Product diverter and method

a diverter and product technology, applied in the direction of transportation and packaging, conveyor parts, packaging, etc., can solve the problems of inability to produce packaging formats that require more products in width, limited wrappers, and equipment installation and maintenance costs, and achieve the effect of less width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

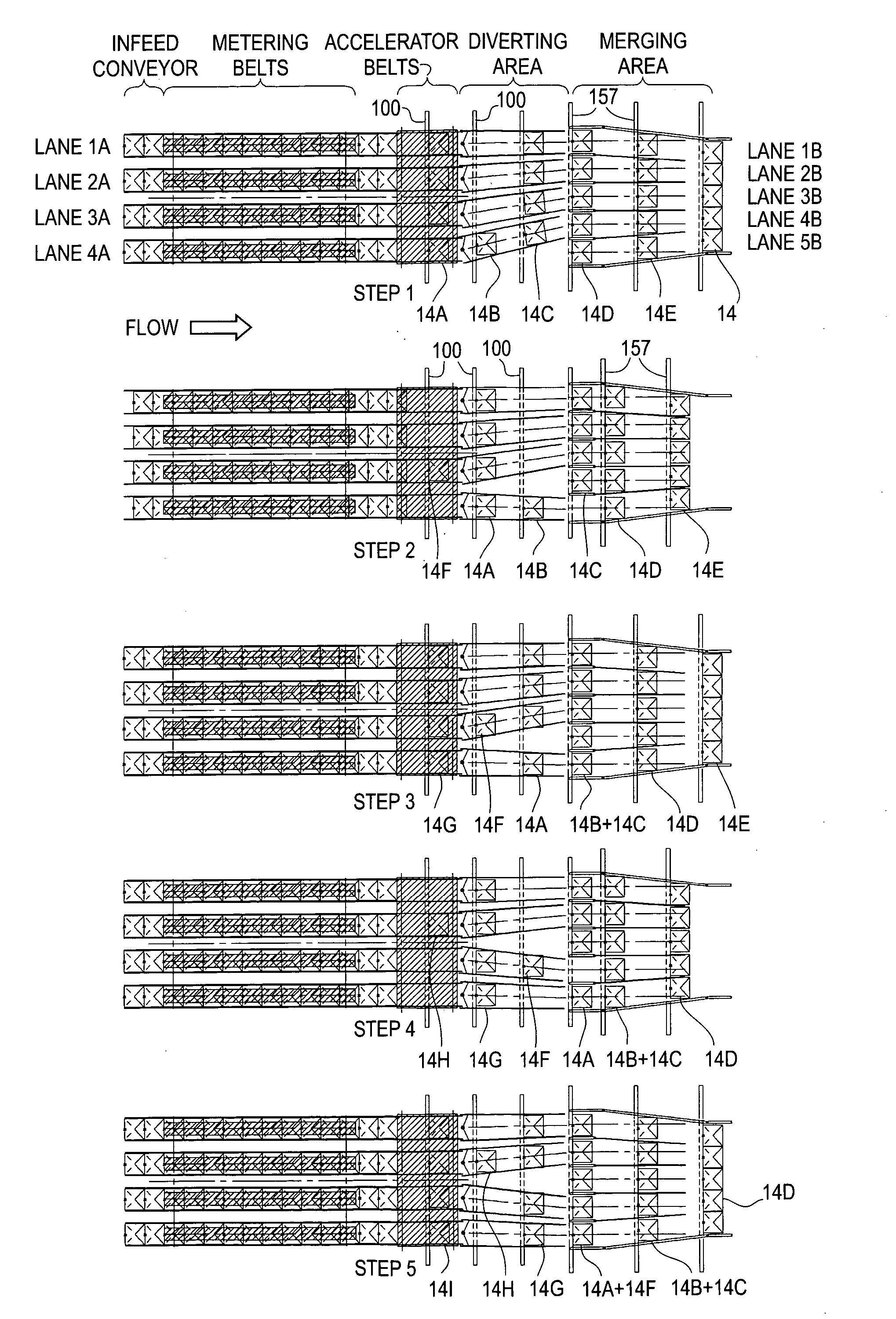

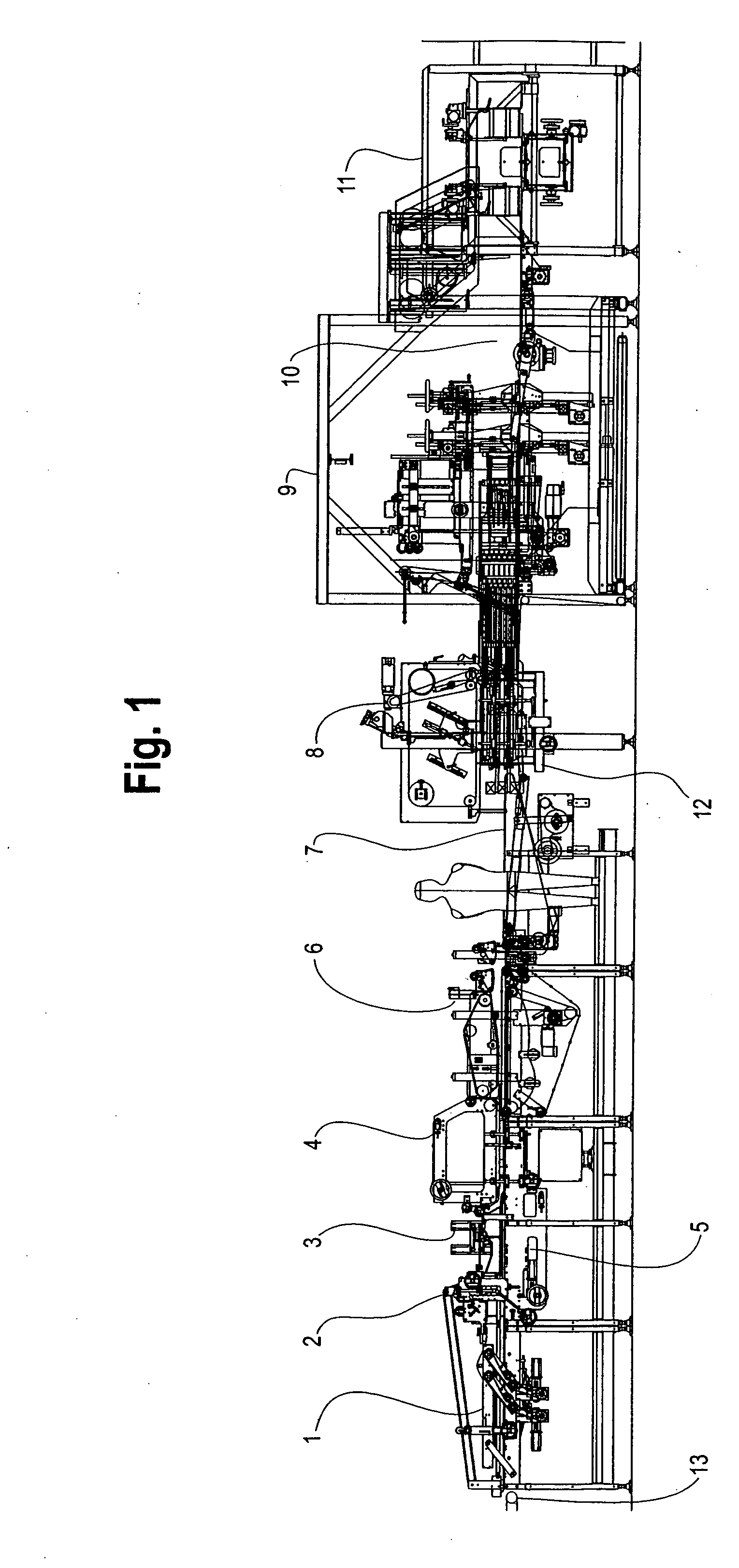

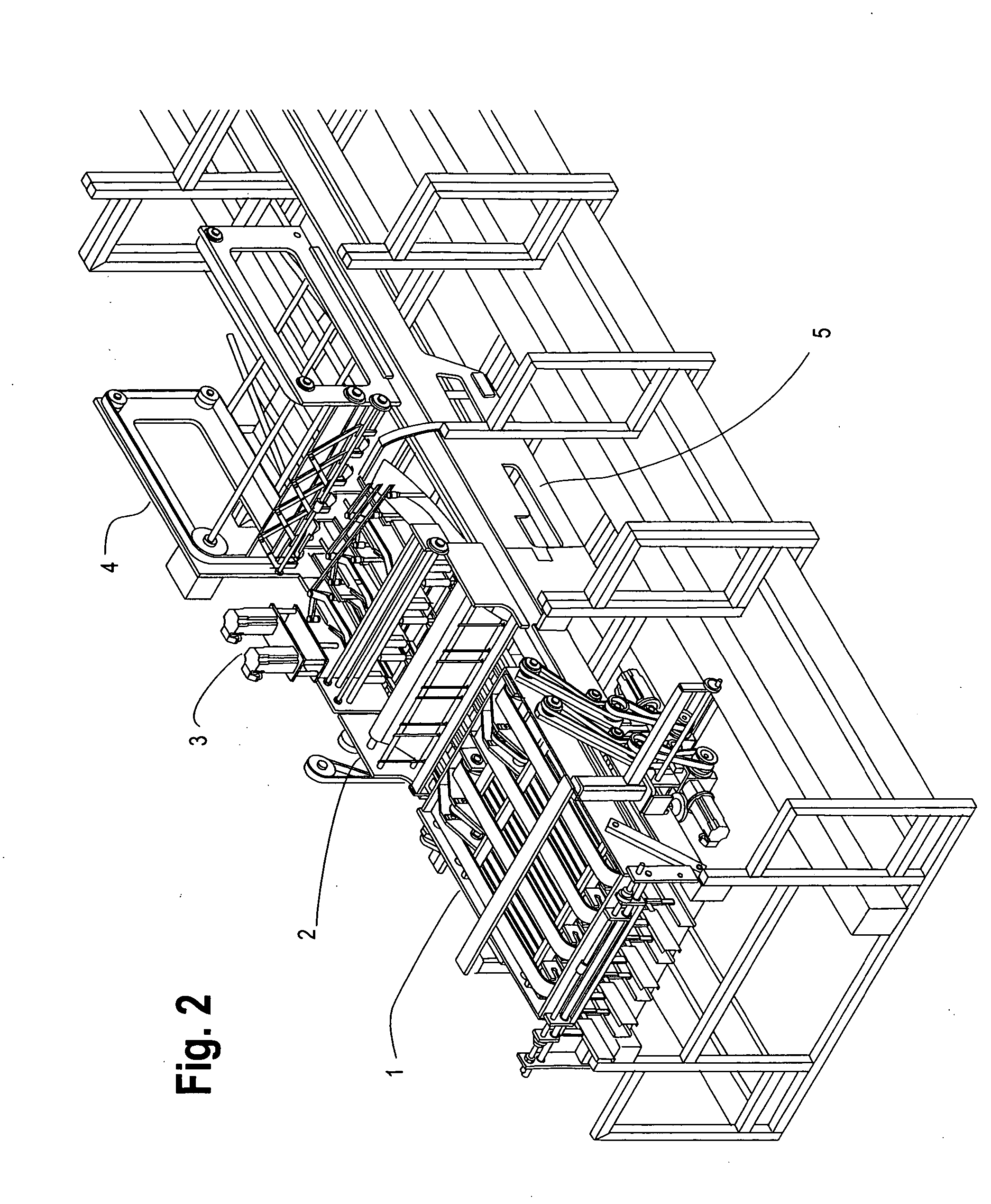

[0039]FIGS. 1-3 illustrate an inventive diverting station integrated in a conventional flow type wrapper, commonly known in the industry and described in U.S. Pat. No. 4,430,844. Product, such as rolled tissue or toweling, is randomly delivered to the wrapper in parallel lanes and presented to the wrapper in a side-by-side relationship by the infeed conveyor 13 at some average rate, where it enters a set of metering belts 1.

[0040] The metering belts are used for feeding items, or groups of items, one after the other to the accelerator belts 2. The metering belts are independently driven and capable of cycling continuously or intermittently to feed one or more items to the accelerator belts. The accelerator belts typically run at a surface speed that is slightly faster than the surface speed of metering belts, providing a gap between successive products to allow a lower, driven flighted conveyor 5 to actuate between successive products, to transport the product through diverting gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com