One person drywall machine

a drywall machine and one person technology, applied in the field of drywall panel installation machines, can solve the problems of requiring additional equipment and/or personel, and achieve the effects of low weight, affordable purchase and use, and low manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

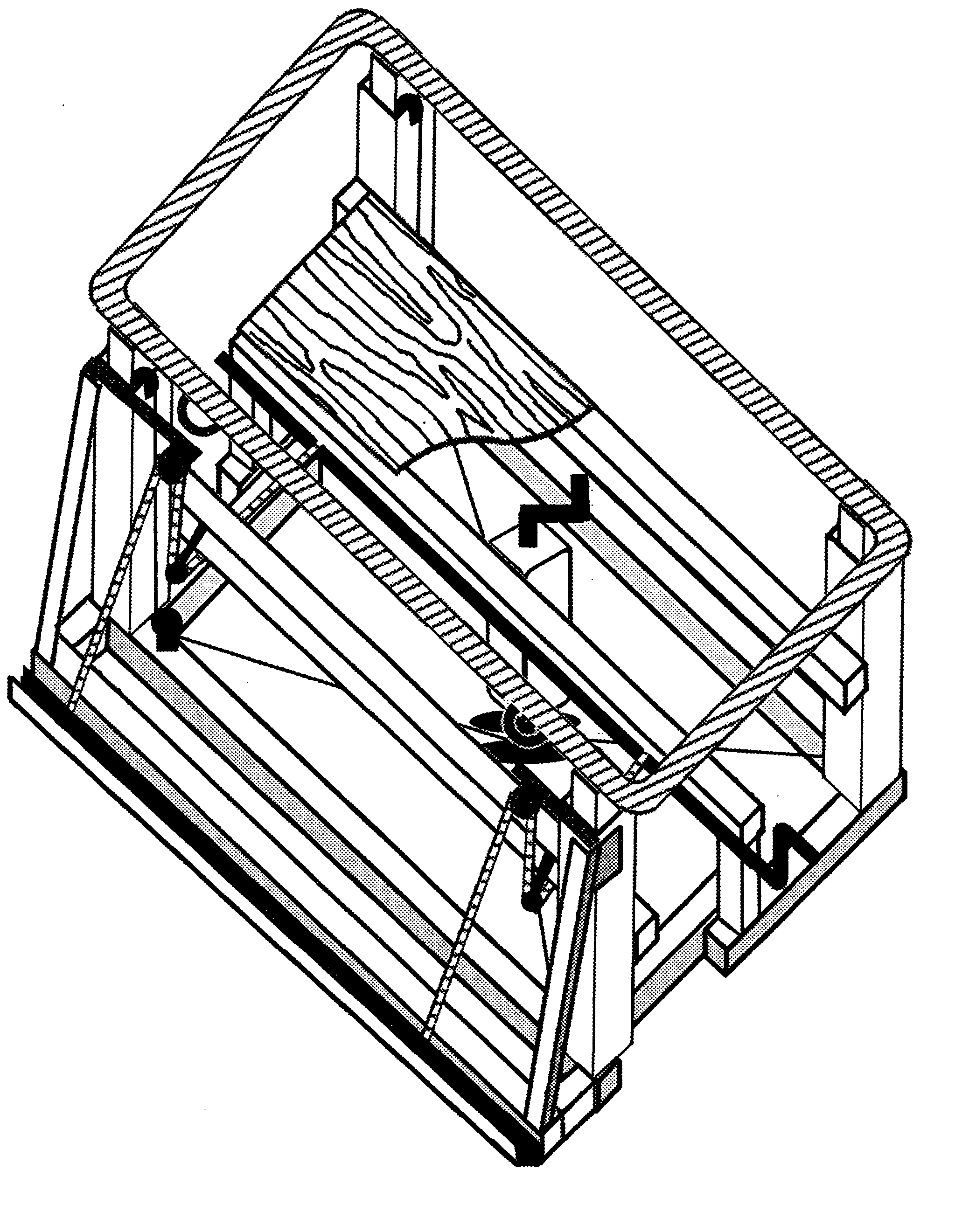

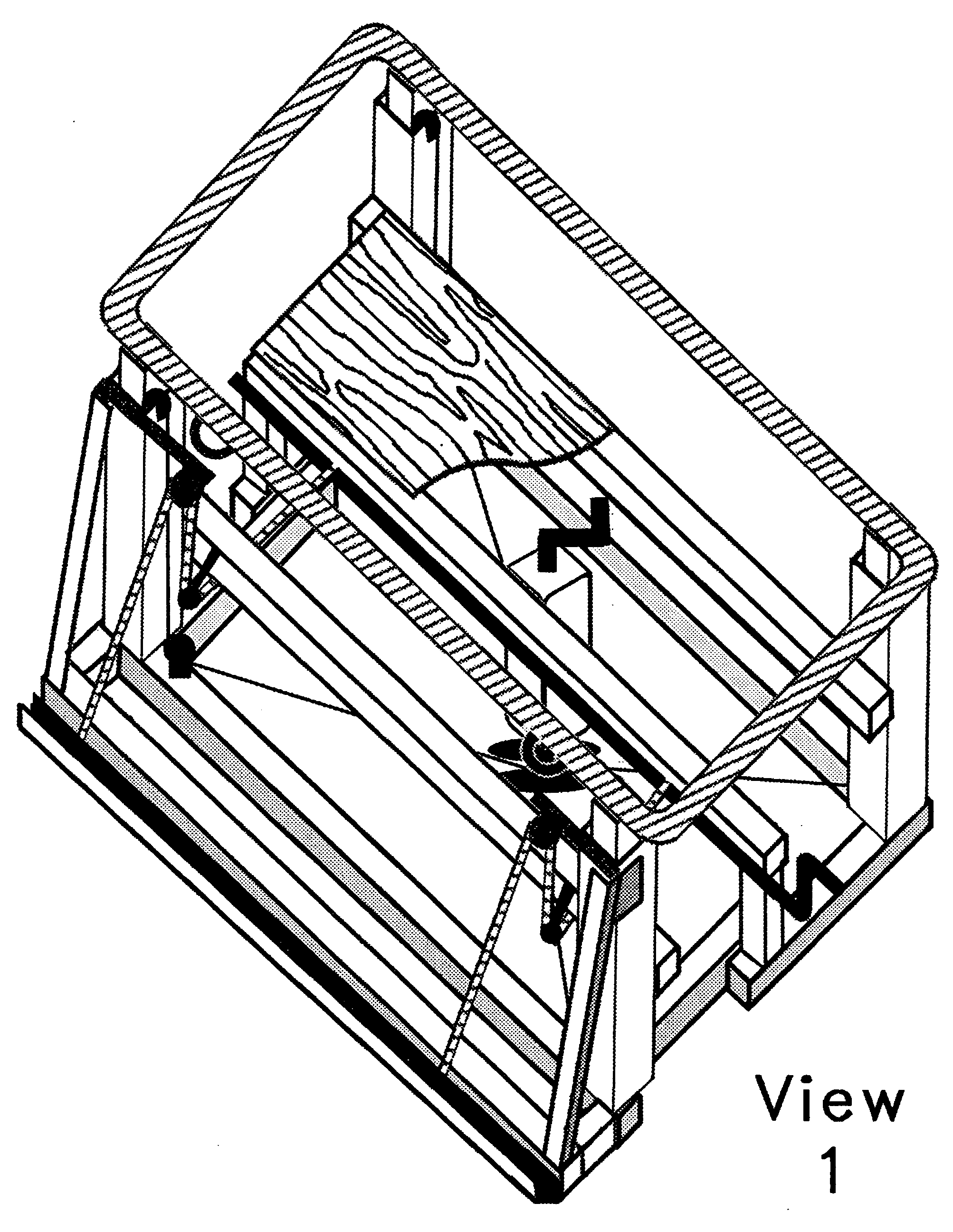

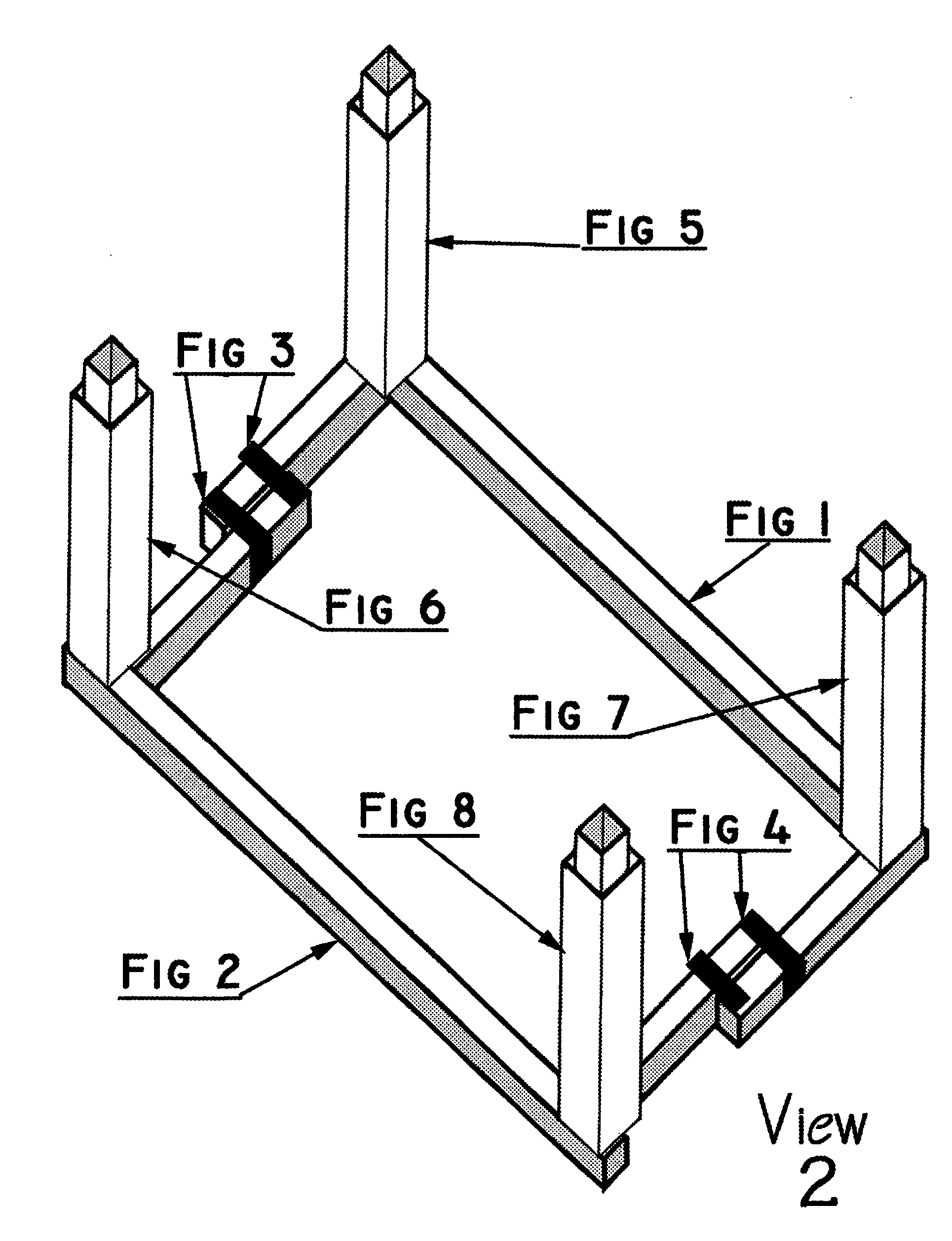

[0064] The “One Person Drywall Machine” construction consists of a generally rectangular “Frame Base” of hollow steel tubing approximately 3 ft. by 4 ft. Consisting of a “Rear Bottom Frame Section” (See View 2—FIG. 1), a “Front Bottom Frame Section” (See View 2—FIG. 2), a “Left Frame Expansion Joint” (See View 2—FIG. 3), and a “Right Frame Expansion Joint” (See View 2—FIG. 4), so constructed as to be easily contracted to approximately 2 ft. by 4 ft. (See View 2—FIG. 3 and FIG. 4, and View 6—FIG. 3 and FIG. 4) so as to provide easy access through doorways. Said “Frame Base” is mounted on common casters (not shown) at each corner to facilitate mobility of machine. Attached to the top of each corner of this frame is a “Telescoping Post” extending vertically. These posts consist of two or more sections of hollow steel tubing, one inside the other, (See View 2—FIG. 5, FIG. 6, FIG. 7, and FIG. 8 and View 7 Details of post), to allow vertical extension to ceiling height. Vertical extension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com