Stair tread structure

a technology for stair treads and structures, applied in the direction of treads, flooring, construction, etc., can solve the problems of inconvenient use, dislocation and disassembly of the tread body, and inconvenient use so as to achieve convenient and fast assembly, convenient and fast manufacturing of the tread body, and economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

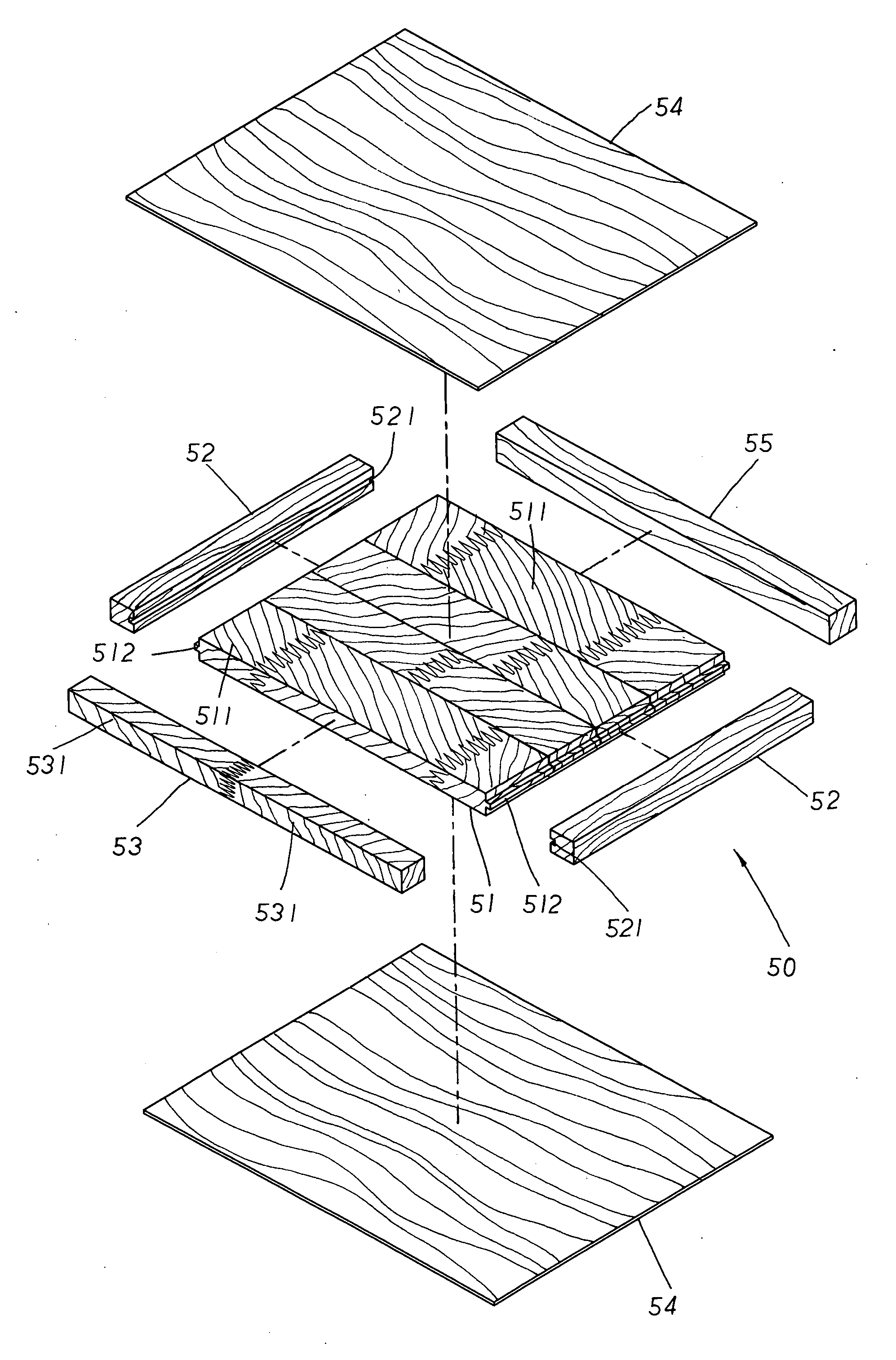

[0021] Please refer to FIG. 4. The present invention is related to a stair tread structure, including a tread body 50 made up of a core layer 51, a plurality of lateral connecting members 52, a tread end member 53, a plurality of external connecting sheets 54, and an elongate nose member 55. The core layer 51 and the tread end member 53 are respectively made up of one or more than one board bodies 511, 531 that, integrally processed and firmly bonded into one piece, can be made of recycled wooden material, plywood, sawdust, and other lower quality materials. Besides, the core layer 51 is provided with a pair of lateral coupling portions 512 symmetrically protruding at both end surfaces thereon, and each lateral connecting member 52 is equipped with a lateral coupling groove 521 disposed at one end surface therein correspondingly matching to the lateral coupling portion 512 of the core layer 51 for mutual engagement therewith.

[0022] Please refer to FIGS. 5 through 11 inclusive. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com