermined amount thereof is injected. The movable mold 30 and the stationary mold 31 each have a joint opening wider than a mold opening distance from a completely closed mold, a structure corresponding to the joint, and ...

embodiment 2

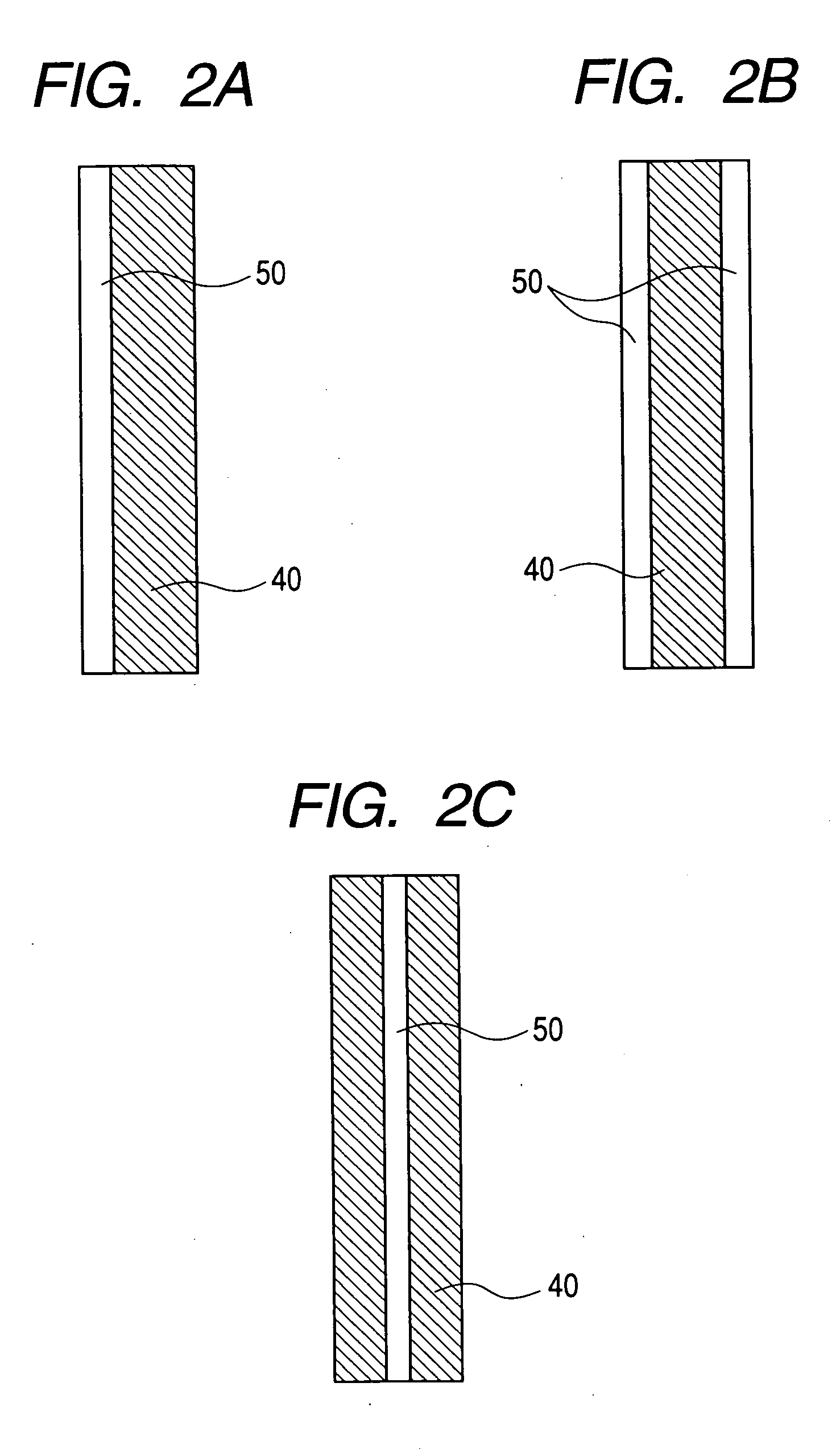

[0042] An unused thermoplastic resin 10 is injected from the injection cylinder 32 into a space between the movable mold 30 and the stationary mold 31 by using the same mold as that of Embodiment 1 with the mold opened by several mm. At this time, an amount of the resin need not be equal to an amount required for completely filling the space, and a predetermined amount thereof was injected. The movable mold 30 and the stationary mold 31 each have a joint opening wider than a mold opening distance from a completely closed mold, a structure corresponding to the joint, and a function of sealing the injected resin.

[0043] Then, the movable mold 30 is moved in a direction of the stationary mold 31 for a predetermined distance before solidification of the injected molten resin during injection or after injection, to thereby compress the molten resin injected from the injection cylinder 32.

[0044] Next, the molten resin is cooled and solidified to form a first layer.

[0045] Next, the movab...

embodiment 3

[0053] A recycled thermoplastic resin 20 is injected from the injection cylinder 33 into the same mold as that of Embodiment 1 while the mold is closed and a mold closing force is maintained. A molten resin is cooled and solidified while a dwell pressure is applied thereto, to thereby form a first layer. Note that the first layer need not be completely solidified.

[0054] Next, the movable mold 30 is moved back for several mm and stopped, and an unused thermoplastic resin 10 is injected from the injection cylinder 32 into a newly formed space between the stationary mold 31 and the first layer. At this time, an amount of the resin need not be equal to an amount required for completely filling the space, and a predetermined amount thereof is injected. The movable mold 30 and the stationary mold 31 each have a joint opening wider than a mold opening distance from a completely closed mold, a structure corresponding to the joint, and a function of sealing the injected resin.

[0055] Then, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compositions | aaaaa | aaaaa |

| physical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com