Run flat tire insert system

a technology of insert system and tire, which is applied in the field of run flat tire insert system, can solve the problems of tire overheating and falling apart, and achieve the effects of minimizing heat buildup, convenient disassembly and installation, and convenient mounting in the tir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

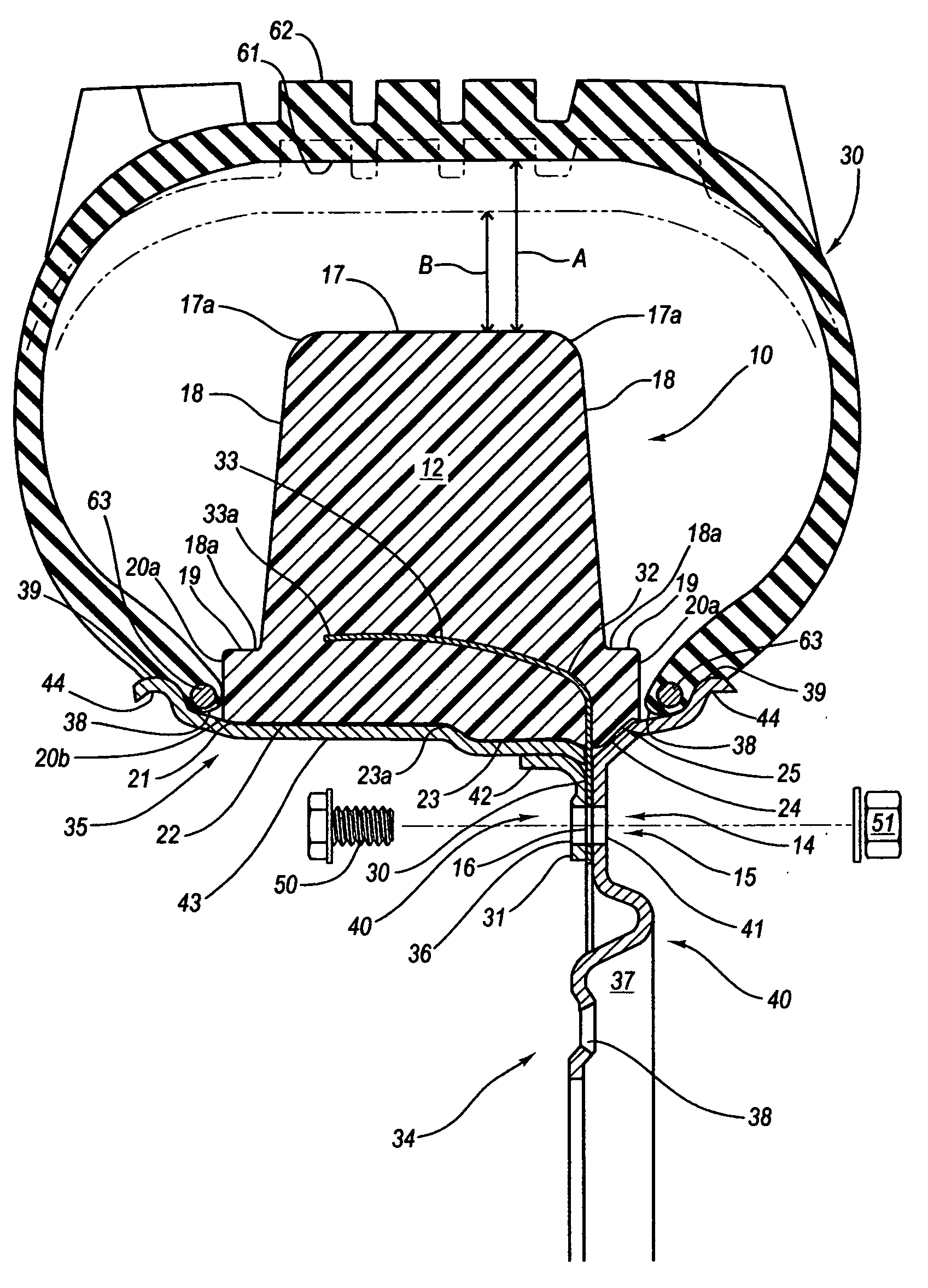

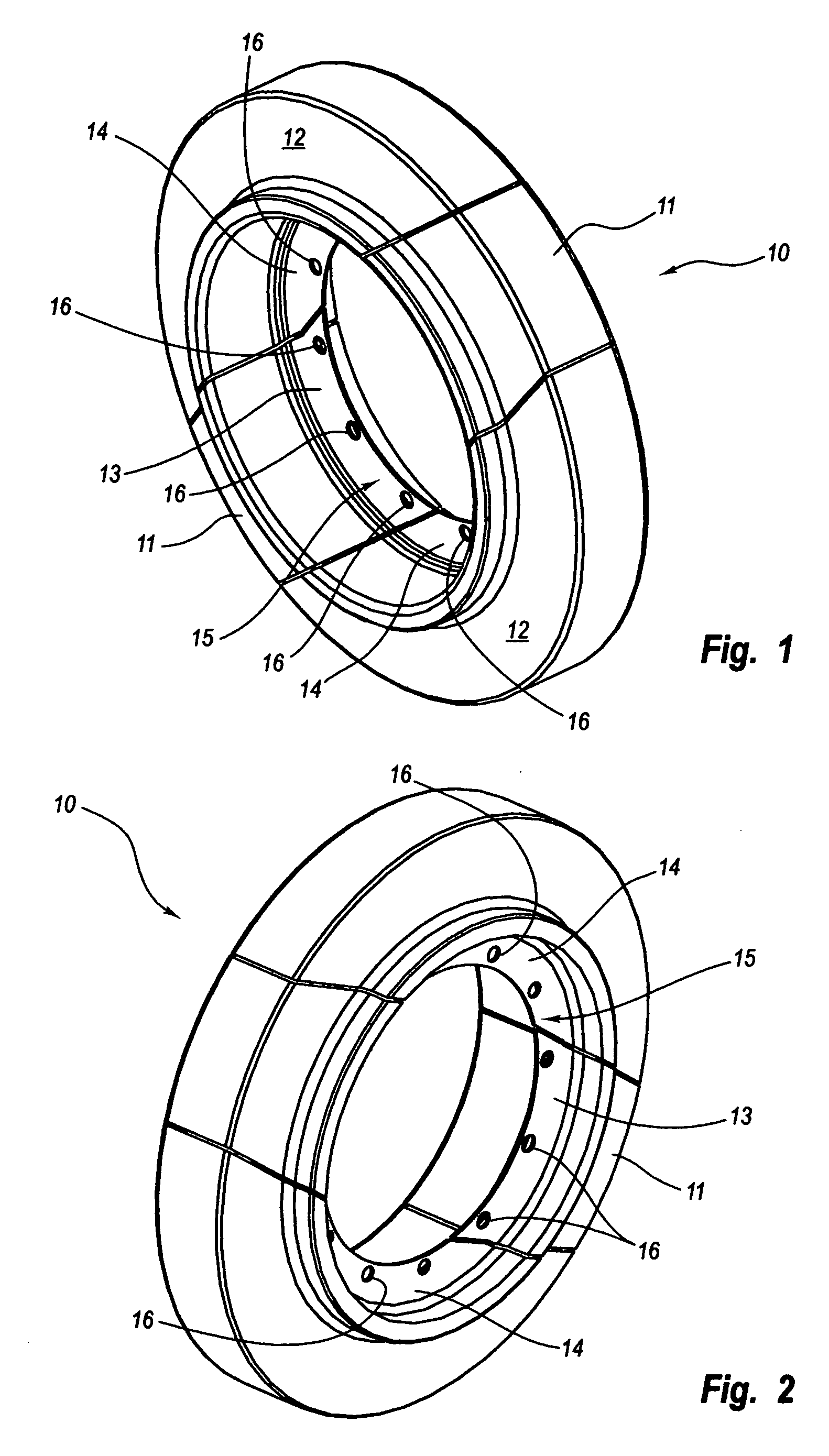

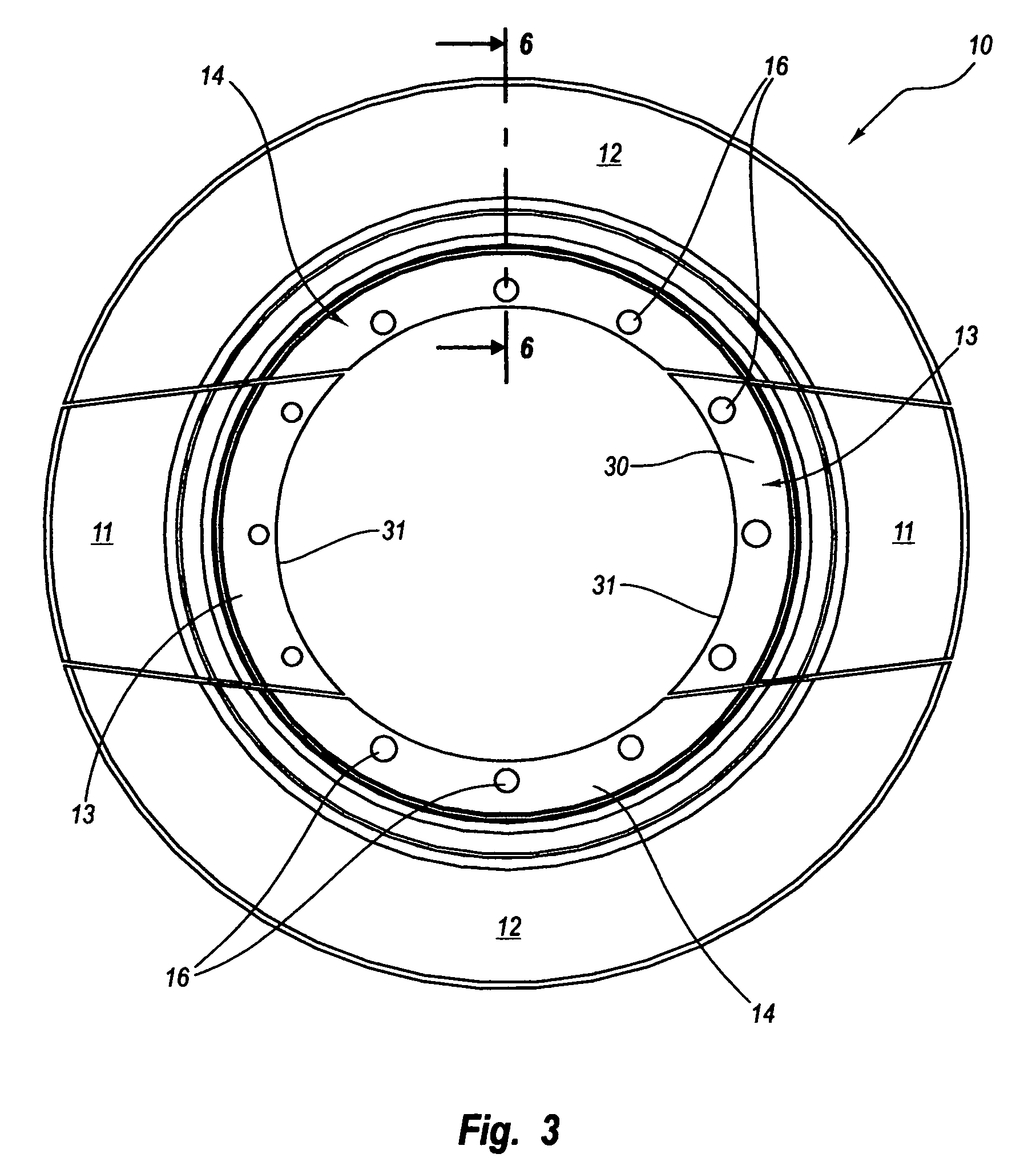

[0032] The invention is in a tire insert system that is shown assembled in FIGS. 1 and 2 into a tire insert ring 10 that is for assembly in a tire, that is mounted onto a wheel 34, as illustrated in FIG. 7. The tire insert ring 10 is shown in a profile perspective view, taken from the rear thereof, in FIG. 1, and as a profile perspective view, taken from the front thereof in FIG. 2. As shown, the tire insert ring 10 is formed from arcuate segments, and the Figs. show four separate arcuate segments as making up a complete insert ring 10. It should, however, be understood that as few as two arcuate segments are required to form the tire insert ring 10, and so a greater number than two arcuate segments could be so used to form the tire insert ring 10, within the scope of this disclosure.

[0033]FIGS. 1 and 2 show four tire insert segments that have been fitted together to form the tire insert ring 10. Which tire insert ring includes a first pair of insert segments 11 that are each of li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com