Hidden electric power elevating stand structure

a technology of electric power and hidden electric power, which is applied in the field of hidden electric power elevating stand structure, can solve the problems of not being able to fully adjust the horizontal attachment with the ceiling, not being able to fully adjust the horizontal attachment, and not being able to install the elevating stand easily, so as to facilitate its installation and maintenance, and beautify the overall external appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

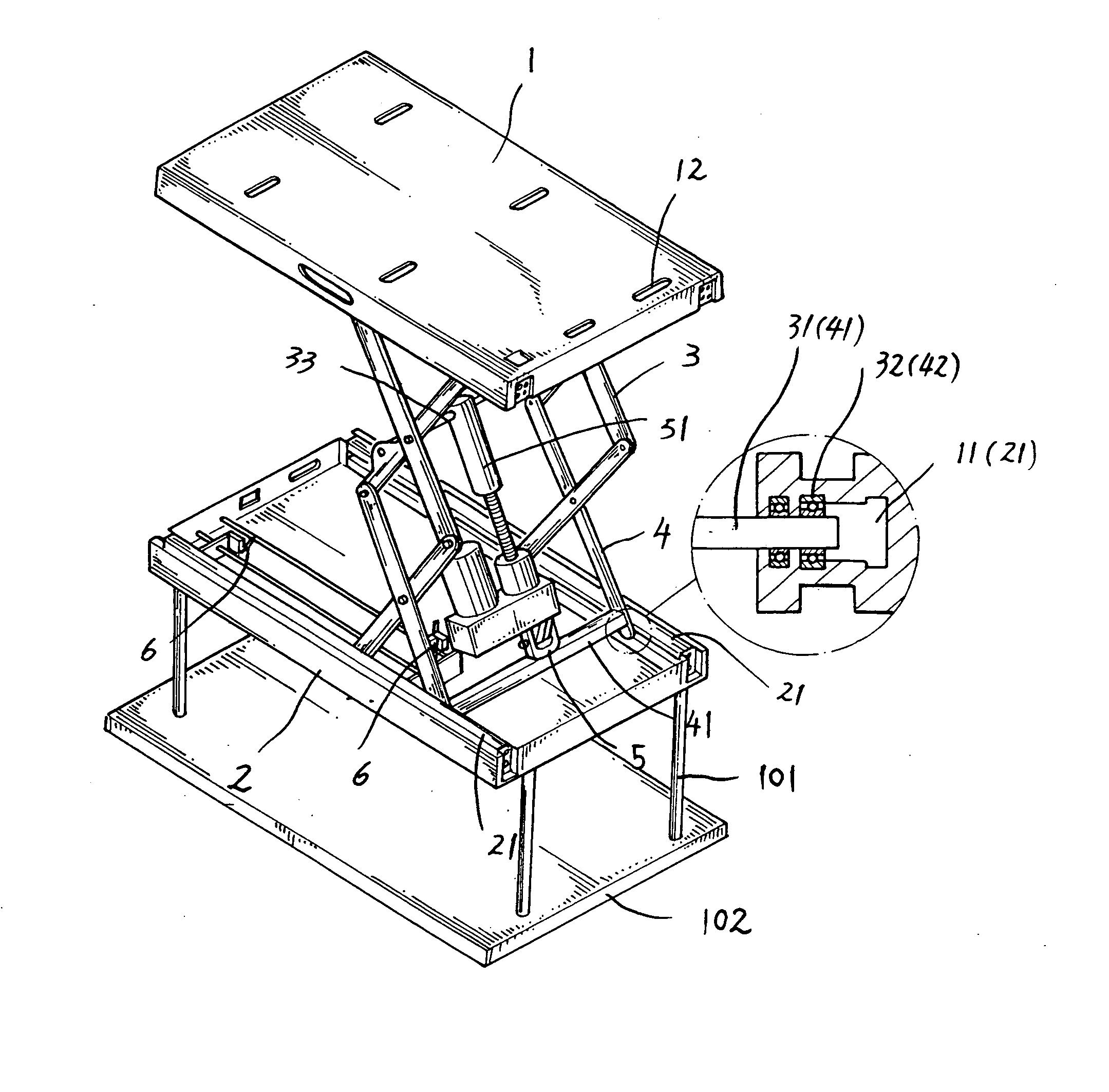

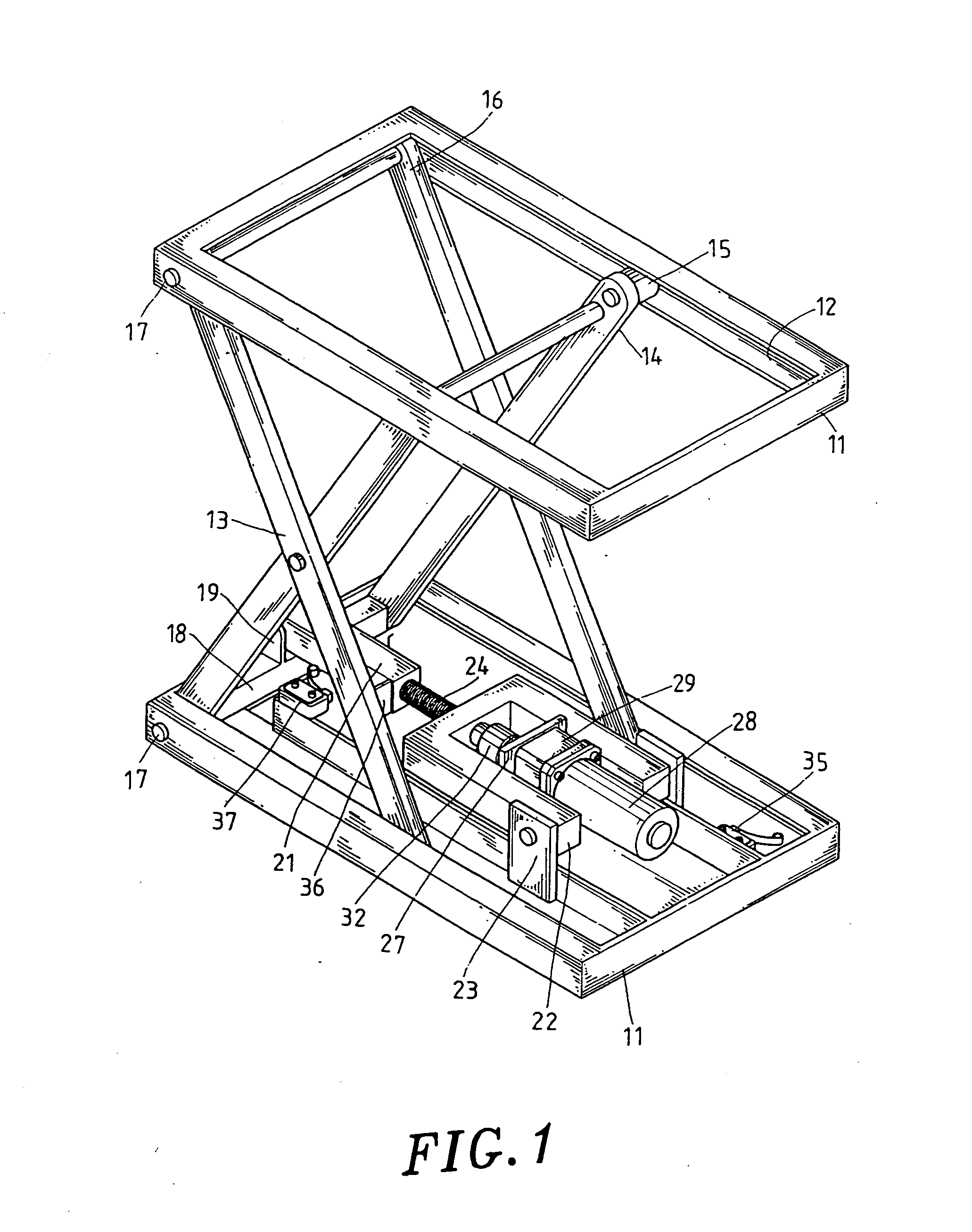

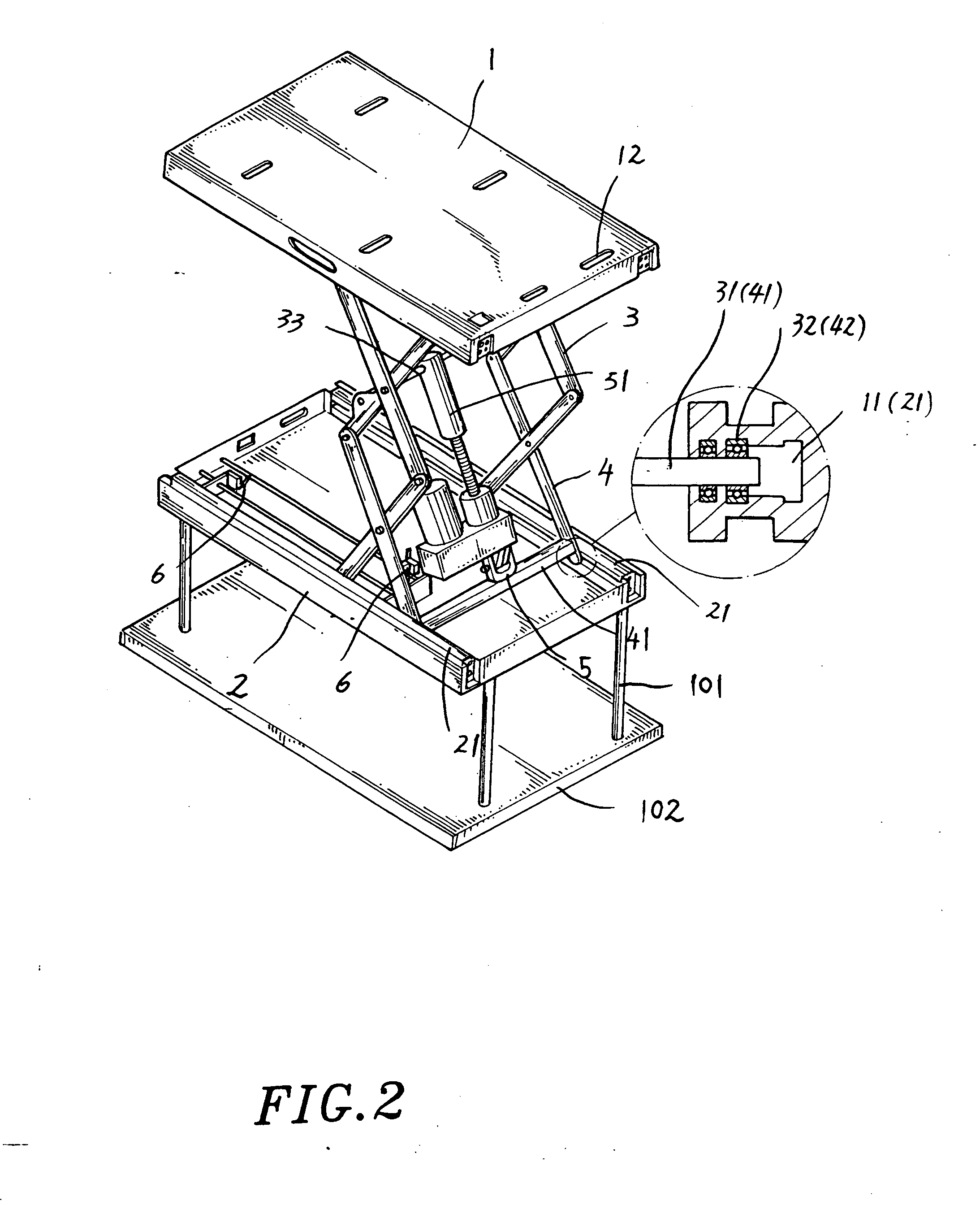

[0019] Referring to FIGS. 2 and 3, the present invention comprises upper and lower frame bodies 1, 2, a track disposed longitudinally along the lateral sides of the upper and lower frame bodies 1, 2 respectively, so that upper and lower braking rods 3, 4 crossed with each other are connected to the upper and lower frame bodies 1, 2; wherein transversal rods 31, 41 are disposed separately at the top of the upper braking rod 3 and the bottom of the lower braking rod 4, and bearings 32, 42 are disposed separately on both ends of the transversal rods 31, 41, such that the bearings 32, 42 are disposed in the tracks 11, 21 respectively and can slide along the tracks 11, 21.

[0020] The transversal rod 41 disposed at the bottom of the lower braking rod 4 is fixed to an electric screw rod 51 by a U-shape fixing plate 5, so that the front end of the screw rod 51 is connected to a transversal rod 33 disposed at the intersection of the upper braking rod 3. When the screw rod 51 is extended or w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com