Particulate trap regeneration control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

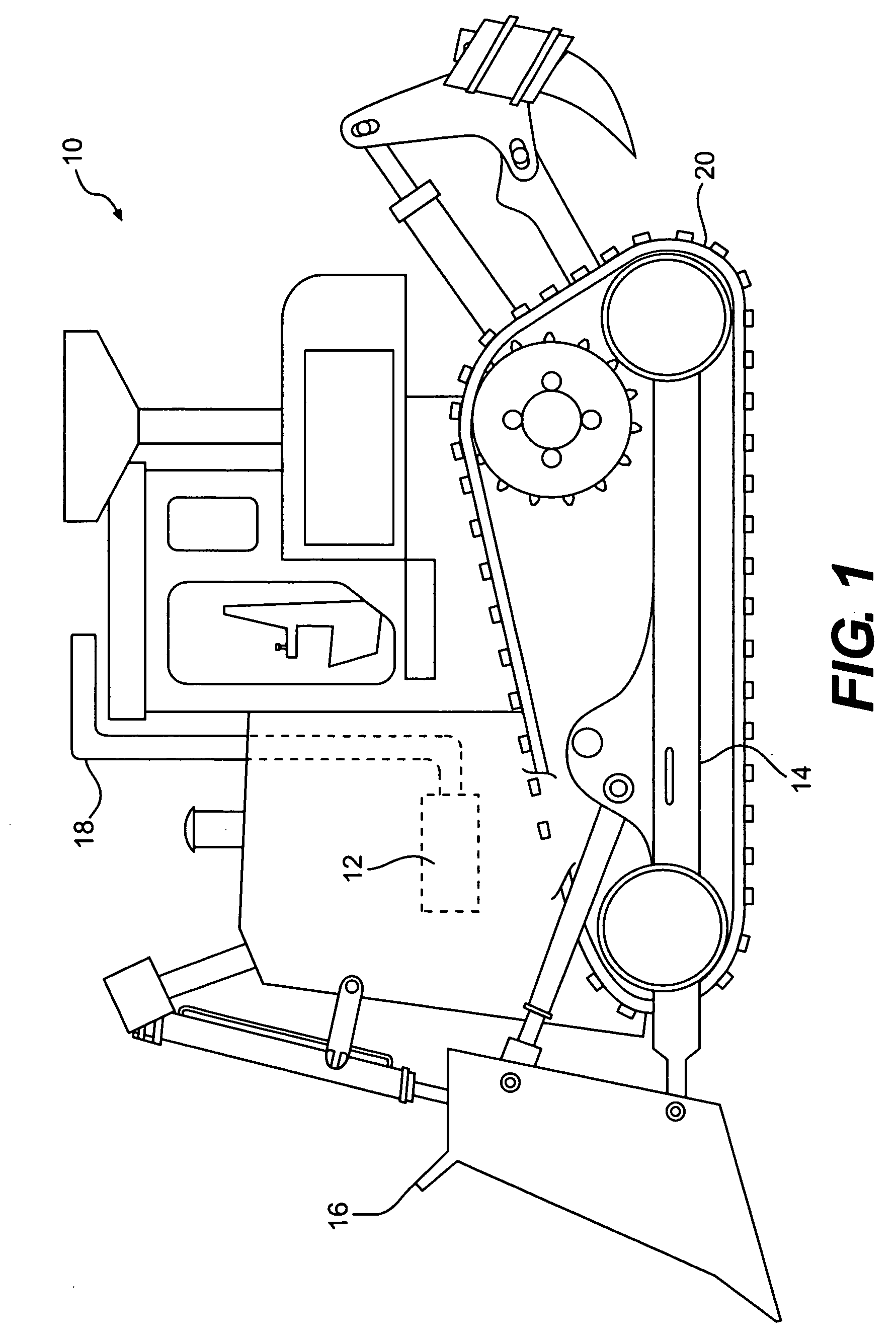

[0014]FIG. 1 provides a pictorial illustration of a work machine 10. Work machine 10 may include engine 12. Work machine 10 may also include a frame 14 and a work implement 16. Engine 12 may be operably connected to an exhaust system 18. Engine 12 may include a diesel engine, a gasoline engine, or any other power-producing device. Work machine 10 may also include a traction device 20.

[0015] While work machine 10 is shown as a track type tractor, work machine 10 may include various types of machines. For example, work machine 10 may be a truck, wheeled tractor, dump truck, automobile, on-highway vehicle, off-highway vehicle, skid-steer, stationary generator, or any other device that includes an engine that generates an exhaust stream.

[0016] Exhaust system 18 may include components used to transfer exhaust produced by engine 12 or other exhaust producing devices to the atmosphere. For example, exhaust system 18 may include an exhaust manifold (not shown), a particulate filter or any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com