Skipping frequencies for variable speed controls

a variable speed control and frequency control technology, applied in the direction of positive displacement liquid engine, pump parameter, piston pump, etc., can solve the problem that the control does not necessarily determine the required operating frequency of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

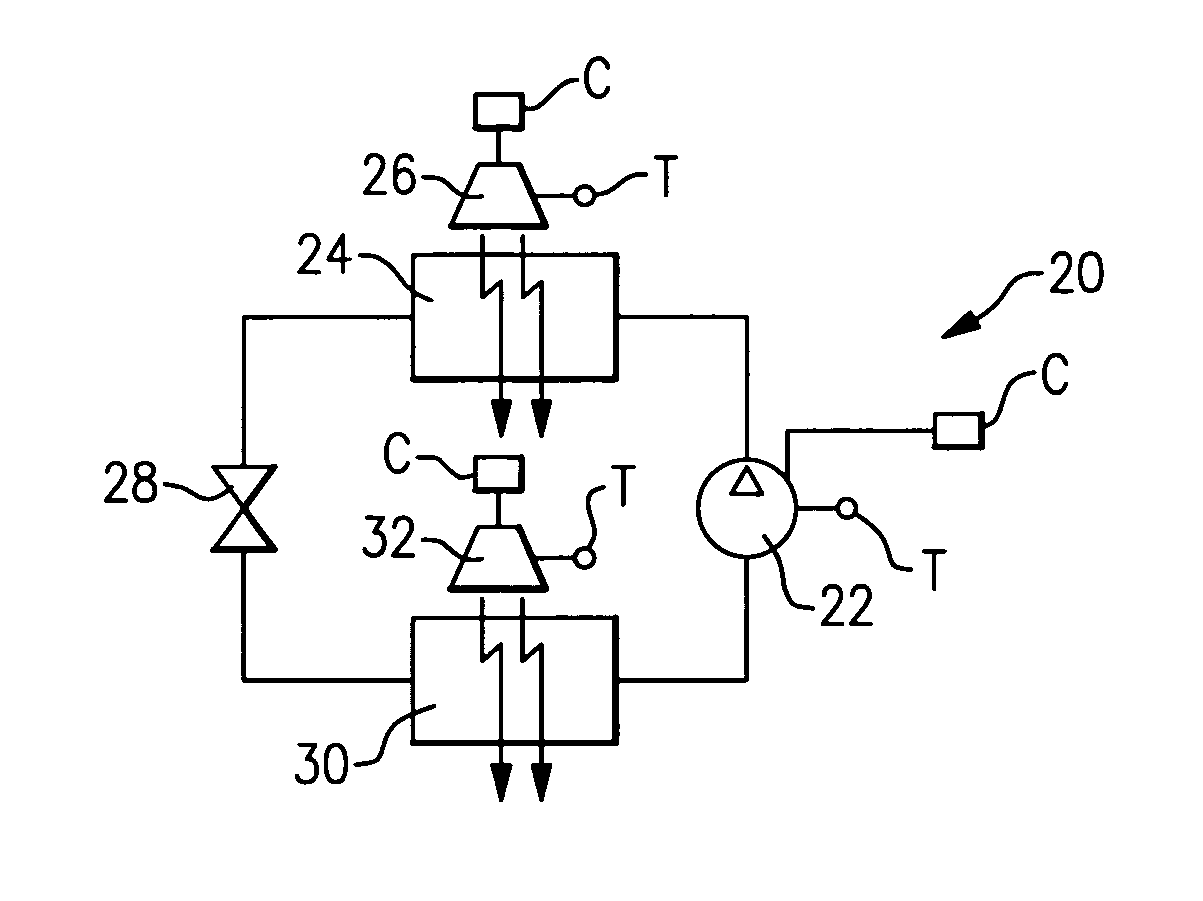

[0016]FIG. 1 shows a refrigerant system 20 incorporating compressor 22 delivering a compressed refrigerant to a heat exchanger 24. The heat exchanger 24 is associated with a fan 26 for driving air over the heat exchanger 24. The fan 26 is associated with a motor, as known. A variable speed control C and a transducer T are associated with the fan 26. The variable speed control C drives the motor for the fan 26, and the transducer T may identify one of the parameters associated with vibration level at the fan.

[0017] Refrigerant passes from the heat exchanger 24 downstream to an expansion device 28, and then to another heat exchanger 30. The heat exchanger 30 is associated with its own fan 32. A variable speed motor control C and transducer T are also associated with the fan 32.

[0018] The refrigerant passes from the heat exchanger 30 back to the compressor 22. As is known, a motor drives a compressor unit 22, and a variable speed control C and a transducer T are associated with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com