Continuous molding of fastener products and the like and products produced thereby

a technology of fastener products and products, applied in the direction of filament/thread forming, layered products, other domestic articles, etc., can solve the problems of small separation between adjacent mold plates, undesirable variation in the thickness of the base layer across the width of the product, and limited bending resistance of the mold roll, so as to achieve uniform product thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

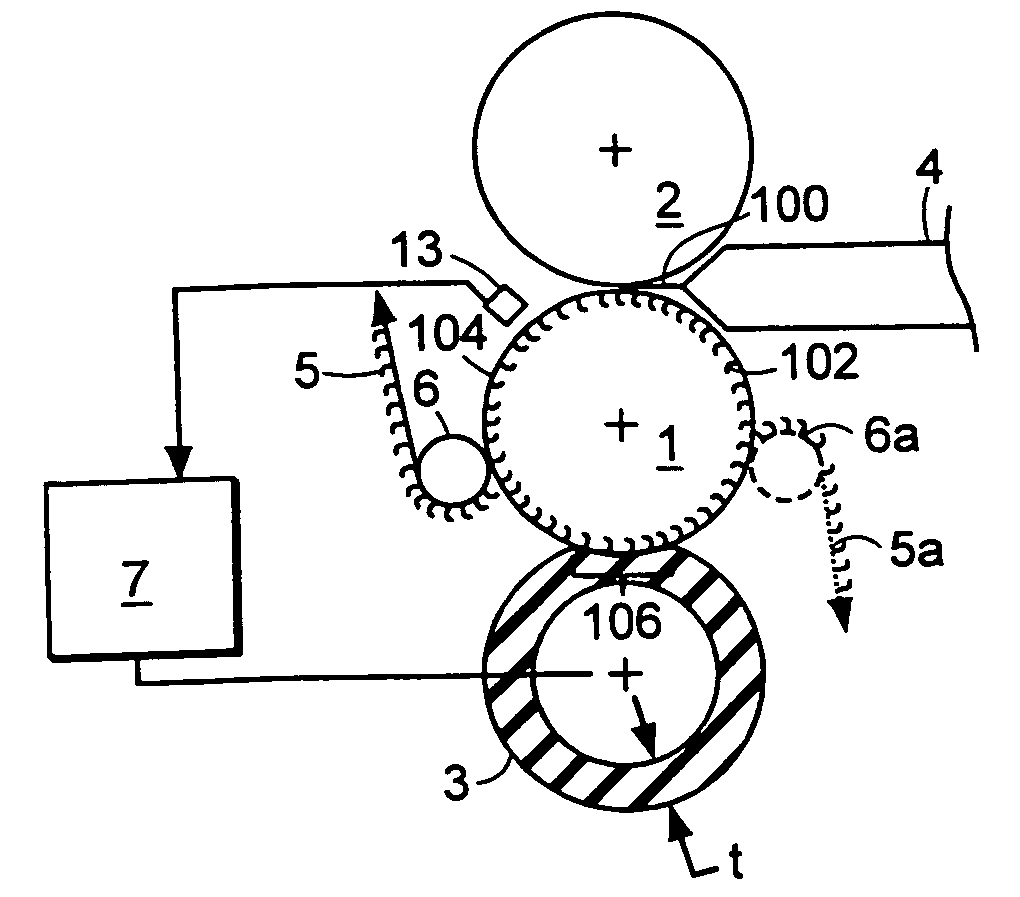

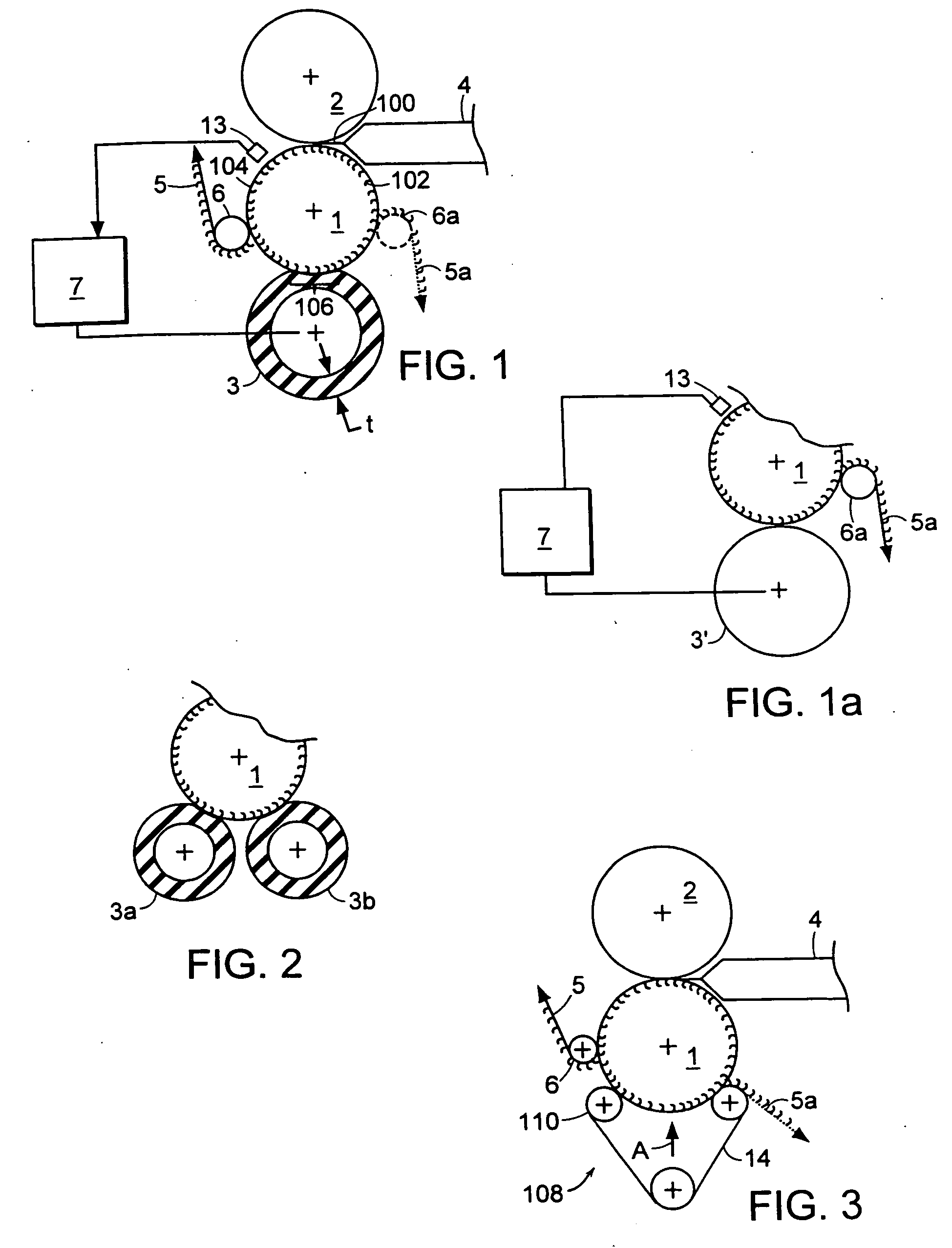

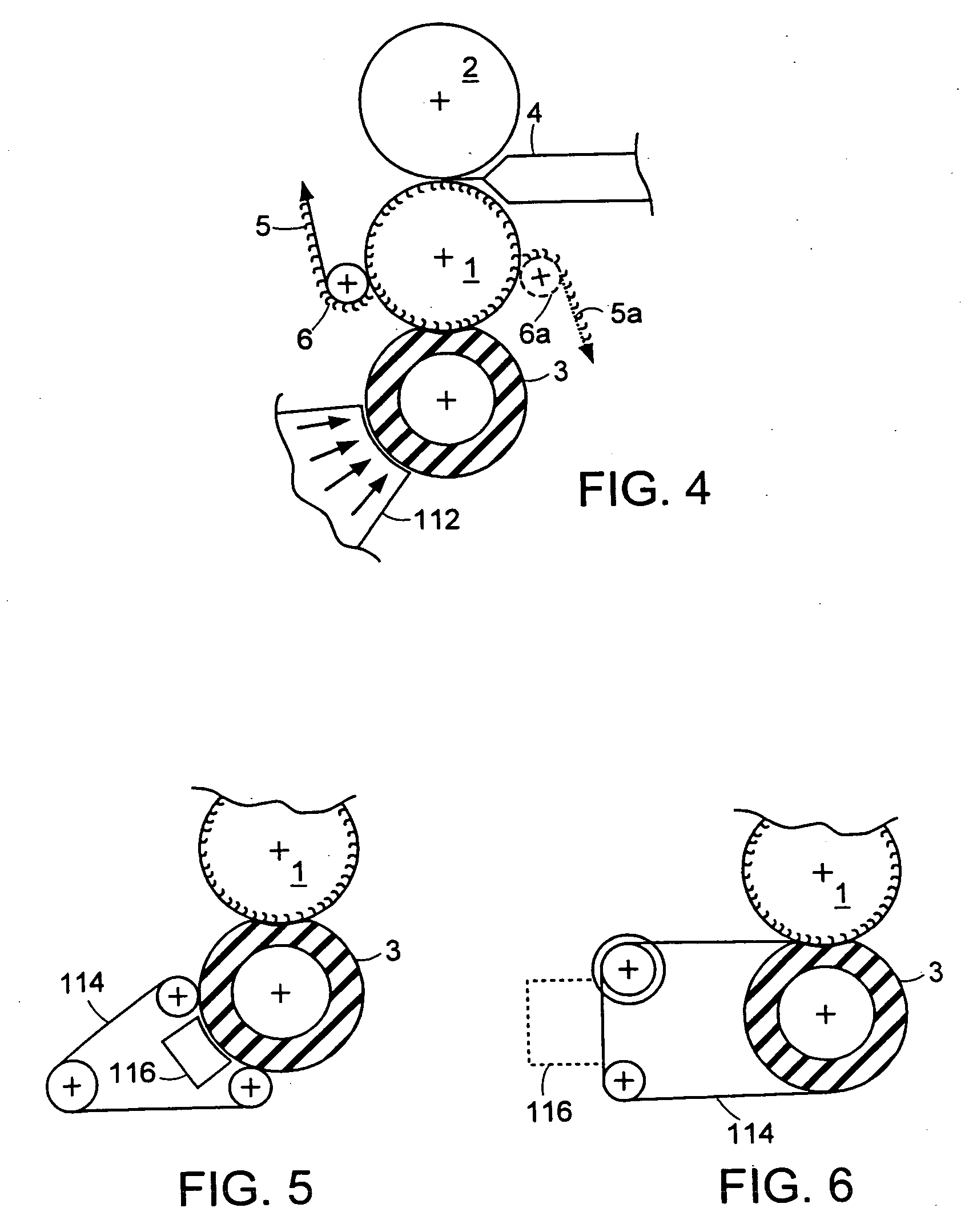

[0075] Referring to the embodiment of FIG. 1, an extruder 4 delivers a wide extrusion of molten polymer 100 into the nip (i.e. into the pressure zone) between an elongated mold roll 1 and a pressure roll 2. The polymer is forced into fastener-shaped cavities 102 by the pressure of the nip, forming a base layer with integral fastener elements. The fastener elements are, in some cases, fully-formed elements capable of snagging loops as molded. In other cases, the fastener elements are preform elements that are intended to be subjected to a post-forming operation to form completed fastener elements. The post-forming operation, in some cases, forms flat top portions on hook or post preforms. The fastener elements are very small to engage small loops or fibers on a surface, and typically are arranged on the web base with a density of 500 to 2,000 fastener elements per square inch.

[0076] The fastener product 5 is carried on the chilled mold roll 1 a distance sufficient to solidify the fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com