Faucet assembly with integral water supply shut-off valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

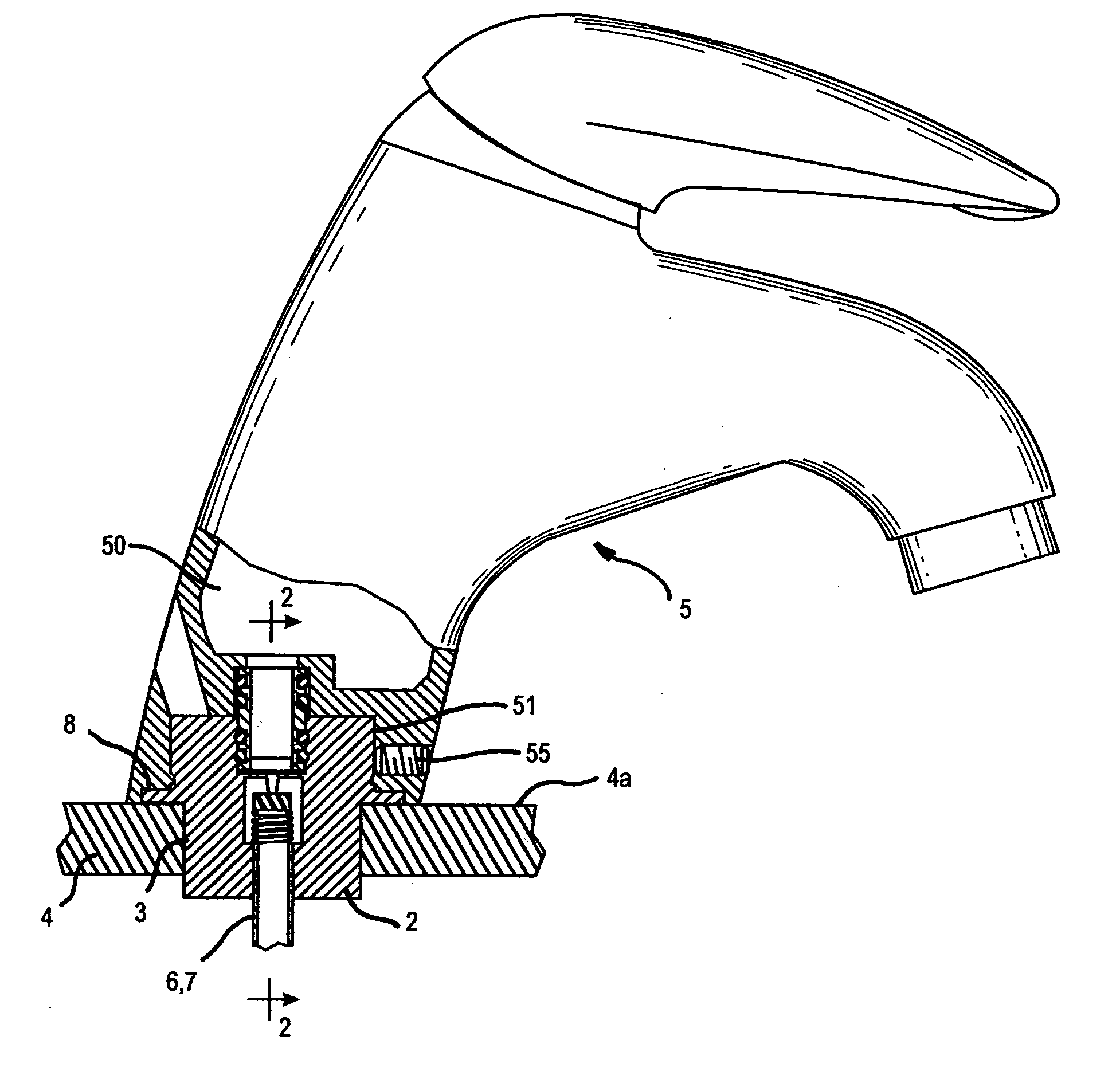

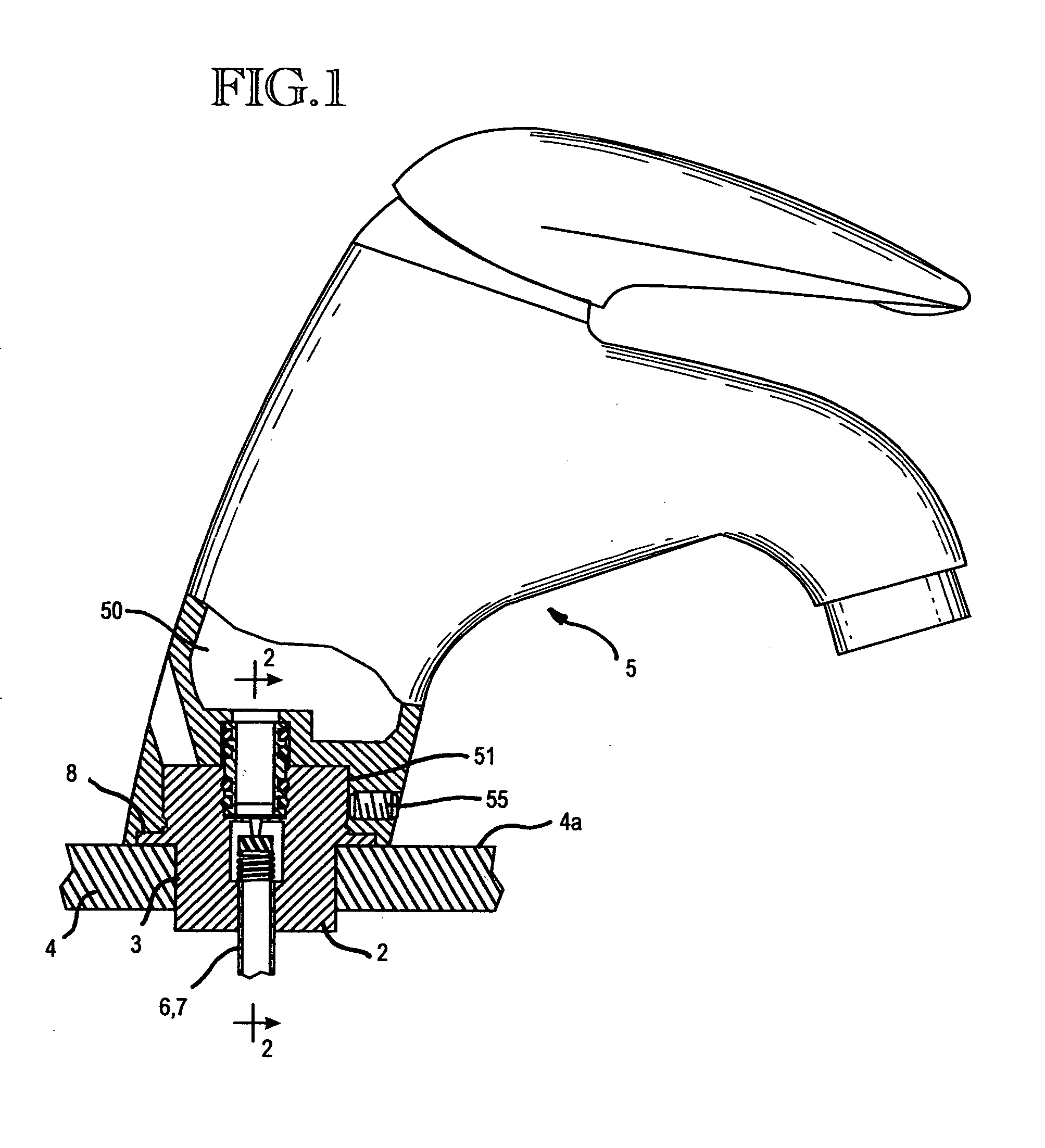

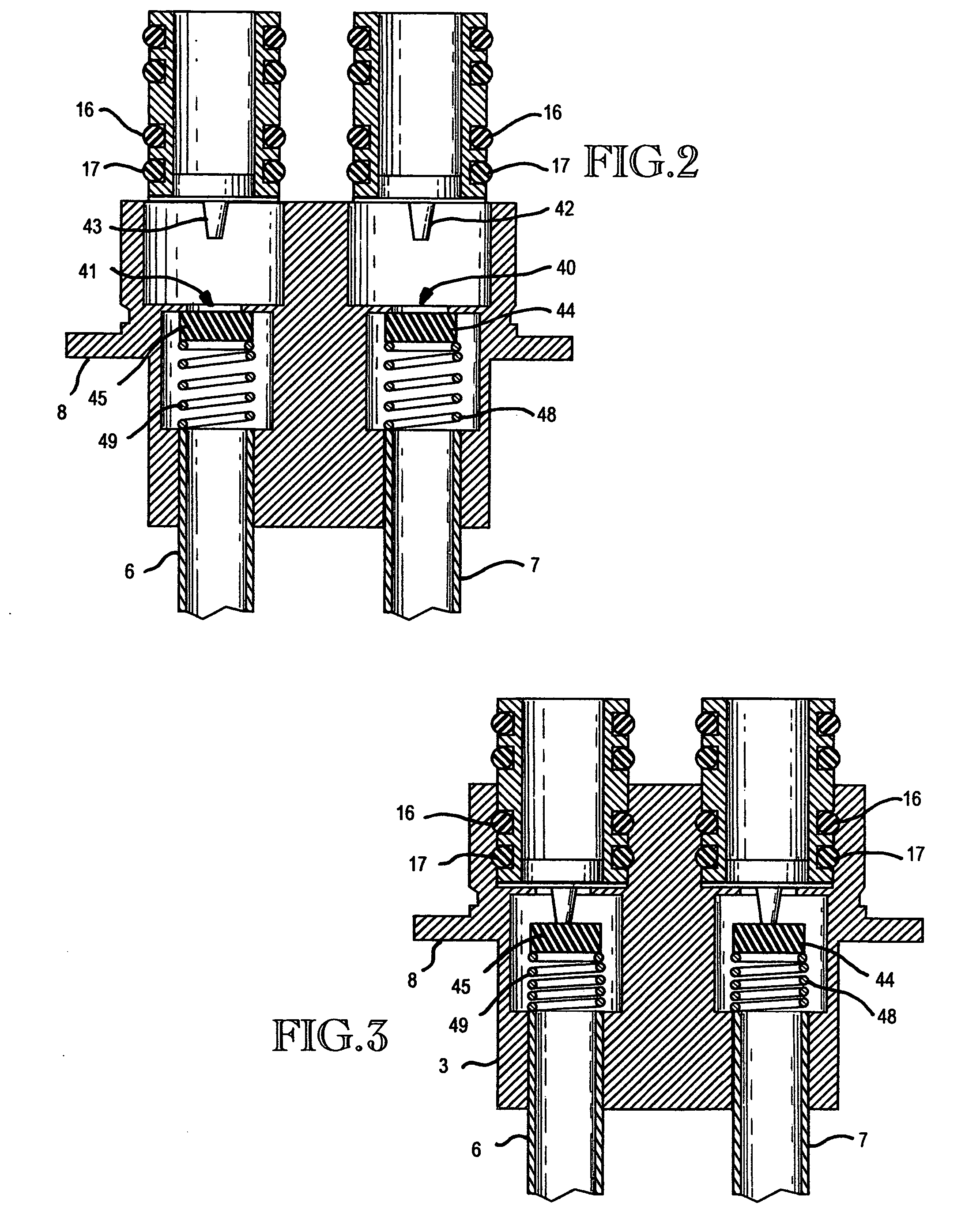

[0021] For a complete understanding of the features and operation of the present invention, reference is now made to the drawings of the invention along with the accompanying figures in which corresponding numerals in the different figures refer to corresponding parts of the invention.

[0022] With reference to the above mentioned FIGS. 1-7, the apparatus comprises a base portion 2, which mounts within a through hole 3 defined in a sanitary fixture 4. Preferably, the sanitary fixture 4 is a sink, washbasin, bidet or the like. An upper portion of the base portion 2 protrudes above the sanitary fixture 4 and can be housed within a lower cavity 51 of the faucet apparatus 5, and is removably fixed thereto.

[0023] The base portion 2, preferably of a substantially cylindrical shape, is coupled coaxially in the through hole 3 so as to be aligned with a vertical axis and in a perpendicular attitude to a upper face 4a of the sanitary fixture 4.

[0024] A relatively narrow portion of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com