Surface light source device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

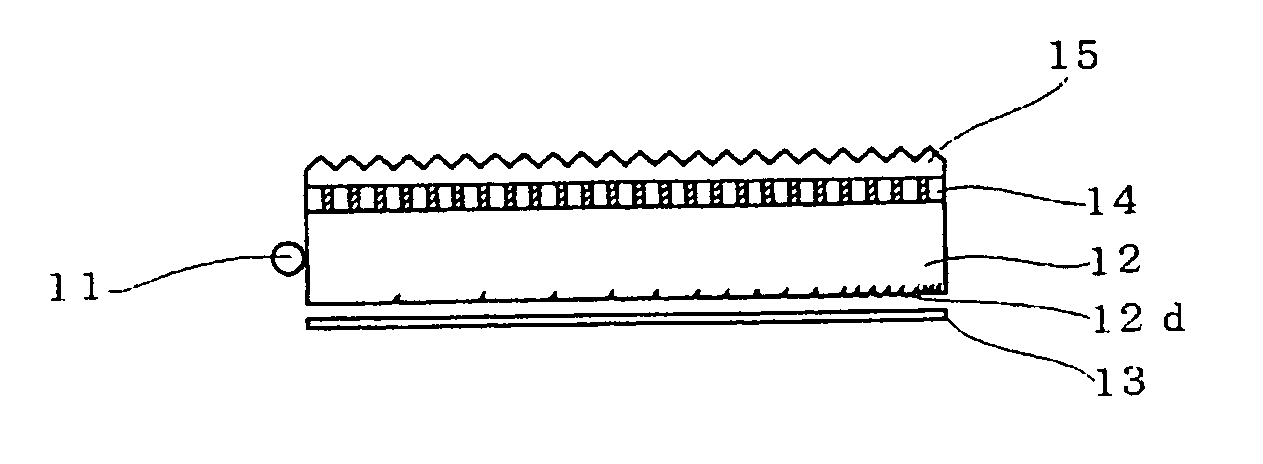

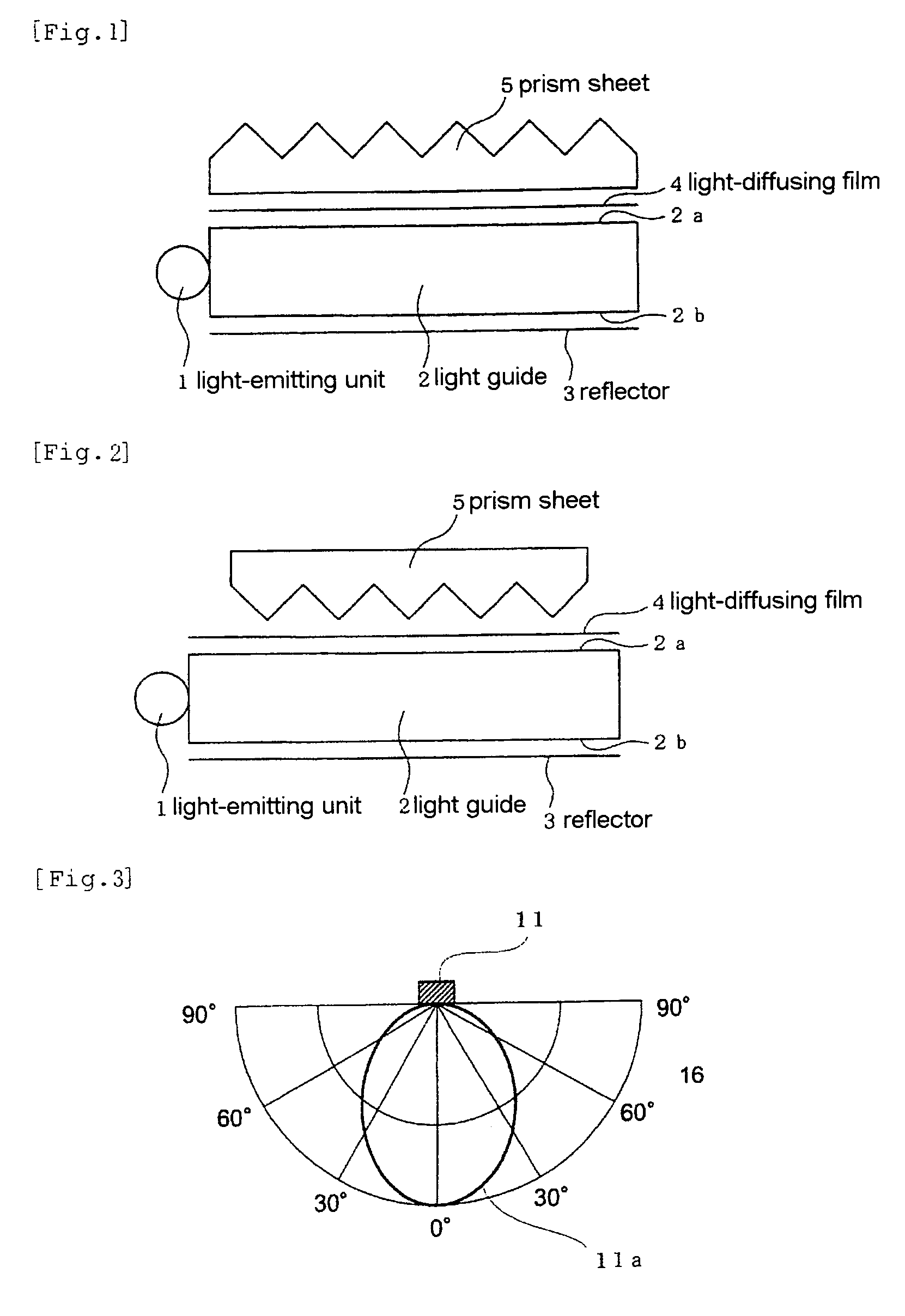

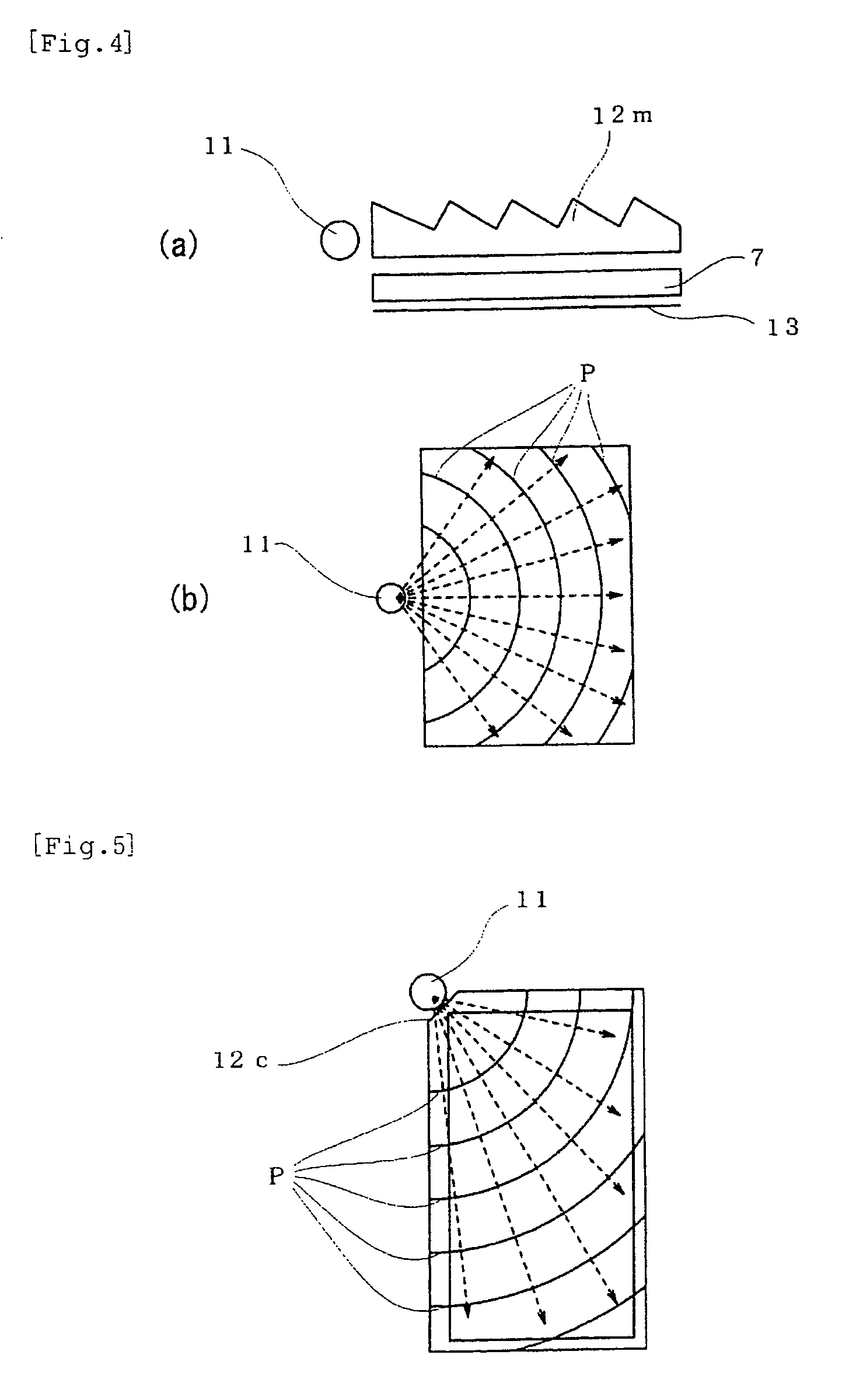

[0057] The surface light source device of the first embodiment of the invention will now be described with reference to FIG. 4(b) and FIG. 6. The surface light source device of the first embodiment, as shown in FIG. 6, comprises point light source 11, light guide 12, reflector 13, directional light-diffusing film 14, and prism sheet 15. Point light source 11 comprises a single chip-type LED, and this chip-type LED was positioned facing the central part of the end surface (end surface to which light is incident) of light guide 12, as shown in FIG. 4(b). Light guide 12 was formed of polycarbonate resin, and a plurality of concentric circular diffusion patterns centered on the light-emitting unit were formed on the lower surface of the light guide. The diffusion patterns were formed as depression 12d with a cross-section that was triangular or roughly semi-circular (half-oval) in shape, each diffusion pattern extending in a direction which intersected the direction connecting the light...

embodiment 2

[0060] A second embodiment of the invention will now be described. In the surface light device of the first embodiment, the reflector was provided separately to the light guide, but apart from the fact that an aluminum film was formed by vacuum deposition on the surface formed on the diffusion pattern of the lower surface of the light guide, the remainder of the structure was identical to that of Embodiment 1. By forming a thin metal film directly on the lower surface of the light guide, the light incident on the optical sheet can be reflected at the light-reflecting surface comprising the thin metal film and returned to the light guide, making it possible to ensure reflection of the light more reliably than the device of Embodiment 1 which reflects light using total reflection, and it is thus possible to improve the efficiency of light use.

embodiment 3

[0061] With the surface light source device of Embodiment 3, the device was made with an identical structure to that of Embodiment 1 apart from the fact that directional light-diffusing film 14 of FIG. 6 was positioned on prism sheet 15. When this surface light source device was used to illuminate a liquid crystal panel, a bright image display device with no unevenness in brightness was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com