Method for manufacturing tool handle

a manufacturing tool and handle technology, applied in the direction of manufacturing tools, identification means, instruments, etc., can solve the problems of fading of printed the chance of being disengaged from the handle, and the inability to print or form raised indicia with delicacy or beautiful patterns or marks or words, etc., to achieve the effect of retaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

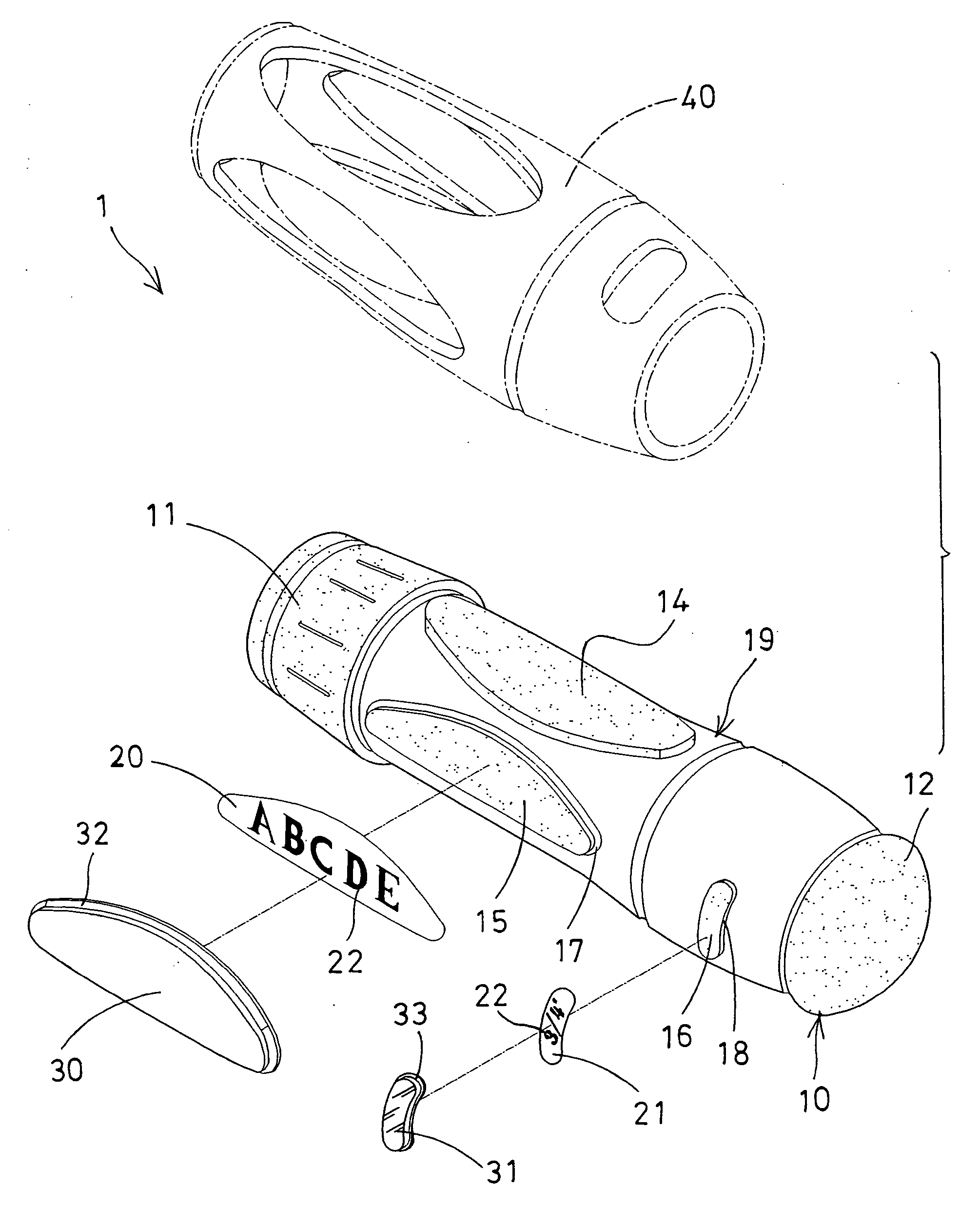

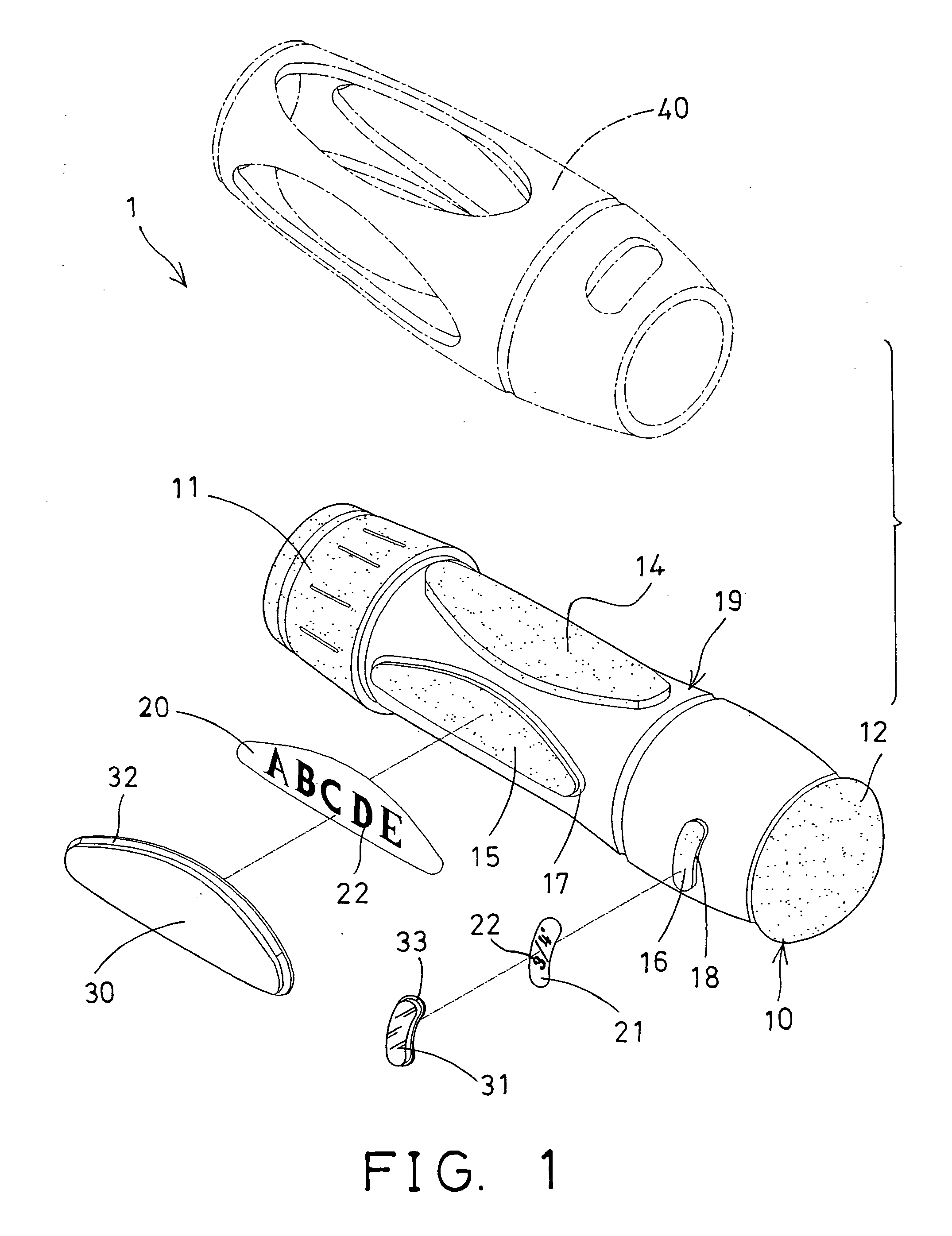

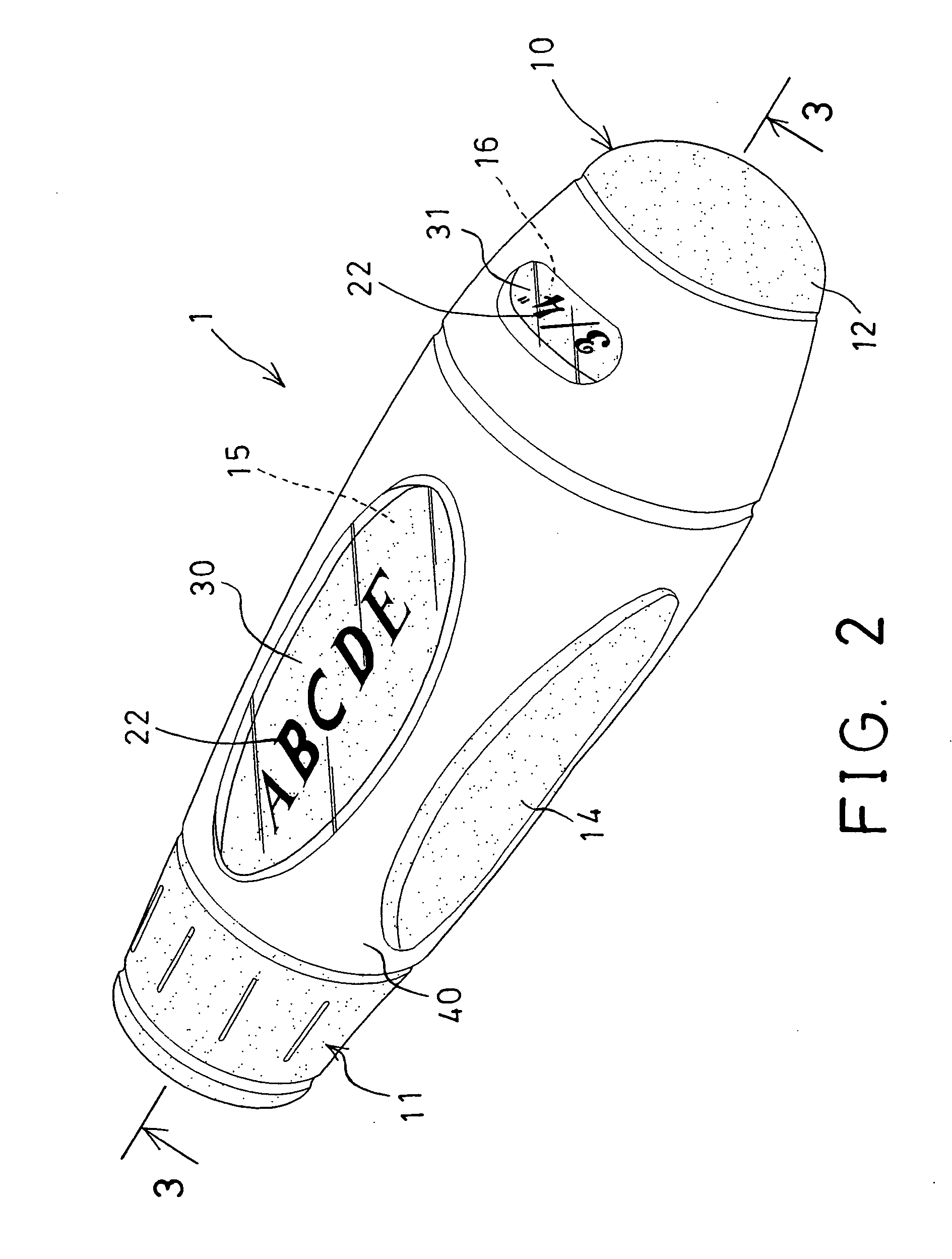

[0026] Referring to the drawings, and initially to FIGS. 1-3, a method in accordance with the present invention is provided for manufacturing a tool handle 1 which comprises a handle body 10 including a front peripheral protrusion 11 and a rear peripheral protrusion 12 formed thereon or extended therefrom two end portions, to form or define a peripheral recess 13 between the peripheral protrusions 11, 12 or in a middle portion 19 thereof, best shown in FIGS. 3, 7.

[0027] The tool handle 1 includes one or more projections 14, 15, 16 extended from the middle portion 19 of the handle body 10, and extended into the peripheral recess 13, and preferably includes one or more peripheral grooves 17, 18 formed around some of the projections 15, 16 respectively, to form a prototype as shown in FIG. 4. One or more decorative or identifying plates or panels 20, 21 may further be provided and attached onto the projections 15, 16 respectively (FIG. 5) and may be printed or formed or applied with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| semi-transparent | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com