Floating water mat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

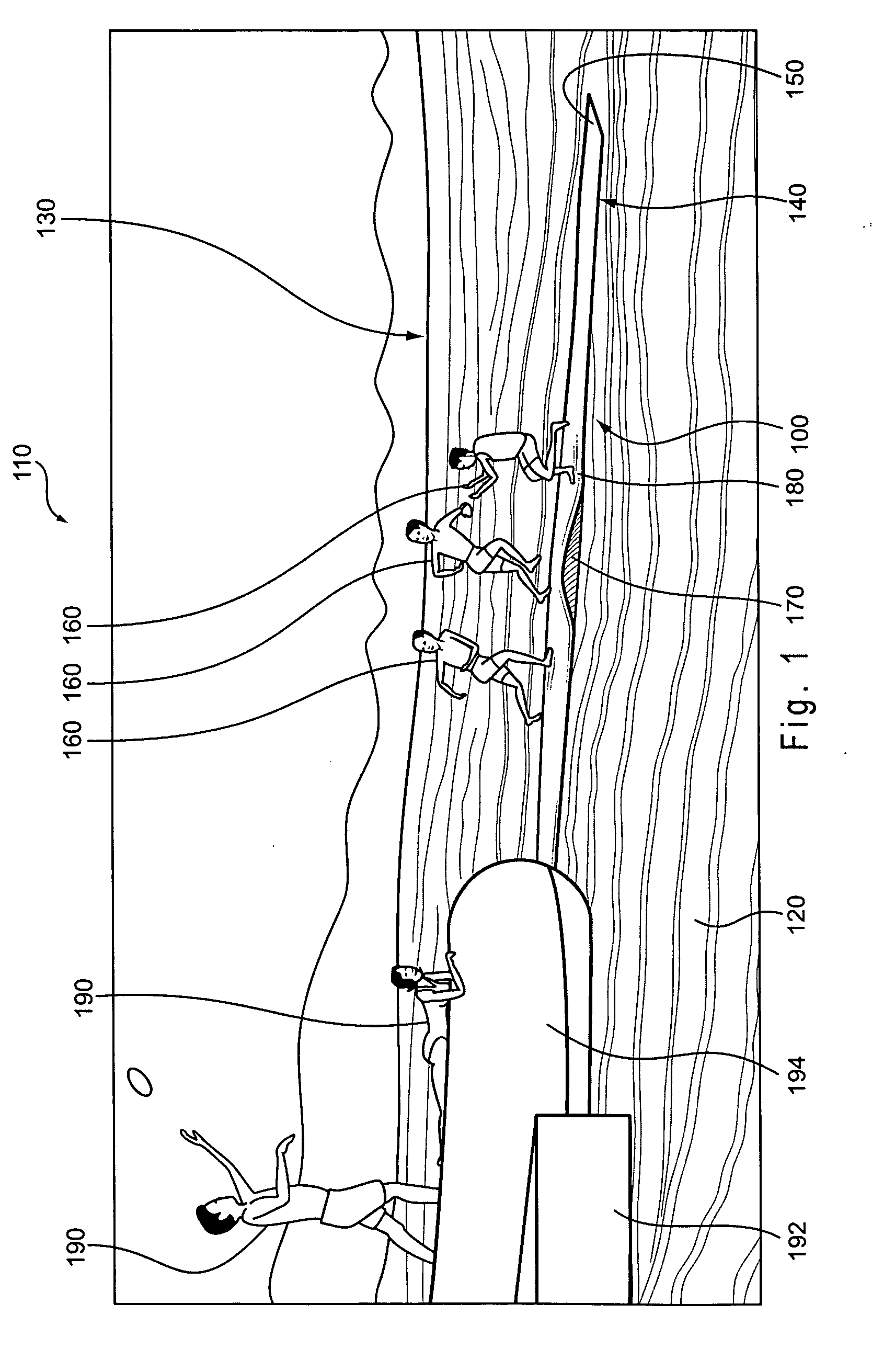

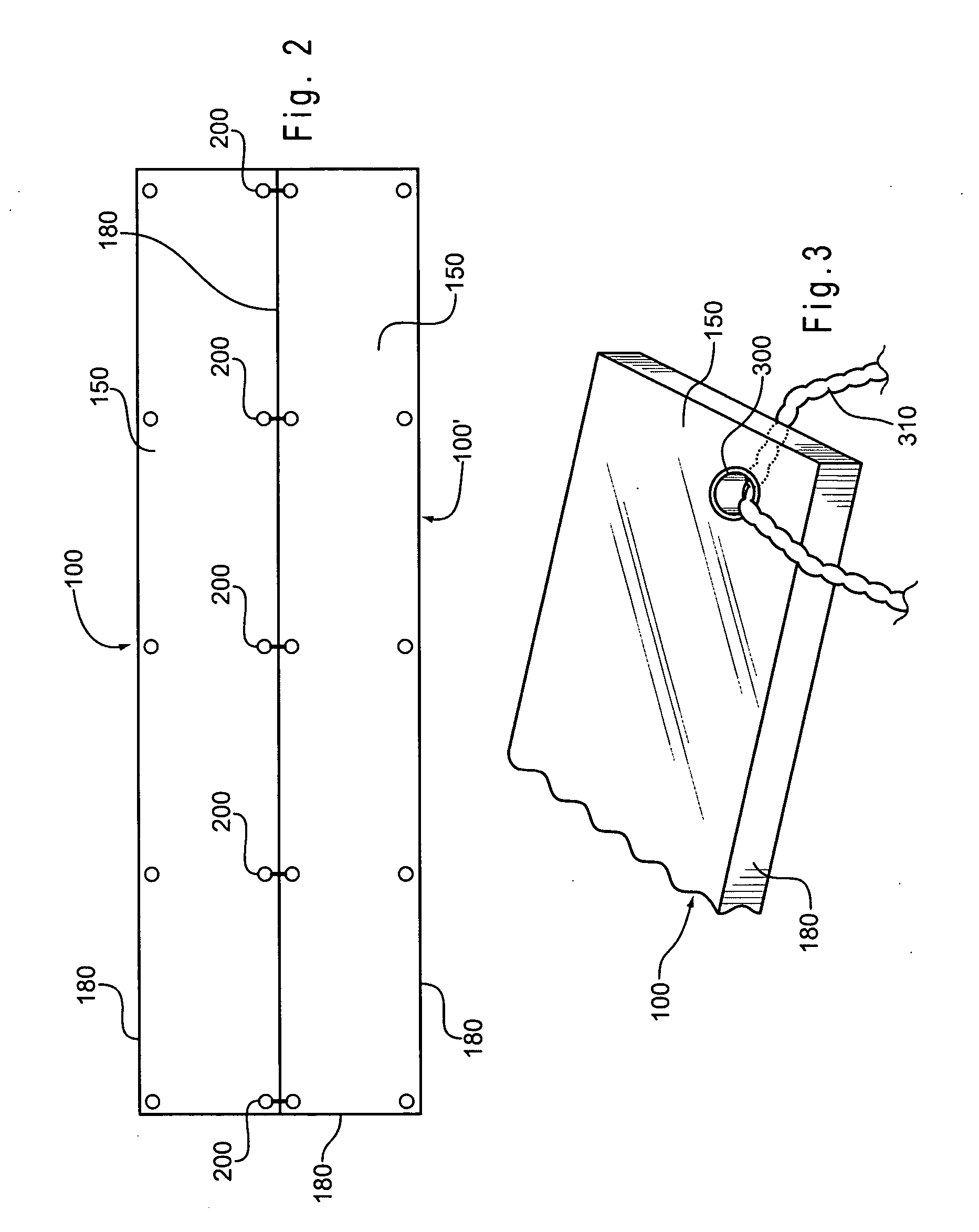

[0014]FIG. 1 is a diagram of a mat 100 in a playing environment 110. The playing environment 110 may include a body of water 120 such as a lake. The mat 100 may also be used on land 130, for example, as a water slide or gymnastic mat. The mat 100 includes a buoyant core 140. The buoyant core 140 may include a floatable foam, such as a polyurethane foam. The buoyant core 140 may include other materials such as polyethylene. The buoyant core 140 is non-inflatable. A thickness of the buoyant core 140 includes about a ¾ to about 2 inches. A gymnastics or cheerleading mat may be suitable for the buoyant core 140.

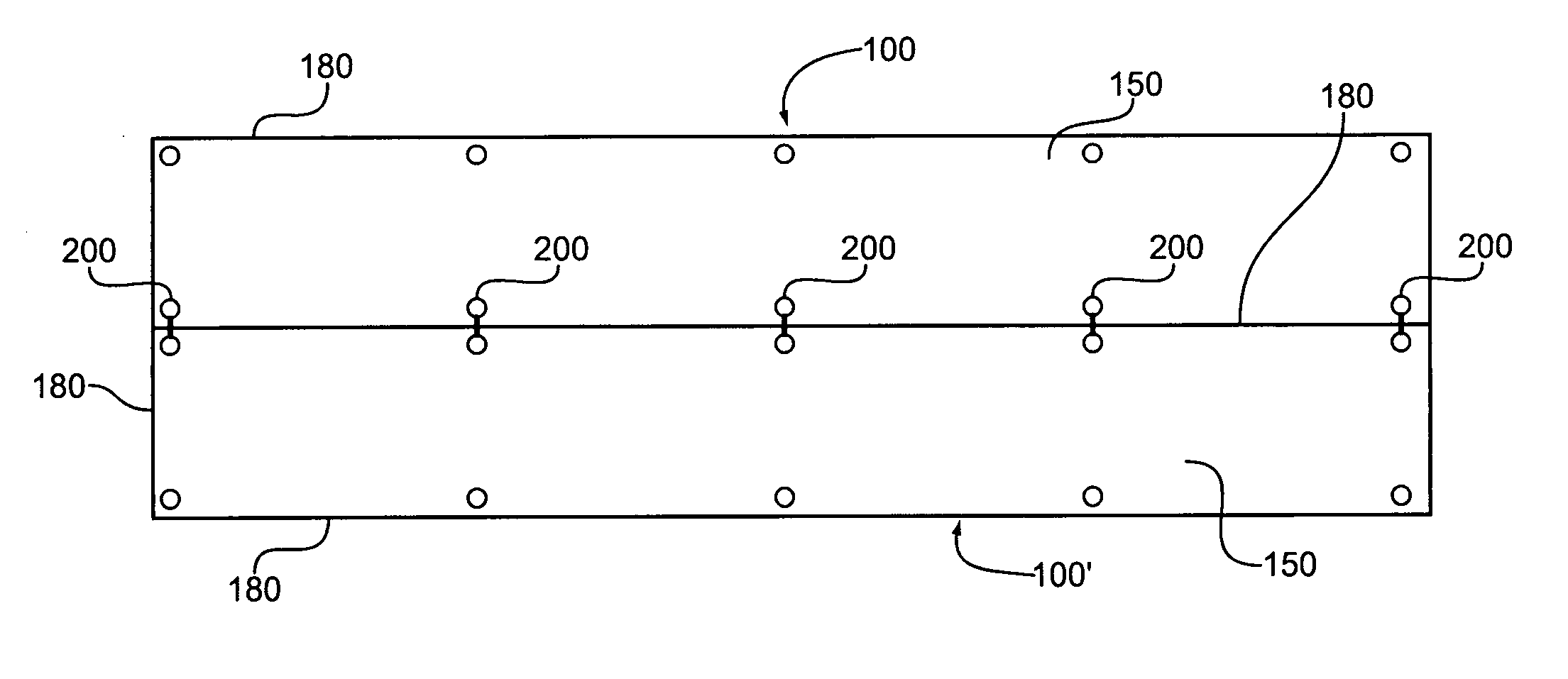

[0015] The mat 100 may be constructed of one layer or multiple layers. A top 150 of the mat 100 may by manufactured of the same material as the buoyant core 140 or other materials such as a polyurethane, to give a soft feel to a user 160. A bottom 170 and the sides 180 of the mat 100 may be constructed from the same material as the buoyant core 140 and may include other material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com