Hand grinder, flange for accomodating a grinding tool, and balancing unit

a technology for balancing units and power grinders, which is applied in the direction of manufacturing tools, mechanical equipment, and portable power-driven tools. it can solve problems such as annoyance to users, and achieve the effects of reducing vibration, balancing the working shaft and the grinding tool reliably, and reducing the vibration of the handheld power grinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

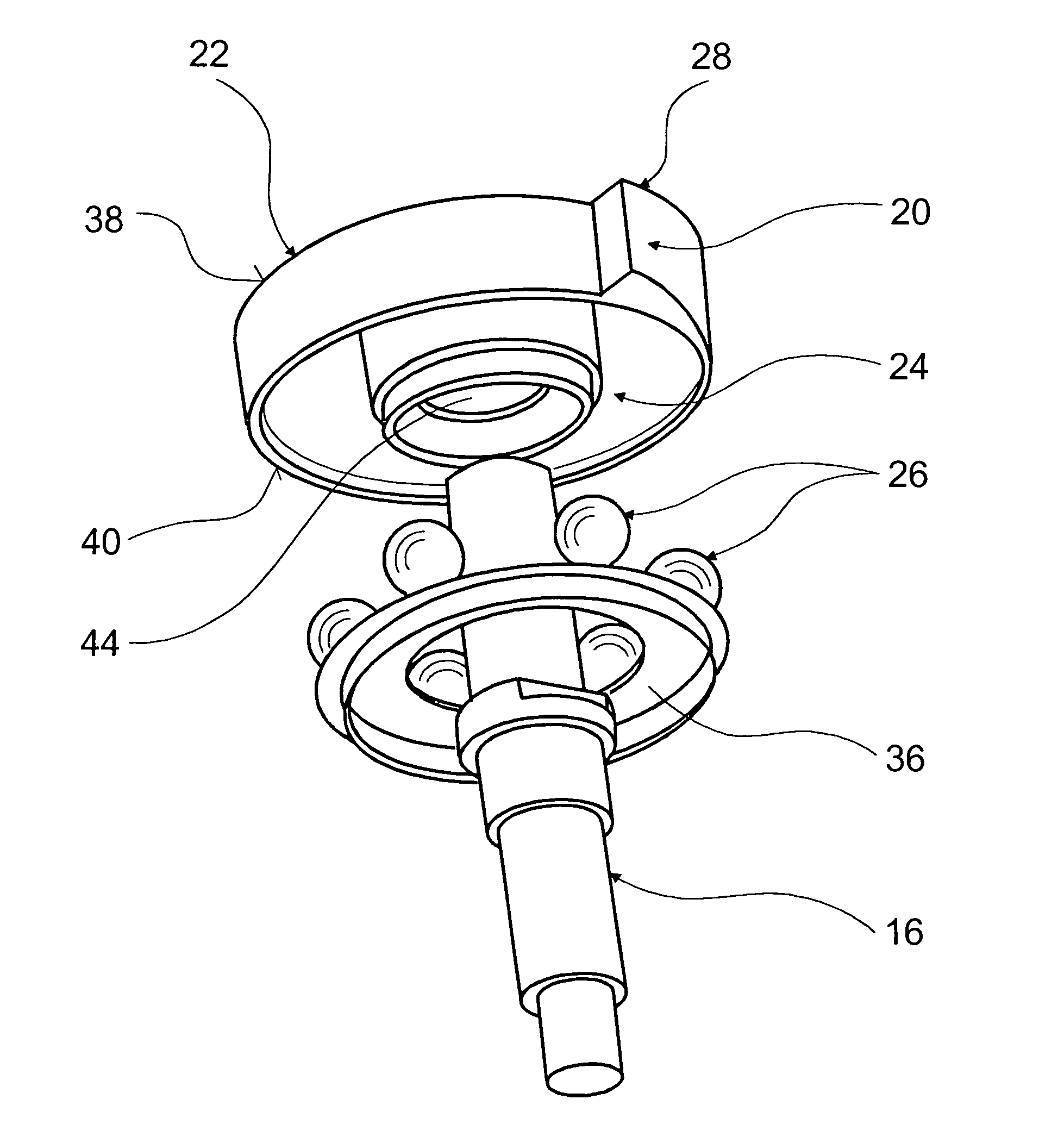

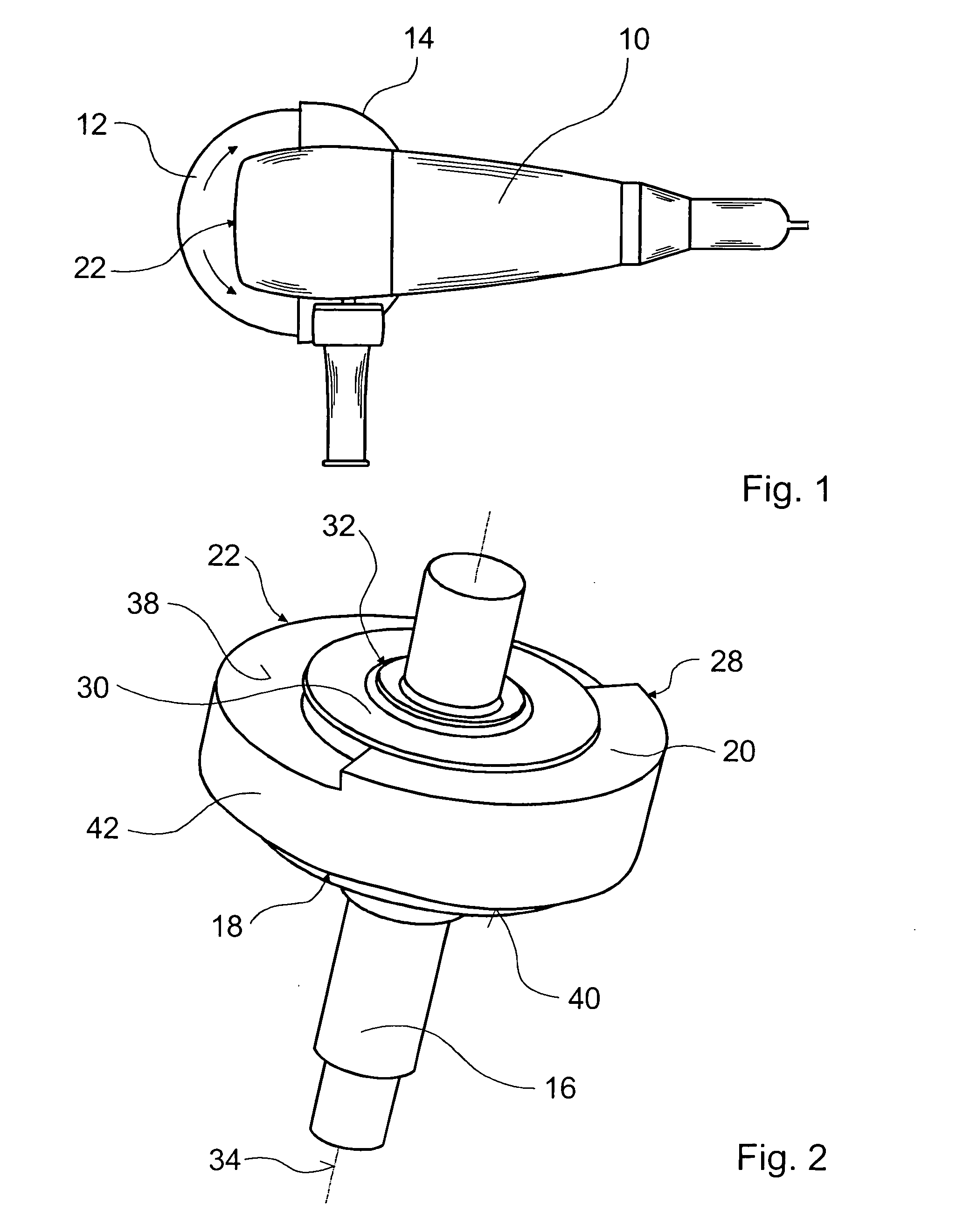

[0031]FIG. 1 shows a preferred handheld power grinder in a top view with a motor located in a housing 10, with a grinding tool 12 which is connected to a motor- driven working shaft, not shown, and with a balancing unit 22, which will be described in further detail in conjunction with the ensuing drawings. In the drawings, identical elements are identified by the same reference numerals throughout. The grinding tool 12, in this case a grinding wheel, may be covered with a guard hood 14, to protect a user from injuries.

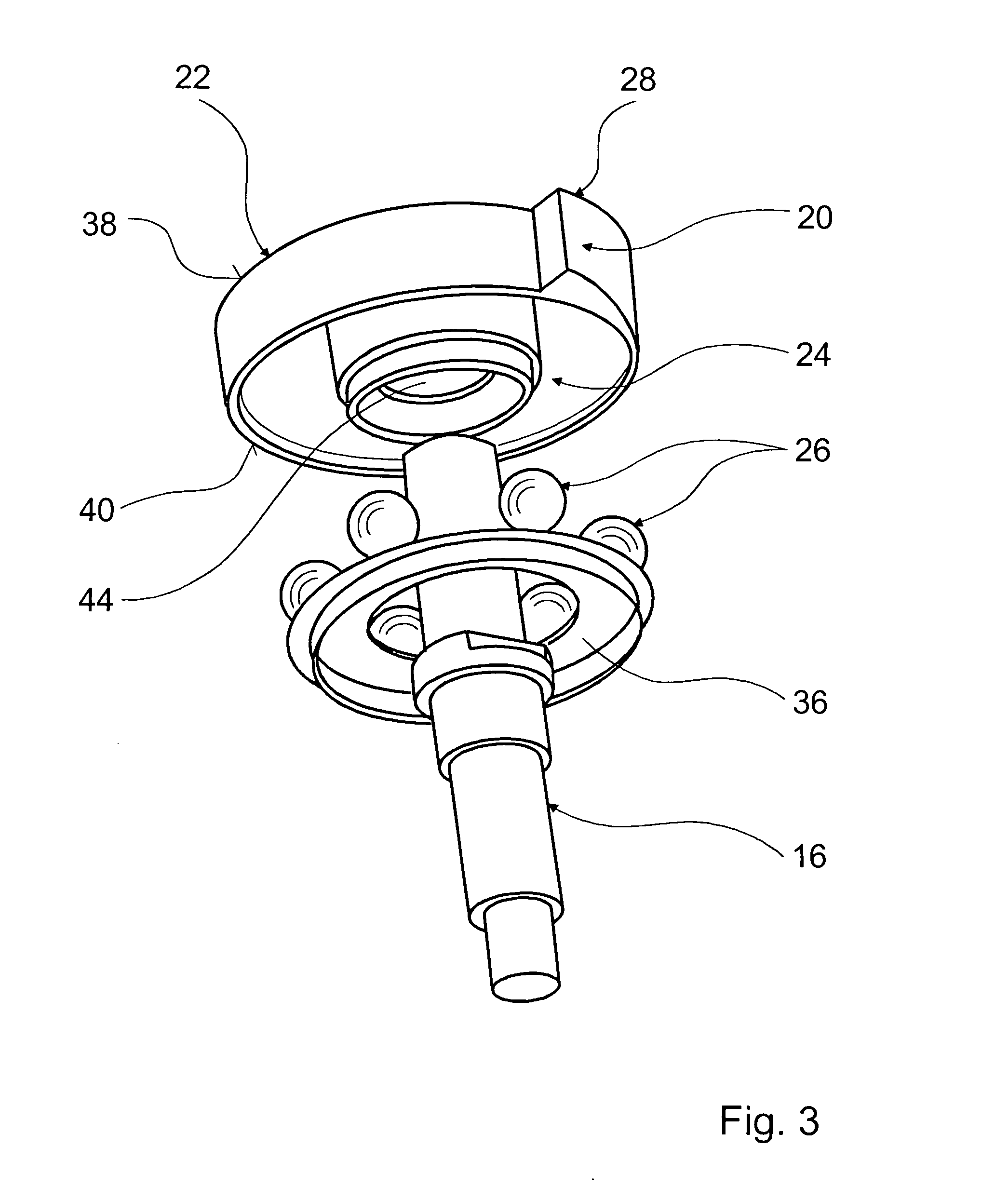

[0032] A detail of the arrangement of the balancing unit 22 is shown in FIG. 2. On a working shaft 16 which is driven by the motor, not shown, in particular an electric motor, the balancing unit 22 is seated concentrically with a receiving flange 30, which is integrated a front side 38 and has an eccentrically embodied grinding tool receptacle 32 for the grinding tool 12. The working shaft 16 rotates about the axis of rotation 34. The balancing unit 22 has both a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com