Wear resistant belts, and a process for their manufacture

a technology of wear resistance and belts, applied in the direction of driving belts, v-belts, closed loop articles, etc., can solve the problems of crack generation and tooth loss, modification alone, not completely satisfactory in some particularly demanding applications, dimensional changes, etc., to improve wear resistance and dimensional stability, reduce noise generation, and reduce heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

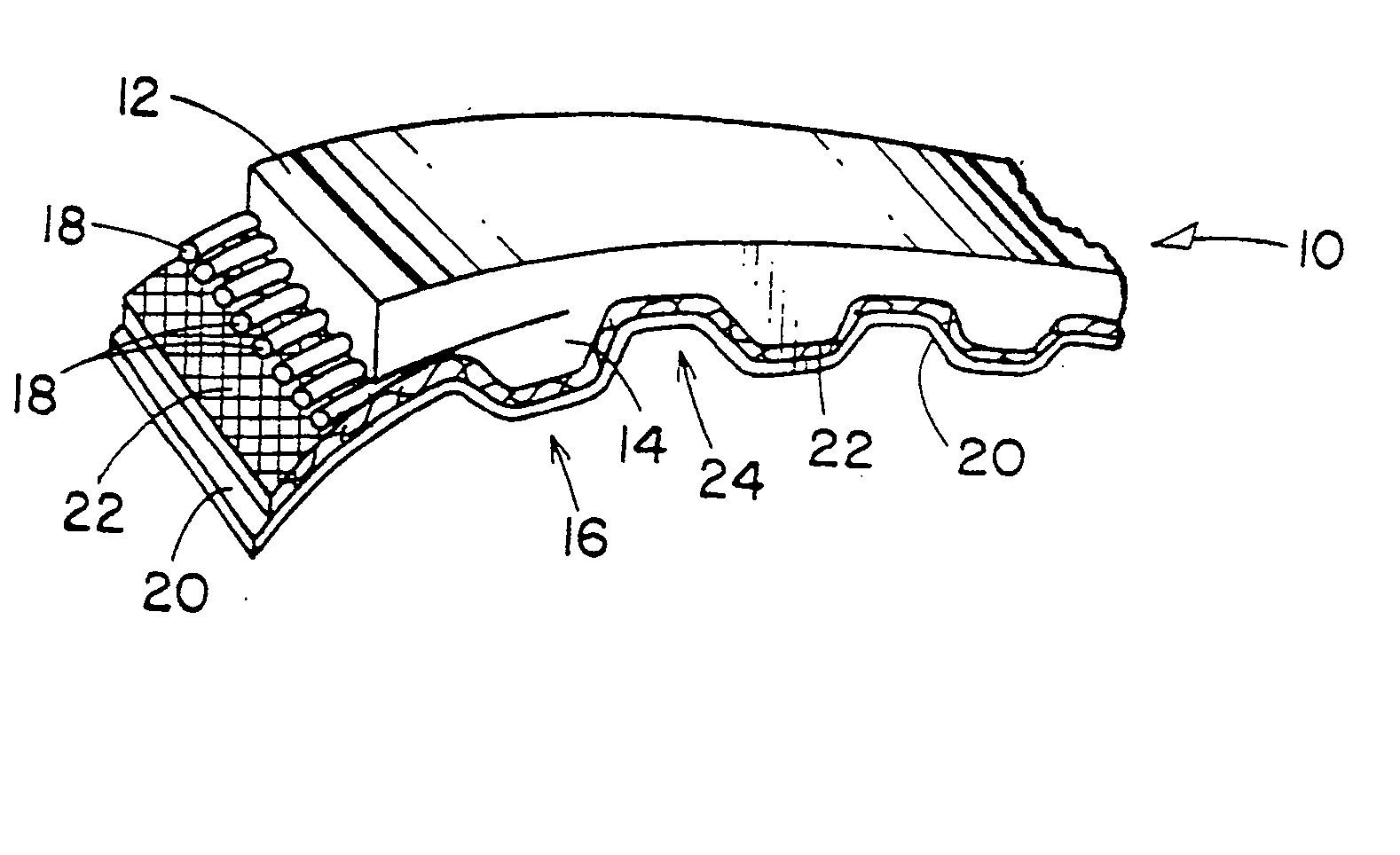

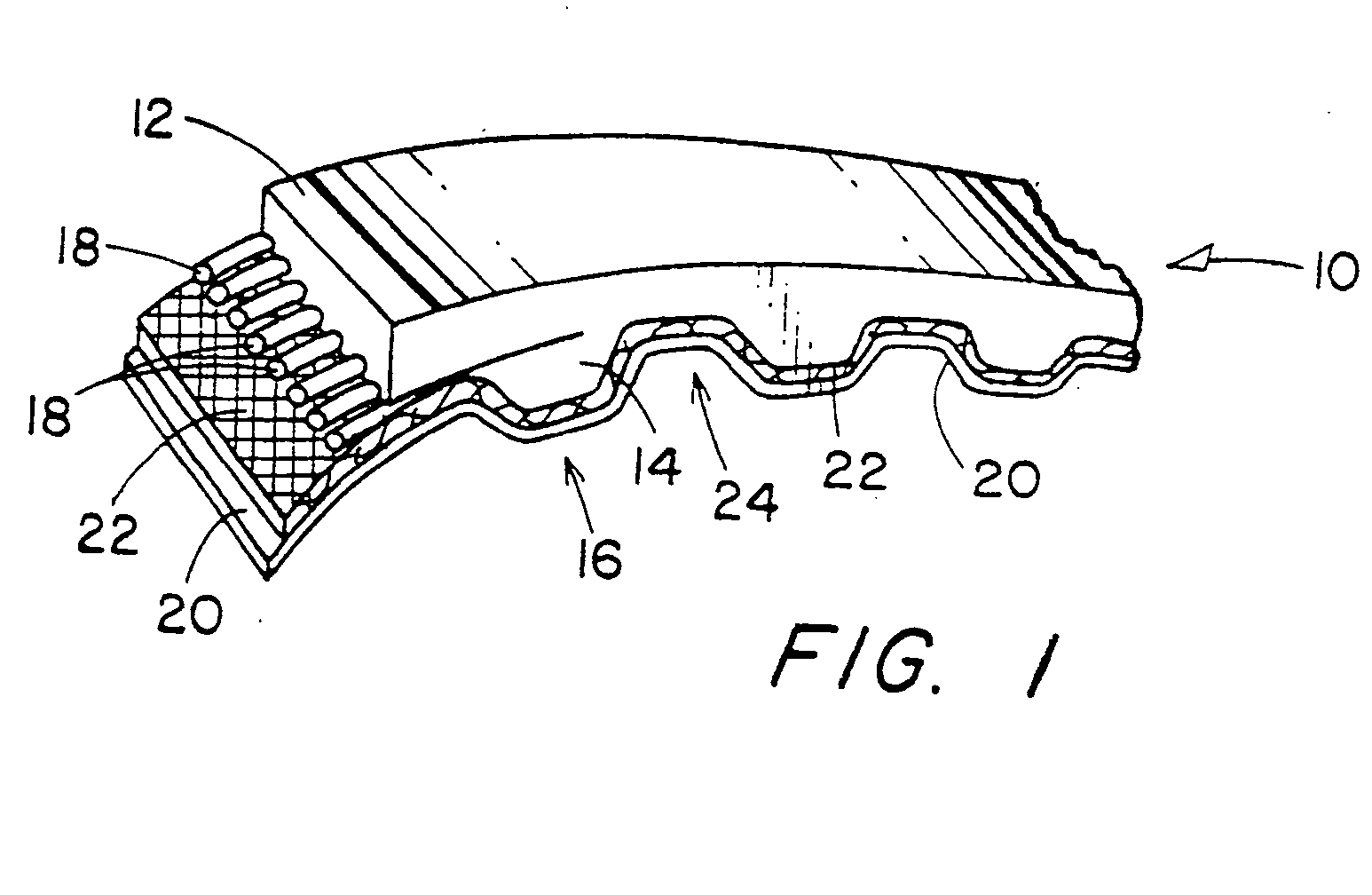

[0022] Referring to FIG. 1, an endless synchronous-type power transmission belt 10 is shown generally. The belt includes a body having an overcord section 12 formed from a suitable elastomeric material and a series of spaced cogs or teeth 16, also comprising a suitable elastomeric material 14. The elastomeric material or materials utilized in the overcord section 12 and teeth 16 should be compatible with one another and may be of the same or of different types of elastomer. Any suitable castable or non-castable elastomer may be used as the overcord or belt body elastomer, and / or the tooth portions in this embodiment of the present invention, but in a preferred embodiment at least one and preferably both of the overcord portion 12 and the teeth 16 of the belt 10 are formed of a suitable hydrogenated acrylonitrile butadiene rubber (HNBR) composition.

[0023] The elastomer overcord section 12 is preferably loaded with a reinforcing tensile layer or a plurality of tensile members, many o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Operating temperature | aaaaa | aaaaa |

| Operating temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com