Process of making decorative flooring materials and decorative flooring material made by the process

a technology of decorative flooring and process, which is applied in the direction of covering/lining, constructions, and construction elements, can solve the problems that the decorative sheet does not easily peel off the base material, and achieve the effects of long life good appearance of the decorative flooring material, and soft appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] By referring to the drawing, a preferred embodiment of the present invention will be described below.

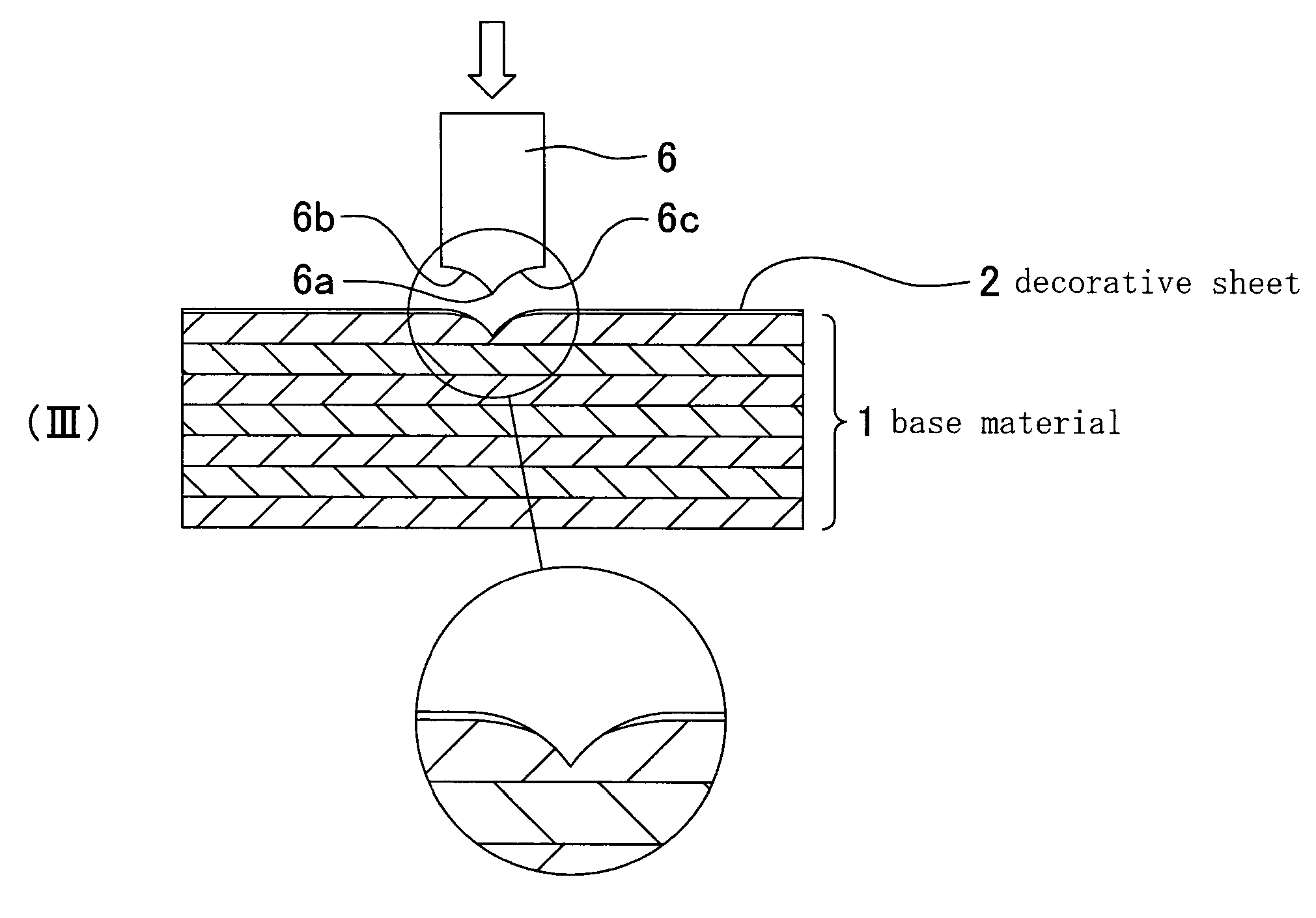

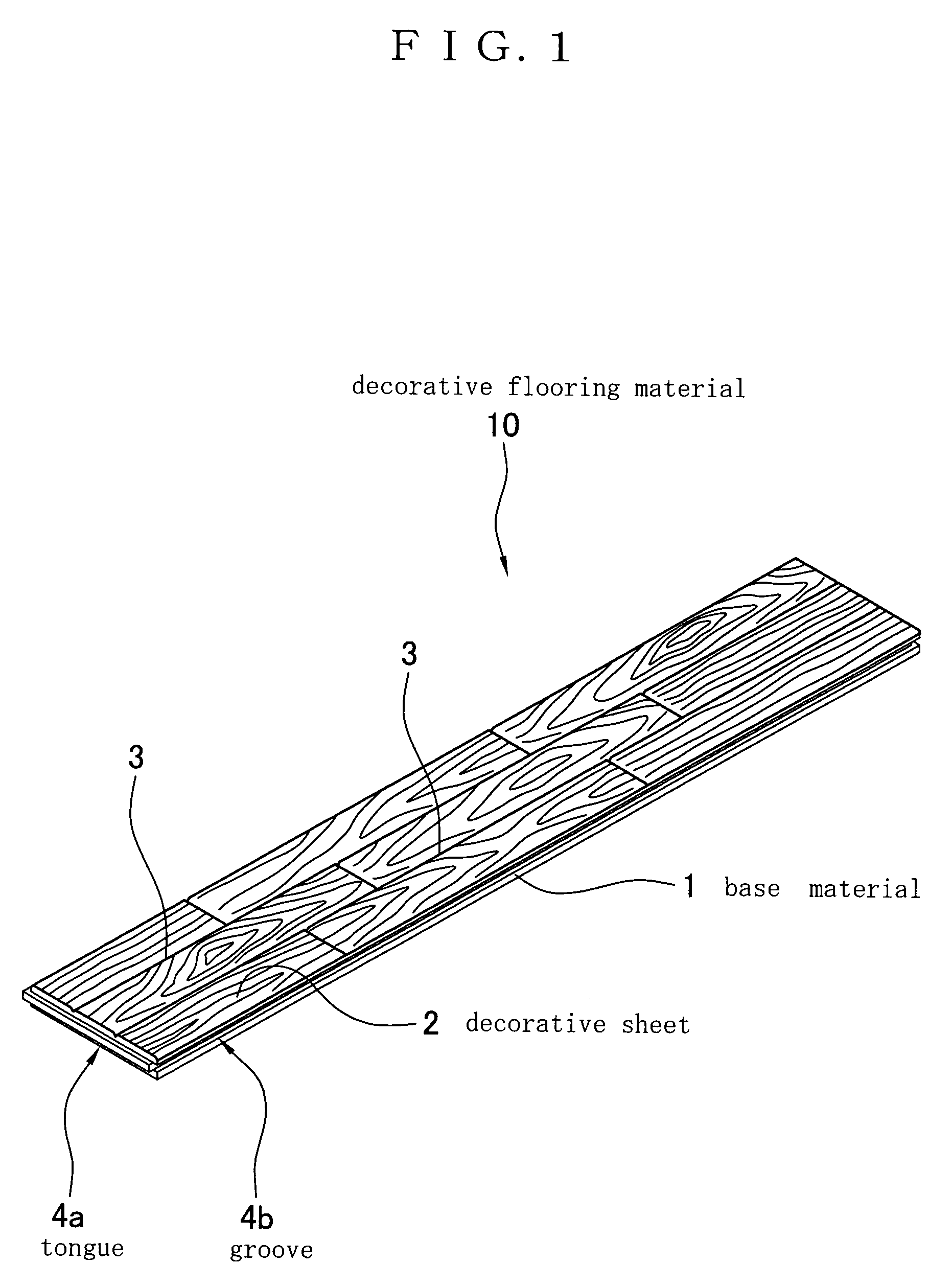

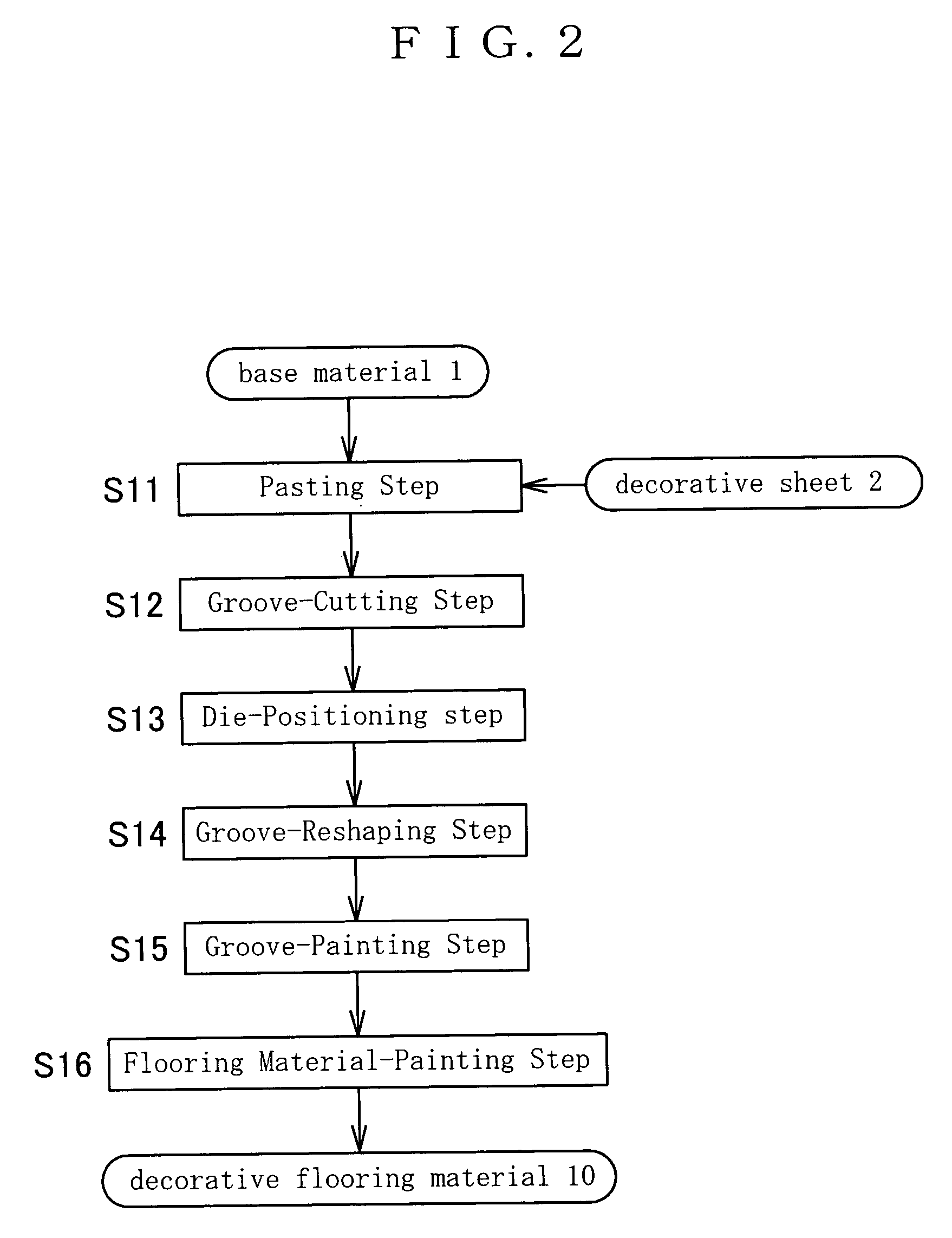

[0028]FIG. 1 is a perspective view of a decorative flooring material 10 made by a process of making decorative flooring materials according to the present invention; FIG. 2, a flowchart of the process of making the decorative flooring material 10. FIG. 3 (I) is a cross sectional view of the decorative flooring material 10 before temporary V-shaped grooves are made in its surface; FIG. 3 (II), an illustration of the construction of the decorative flooring material 10 after temporary V-shaped grooves are made in its surface. FIG. 4 (III) is an illustration of the construction of the decorative flooring material 10 after the temporary V-shaped grooves are reshaped. FIG. 5 (IV) is an illustration of the construction of the decorative flooring material 10 after the slopes of the reshaped grooves are painted; FIG. 5 (V), an illustration of the construction of the decorative floorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com