Construction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

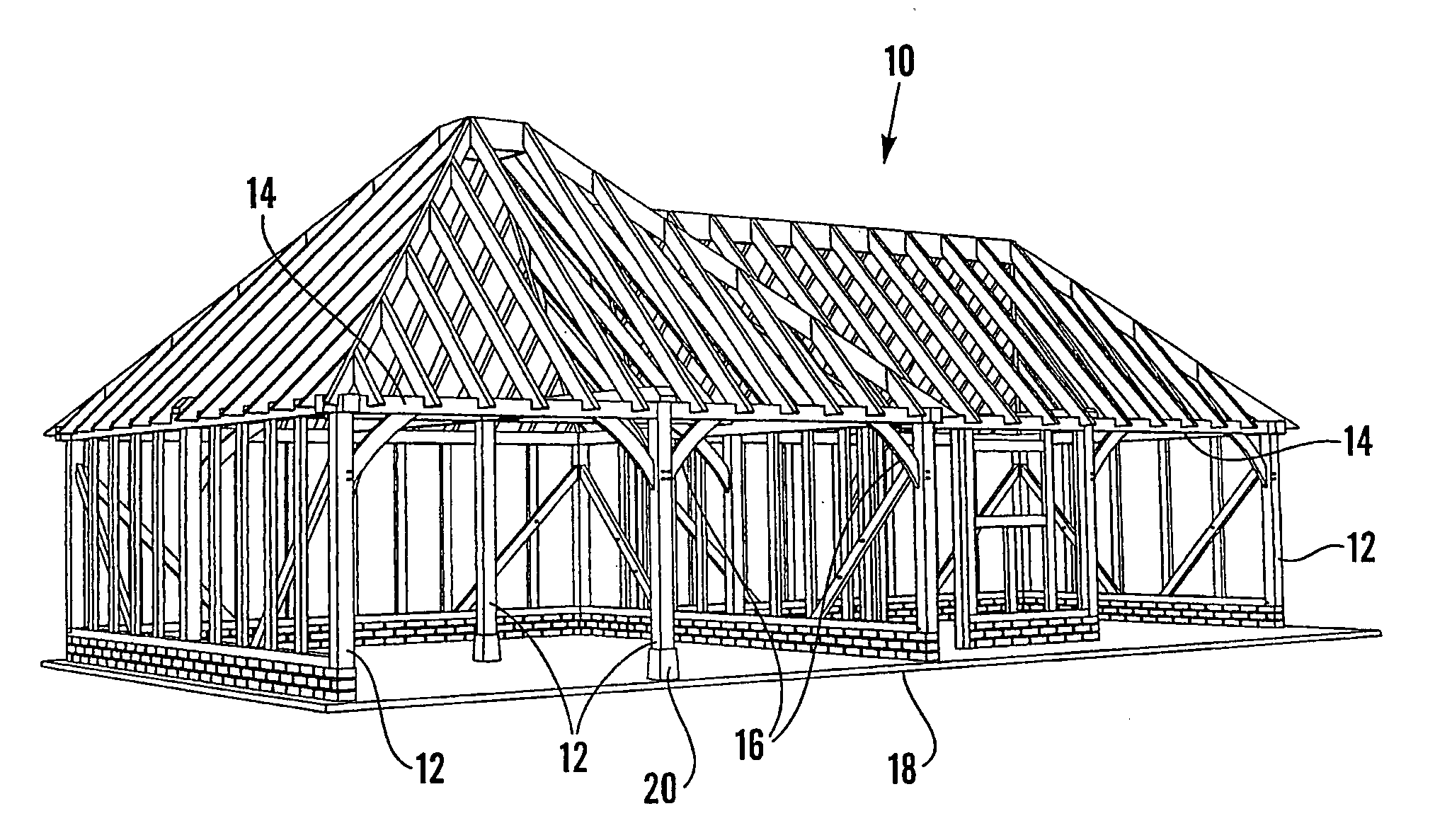

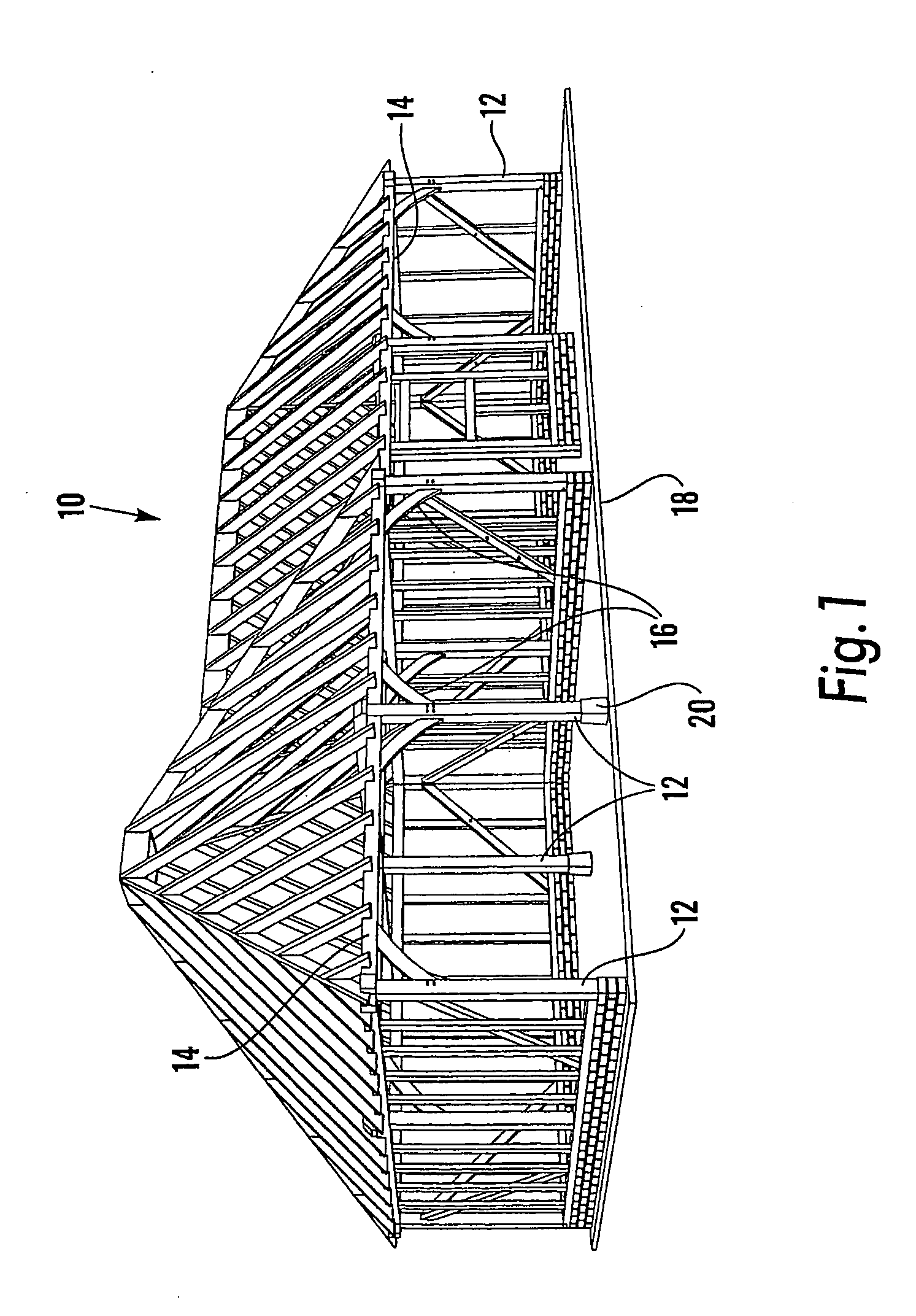

[0047]FIG. 1 shows the superstructure of a timber-framed building (10) which comprises a plurality of vertical posts (12) supporting horizontal beams (14). Braces (16) are fitted between beams (14) and posts (12) to increase stiffness and lend architectural interest. The posts (12) are fixed to the ground (18), in some cases using base plates (20) which are bolted to the foundations. The posts (12) and beams (14) are coupled together by coupling parts (30,50) connected by locking pins (70) concealed from view by the posts and beams themselves.

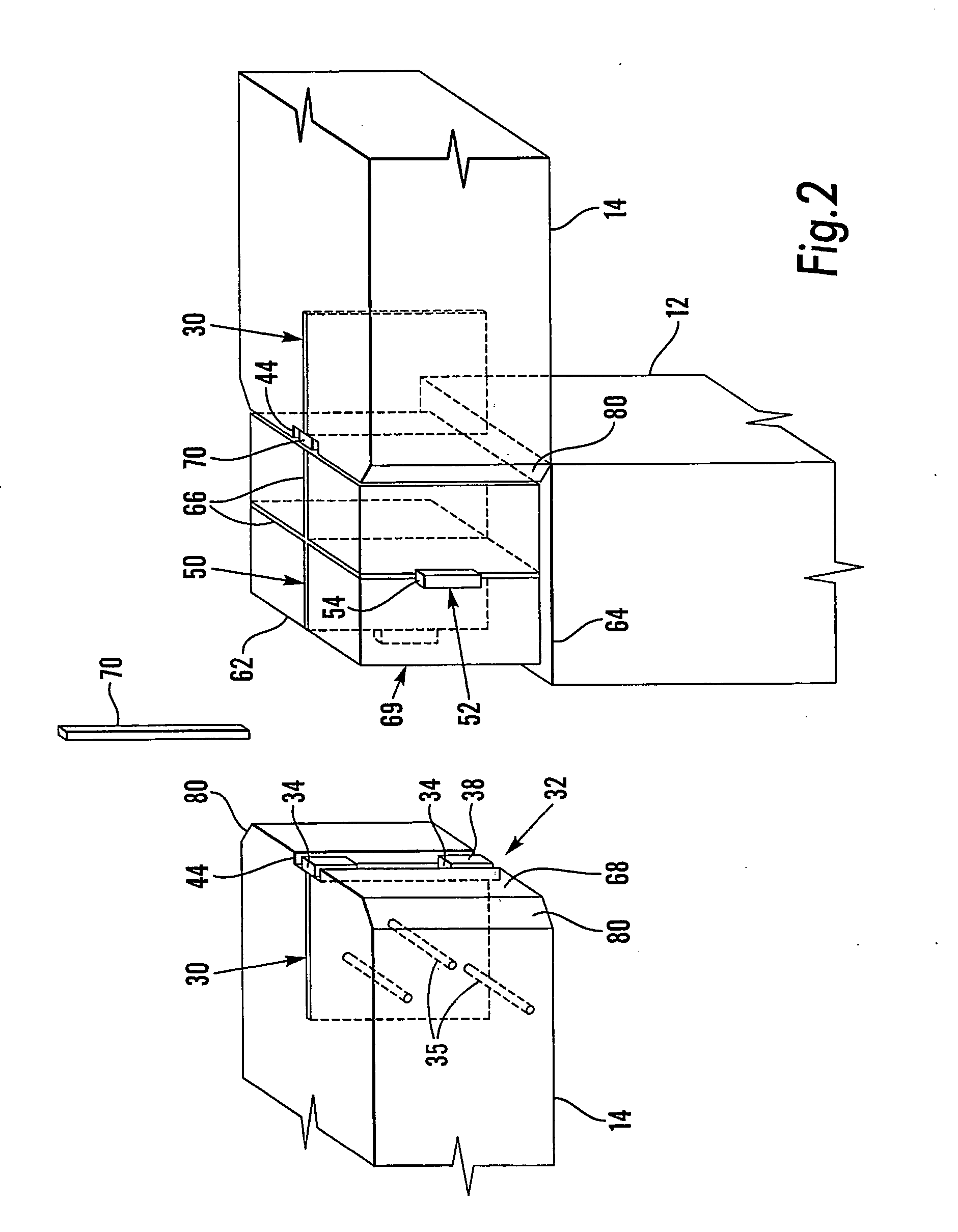

[0048]FIG. 2 shows in detail how a beam (14) is coupled to a post (12) in accordance with the present invention. A first coupling part (30) is attached to one end of a beam (14), and a second coupling part (50) is attached to the post (12). The coupling parts (30,50) have end profiles (32,52) with apertures (34,54) which are registrable. Once registered, the apertures are slidably engaged by a locking pin (70), coupling the beam to the post. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com