Drink cartridge and method of manufacturing the same

a technology of drinking water and cartridges, which is applied in the direction of packaging, packaging foodstuffs, packaged goods, etc., can solve the problems of high manufacturing cost, unacceptable amount of soluble solids remaining in the pouch or sachet after brewing, and waste of soluble solids, so as to prevent clogging of the bottom filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

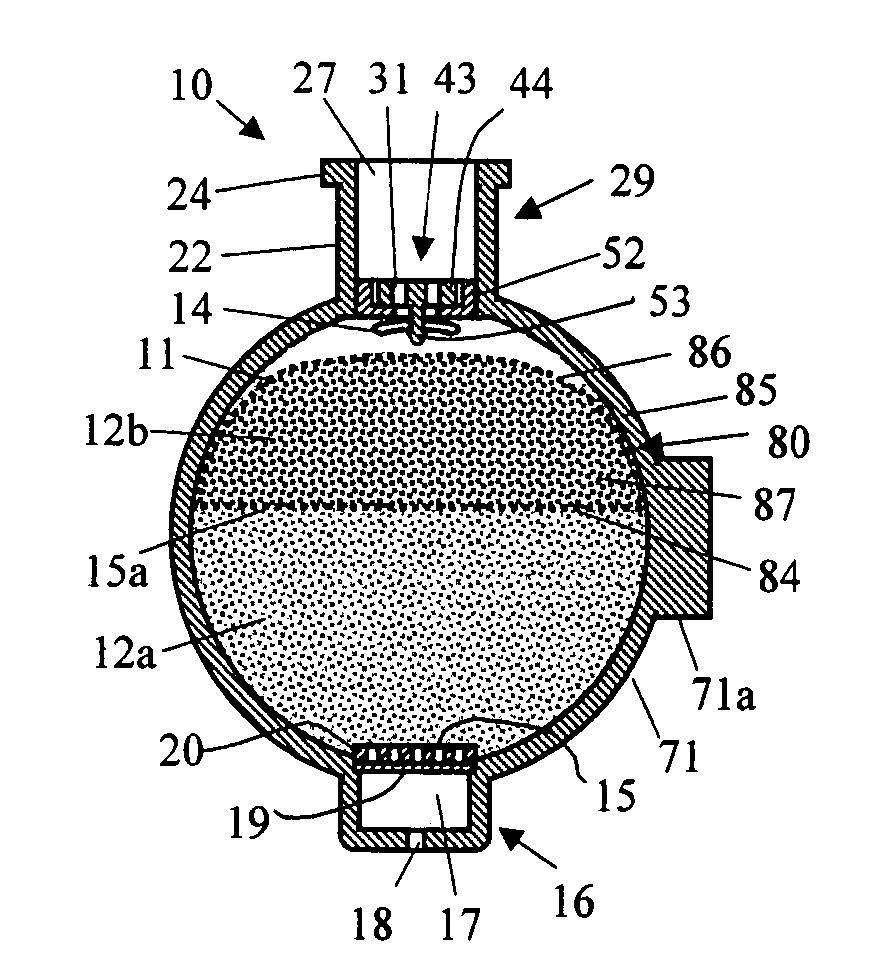

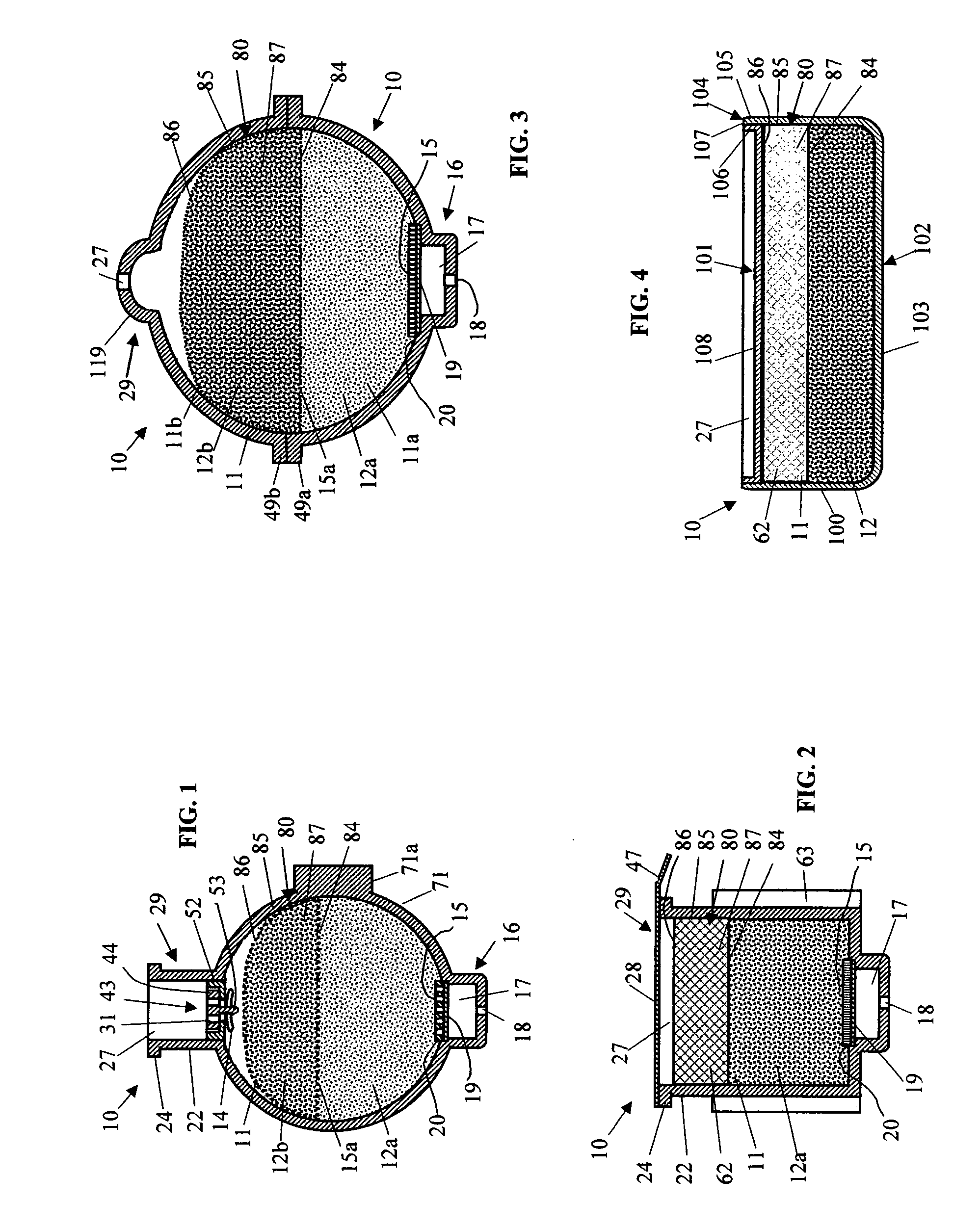

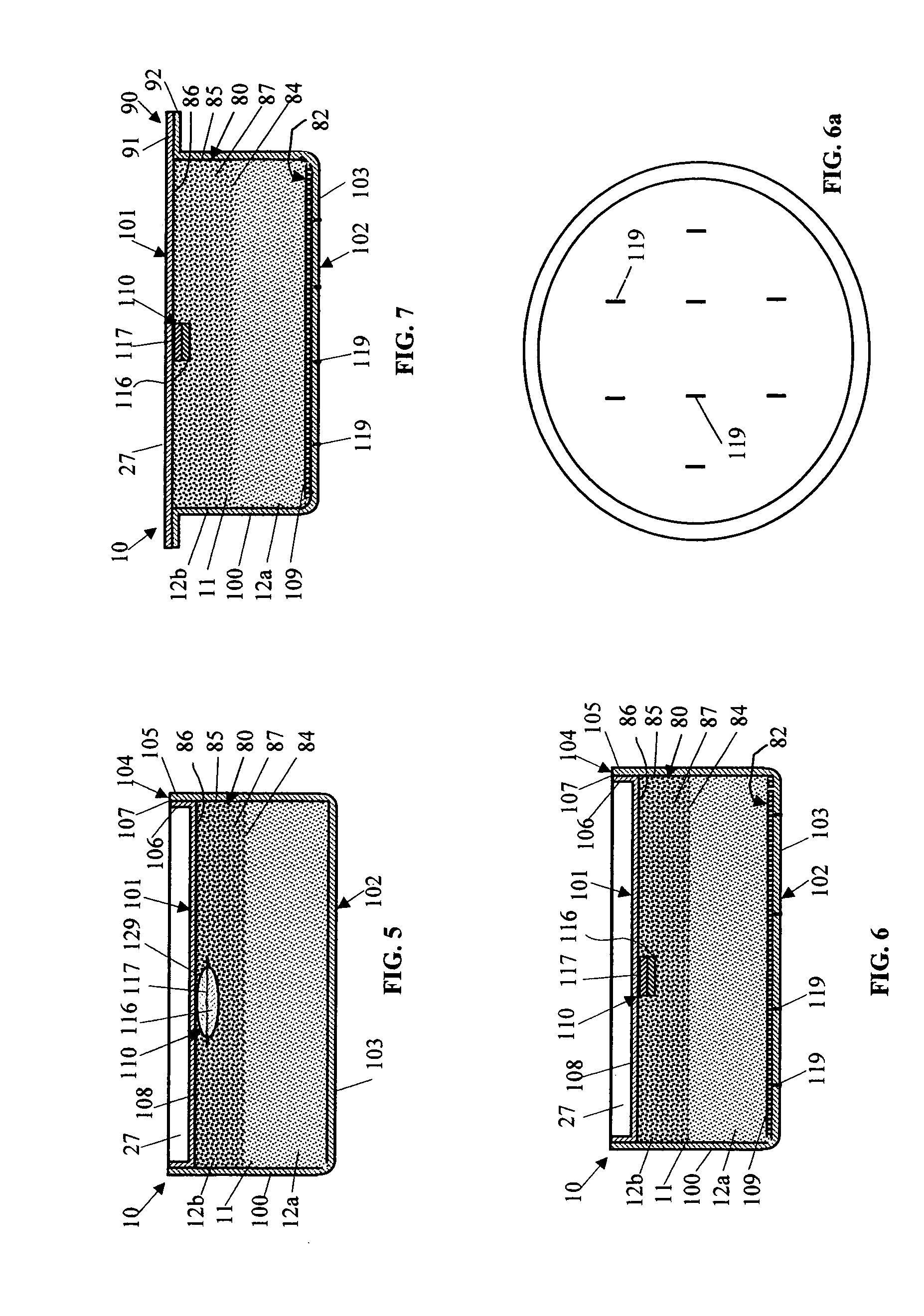

[0029]FIG. 1 shows a drink cartridge 10 that is identical to that in the FIG. 3 of the parent application Ser. No. 09 / 748,495. The cartridge 10 comprises a cartridge inlet 29, a spherical chamber 11, a cartridge outlet 16, and a filter 15 and barrier film 19 attached to the bottom of the chamber 11 to cover the cartridge outlet. The cartridge inlet has a cylindrical body 22, a cylindrical opening 27 and a flange 24 for connection to a drink apparatus. The cartridge outlet has a collection chamber 17 for collecting the drink and an opening 18 for discharging the drink directly into a receptacle such as a carafe or cup. The cartridge inlet 29, chamber 11 and cartridge outlet 16 are made as a single, integral body without any seam to reduce the chance of leakage when the cartridge 10 is exposed to high pressure as well as to lower the cost. The chamber 11 is made rigid to function as a handle to allow the user to hold to mount the cartridge 10 to the drink apparatus. A valve 43 is fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com