Overhead baggage rack unit of railway car

a baggage rack and railway car technology, applied in the direction of axle-box lubrication, railway bodies, packaging, etc., can solve the problems of neither cost-effective nor light weight, and achieve the effect of cost-effectiveness and light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

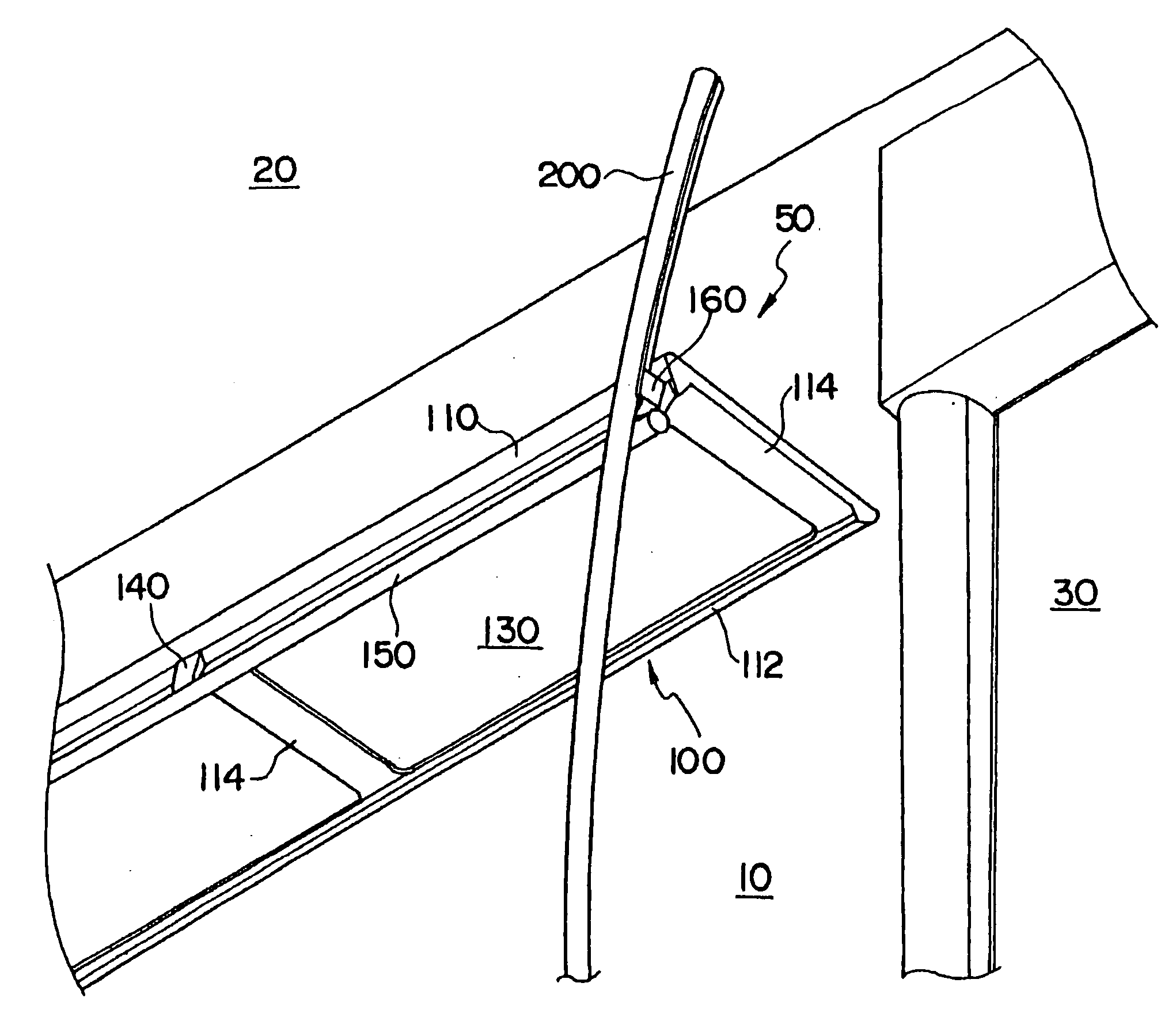

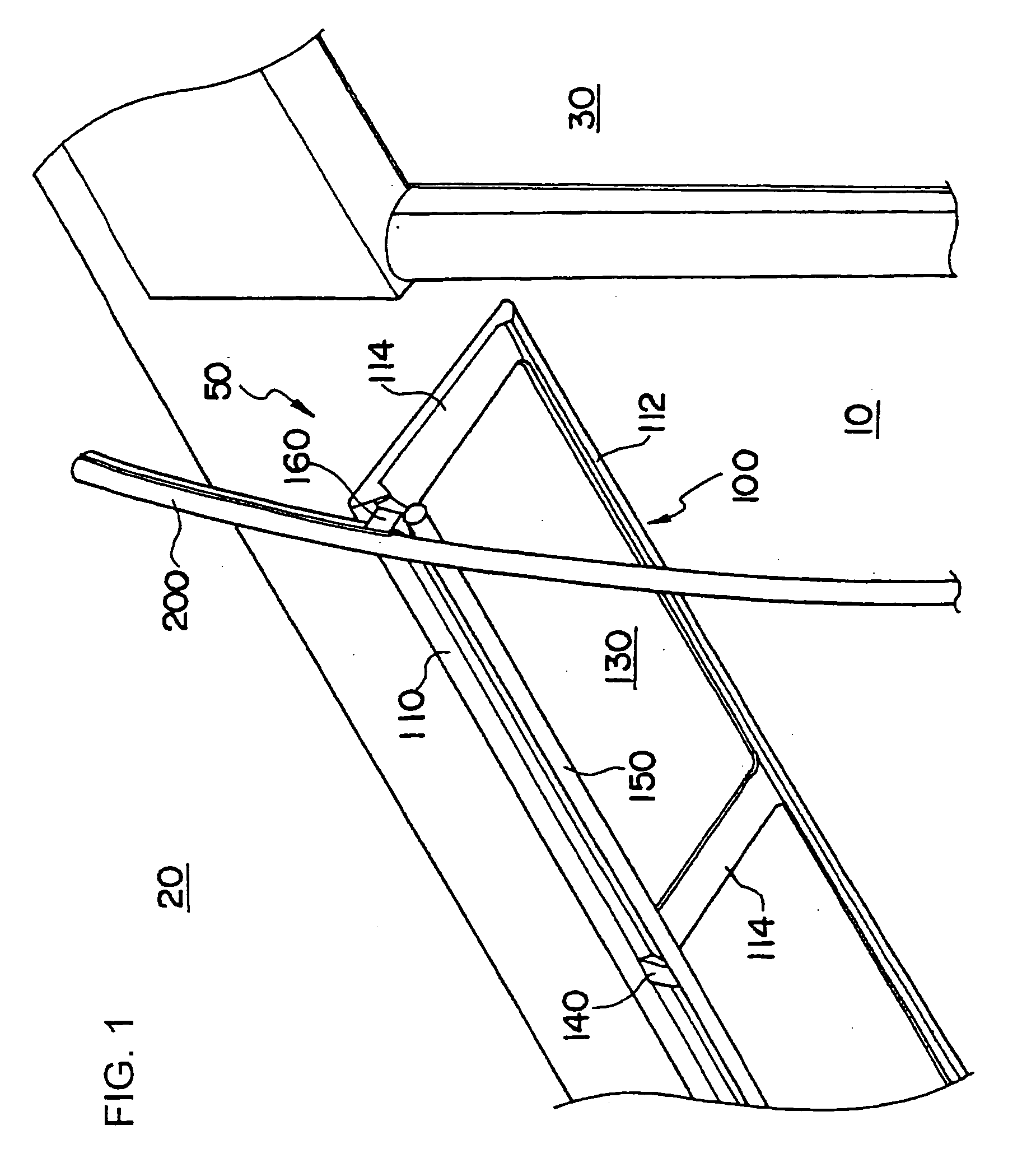

[0022]FIG. 1 is a perspective view showing the general structure of an overhead baggage rack unit according to the present invention.

[0023] A railway car is composed of an underframe not shown for supporting a floor of the car, side frames 10, a roof frame 20 and so on. Interior panels are mounted on the inner sides of the side frames 10 and the roof frame. Doors 30 for entering and exiting the car and windows are disposed on the side frame 10.

[0024] The overhead baggage rack unit denoted as a whole by reference number 50 includes an overhead baggage rack body 100 and a pole 200 for supporting the overhead baggage rack body 100. The overhead baggage rack body 100 is connected to the pole 200 via a bracket portion 160 described in detail later.

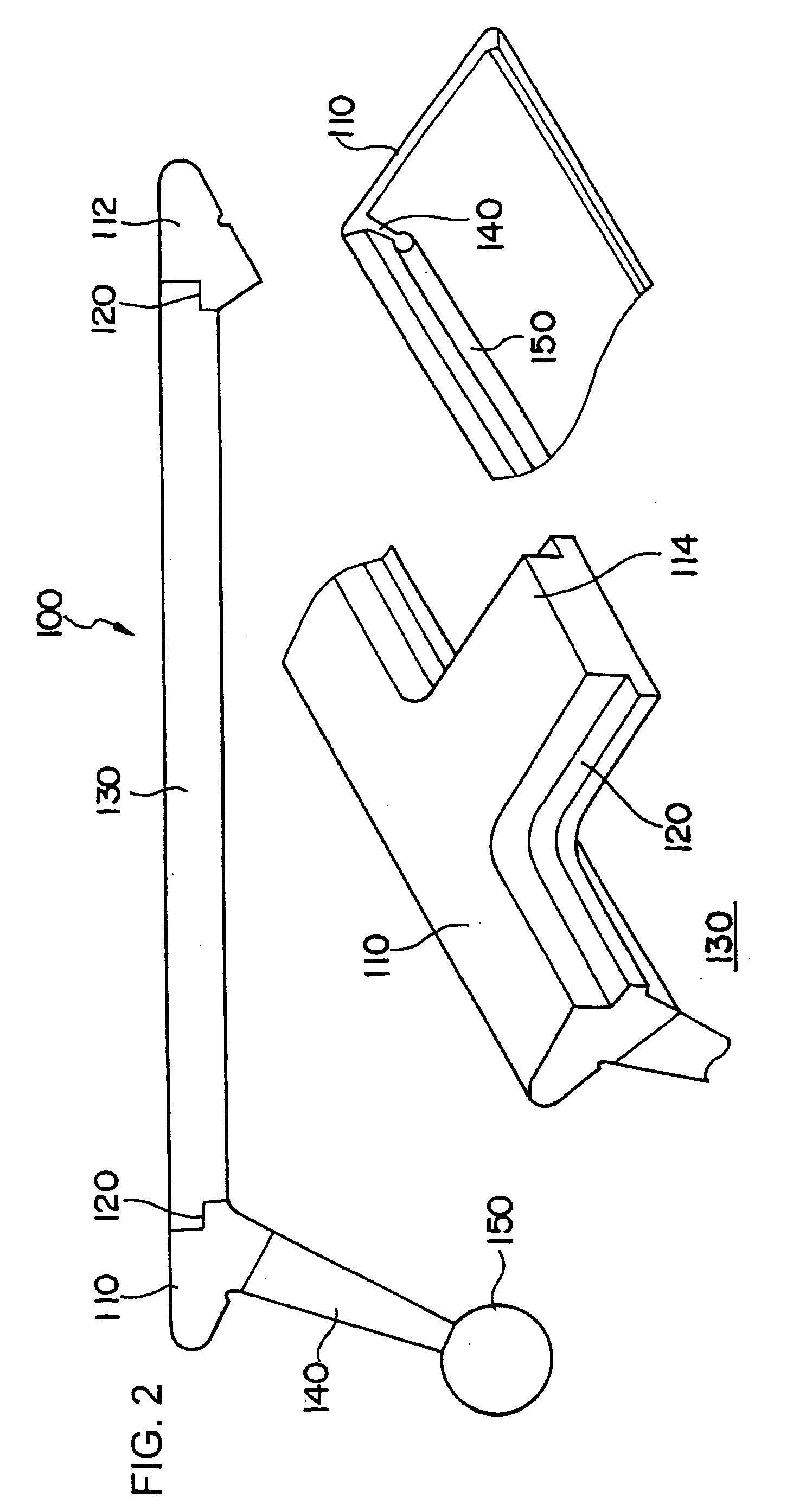

[0025]FIG. 2 illustrates the details of the overhead baggage rack body 100.

[0026] The overhead baggage rack body 100 has an integrated structure formed by extruding aluminum alloy, in which the finished product is formed by cutting unnecess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com