Continuous laundry cleaning appliance

a continuous laundry and washing machine technology, applied in the field of home laundry systems, can solve the problems of large commercial continuous laundry appliances, not adaptable to home use, and prior art machines are not typically used for clothing or garments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

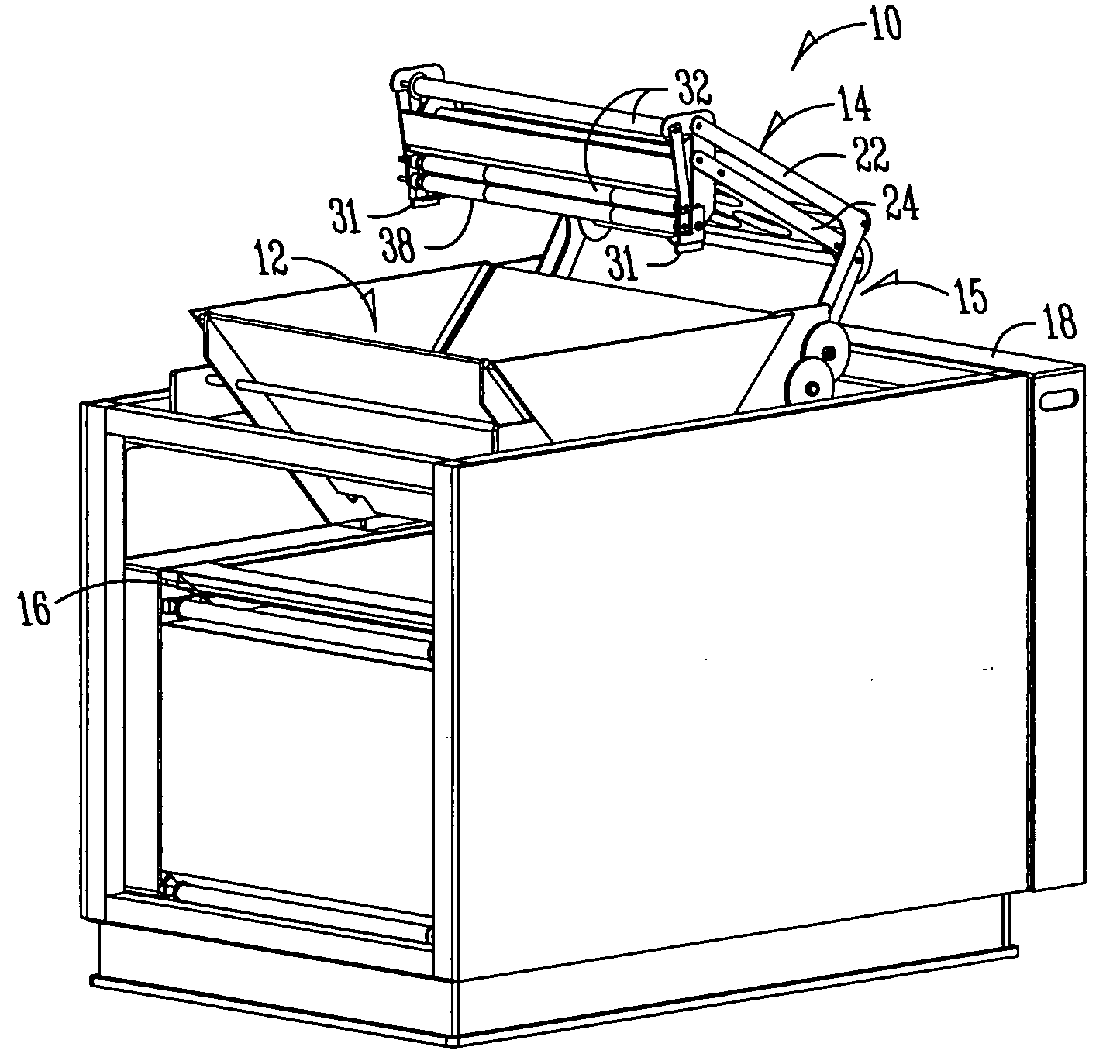

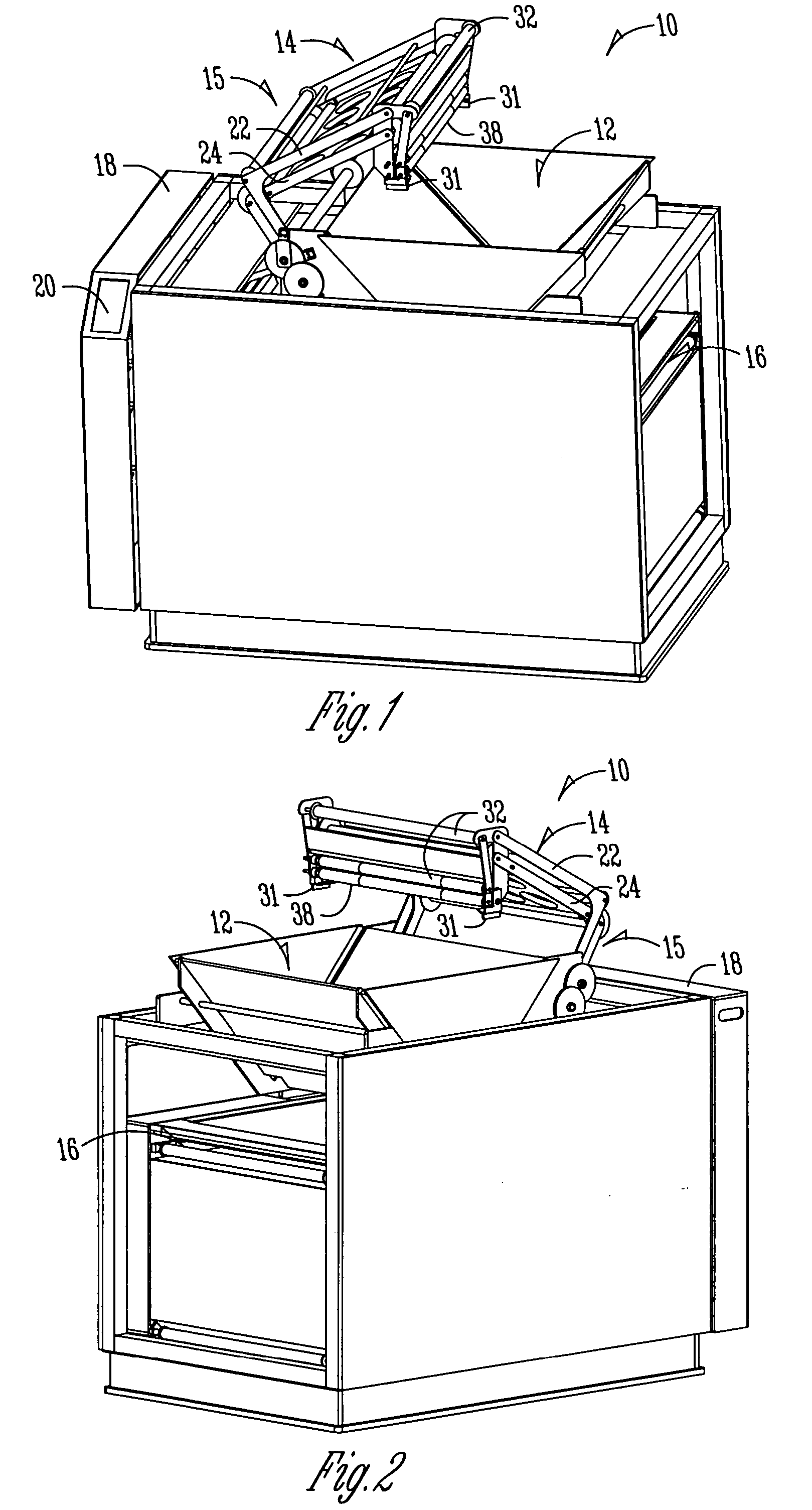

[0043] The continuous laundry cleaning appliance of the present invention is generally designated in the drawings by the reference numeral 10. The appliance 10 includes a laundry bin 12 for holding laundry. The appliance 10 also includes a feeder mechanism 14 which is mounted for reciprocal movement between a raised position above the bin 12, as seen in FIGS. 1-6 and 8, and a lowered position within the bin, as shown in FIG. 7. The appliance 10 includes one or more internal washing stations and a drying station which terminates in an outlet 16 wherein the cleaned and dried garments are discharged, as discussed in more detail below. A control module 18 with a user interface 20 allows the user to select the desired operations of the appliance 10. The control module includes a microprocessor and software for controlling operation of the appliance 10.

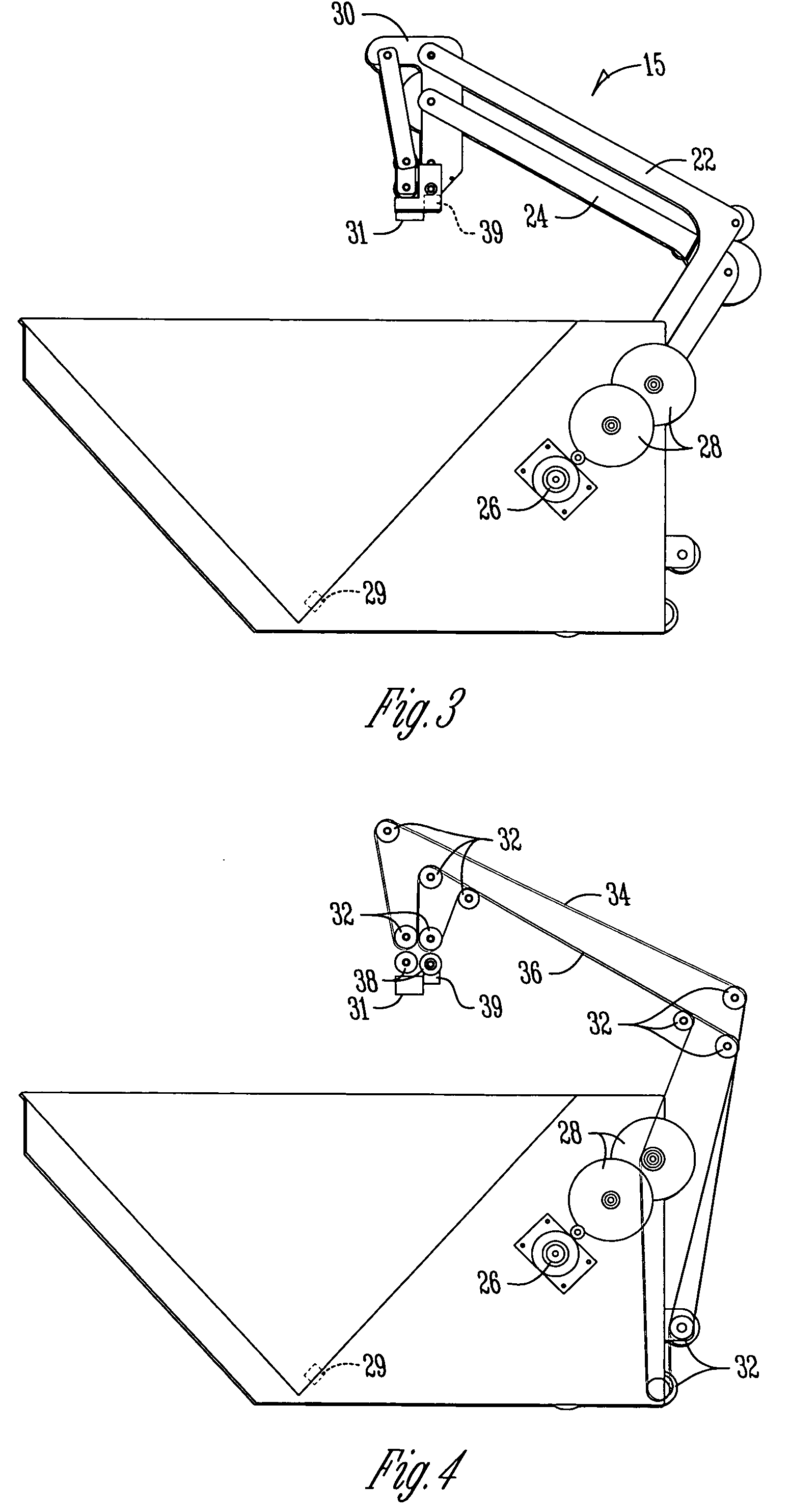

[0044] The feeder mechanism 14 includes a robotic arm assembly 15 having opposite pairs of upper and lower arms 22, 24. As shown in FIGS....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com