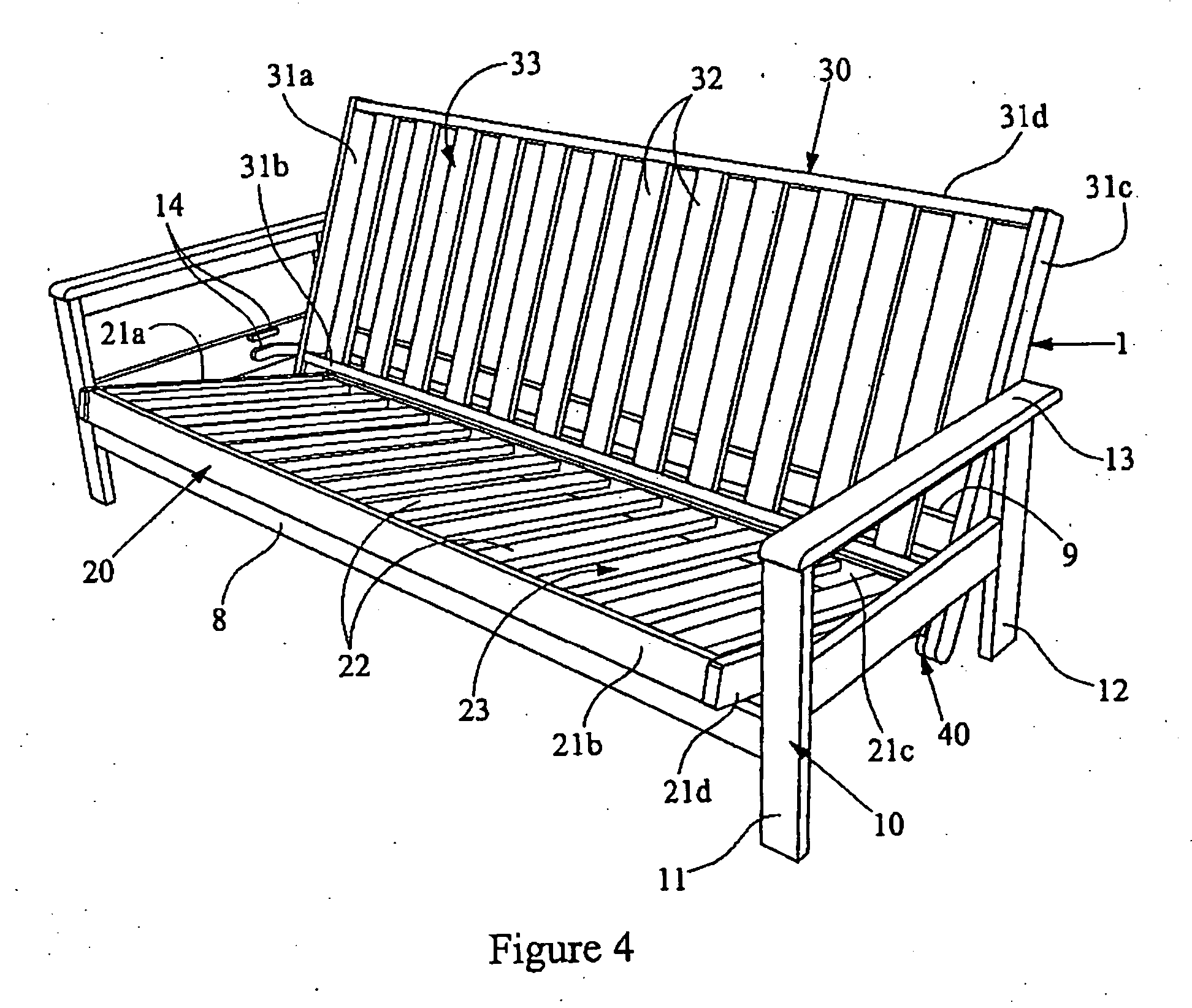

Futon sofa bed

a futon and sofa bed technology, applied in the field of futon sofa beds, can solve the problems of not always making the futon sofa bed easy to use, awkward user experience, and high cost, and achieve the effect of low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

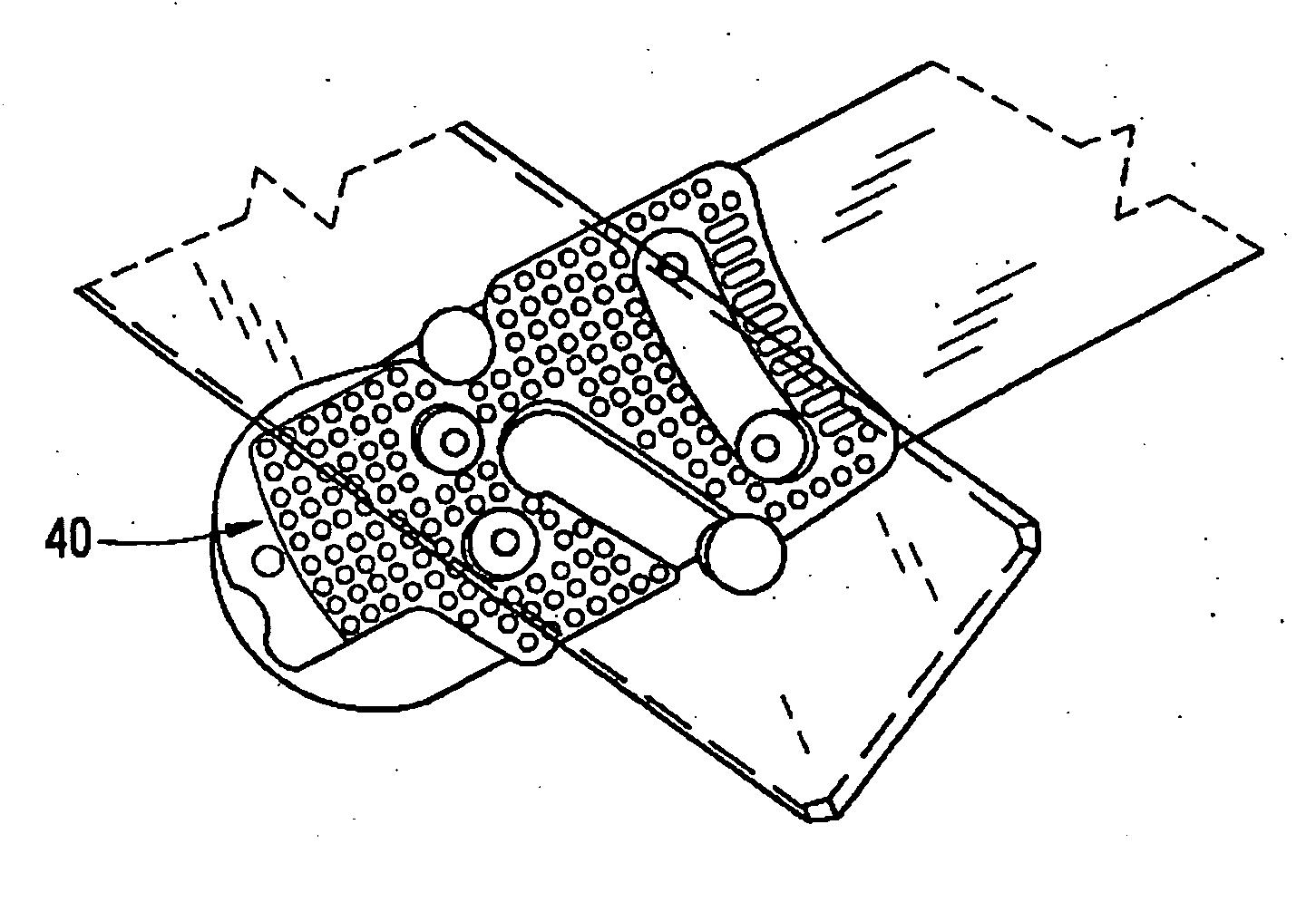

Image

Examples

Embodiment Construction

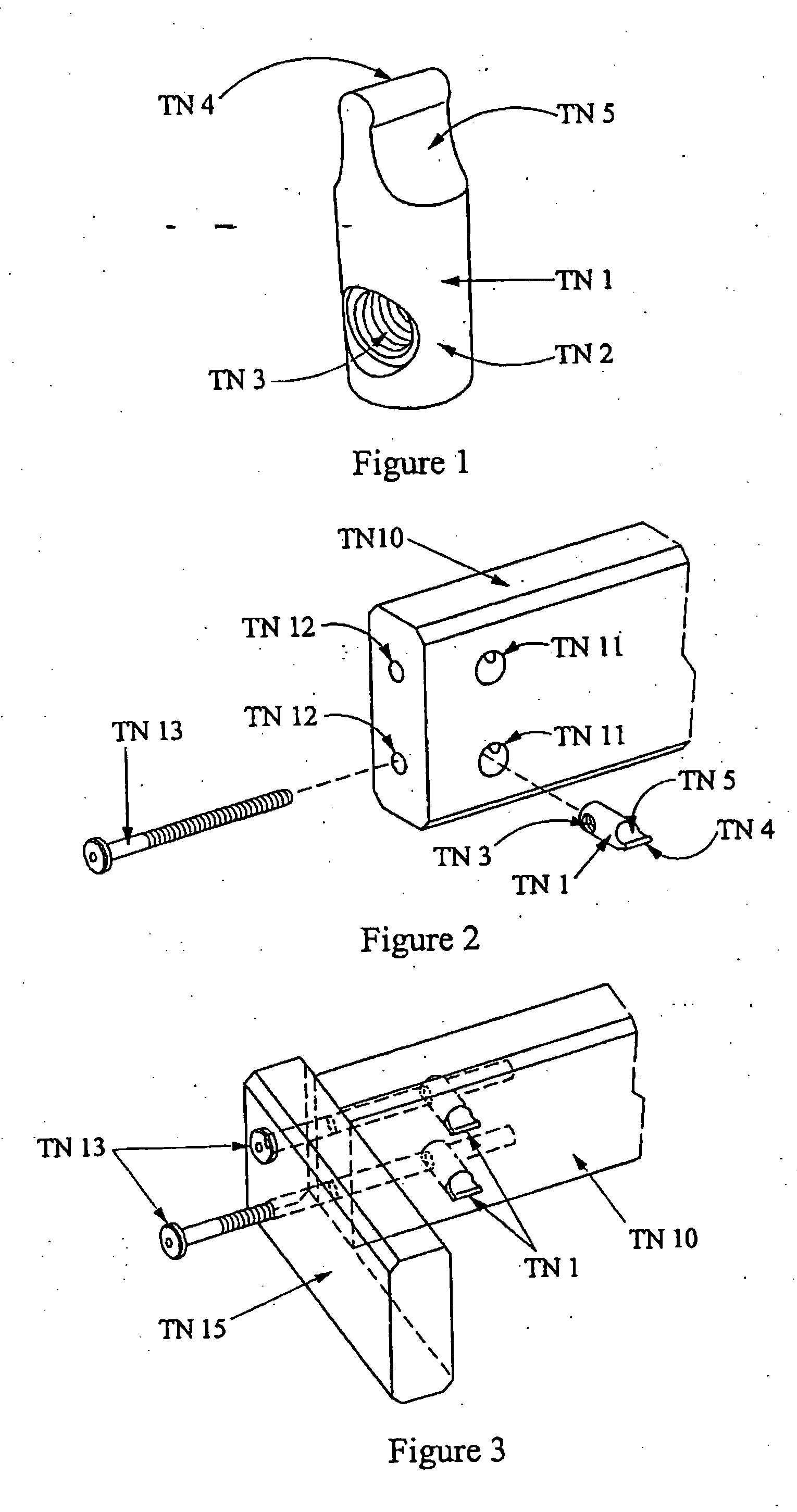

[0084] 1. Finger Held Barrel Nut

[0085] Below is described a threaded barrel nut TN 1 which, when used with a threaded bolt TN 13 in the described manner, allows easy insertion, manipulation and alignment as compared to conventional barrel nuts commonly available.

[0086] Referring to FIGS. 1-3 a threaded barrel nut TN 1, with a generally cylindrical shape, is formed with a thumb and finger grip TN 4 and TN 5 at one end, with said finger grip designed to extend outside of hole TN 11 (when the barrel nut TN 1 is seated in hole TN 11) and extend beyond the surface of member TN 10. Additionally a threaded hole TN 3 is bored perpendicularly (at a substantially 90.degree. angle) to the length of the cylindrical shank TN 2, and forming a through-hole, preferably open at both ends.

[0087] The general purpose of the barrel nut being to fixedly attach any member TN 15 (also being made of a variety of materials, in all shapes and sizes) to member TN 10 by passing bolt TN 13 through both member...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| leveraging distance | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com