Multistage motor-compressor for the compression of a fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

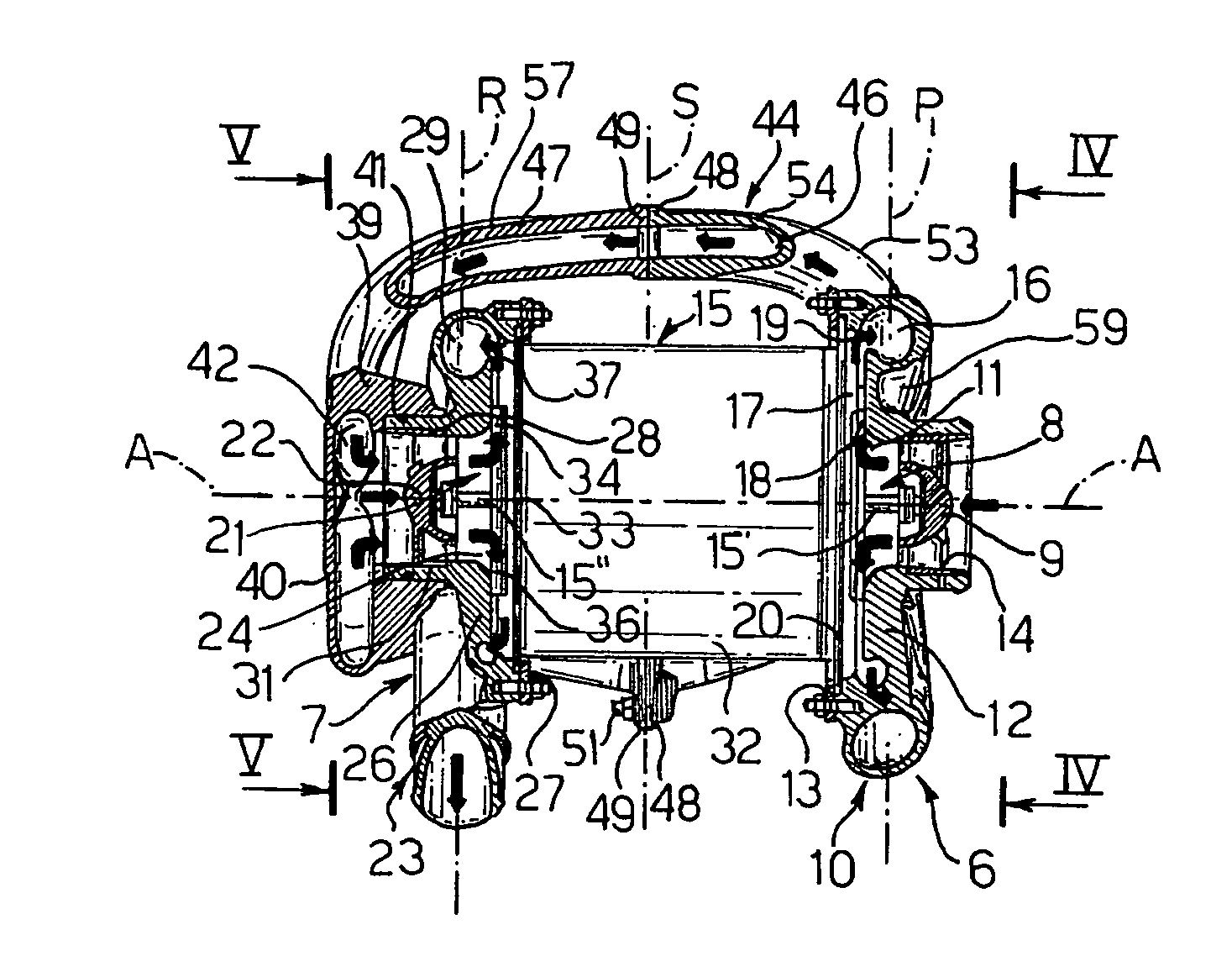

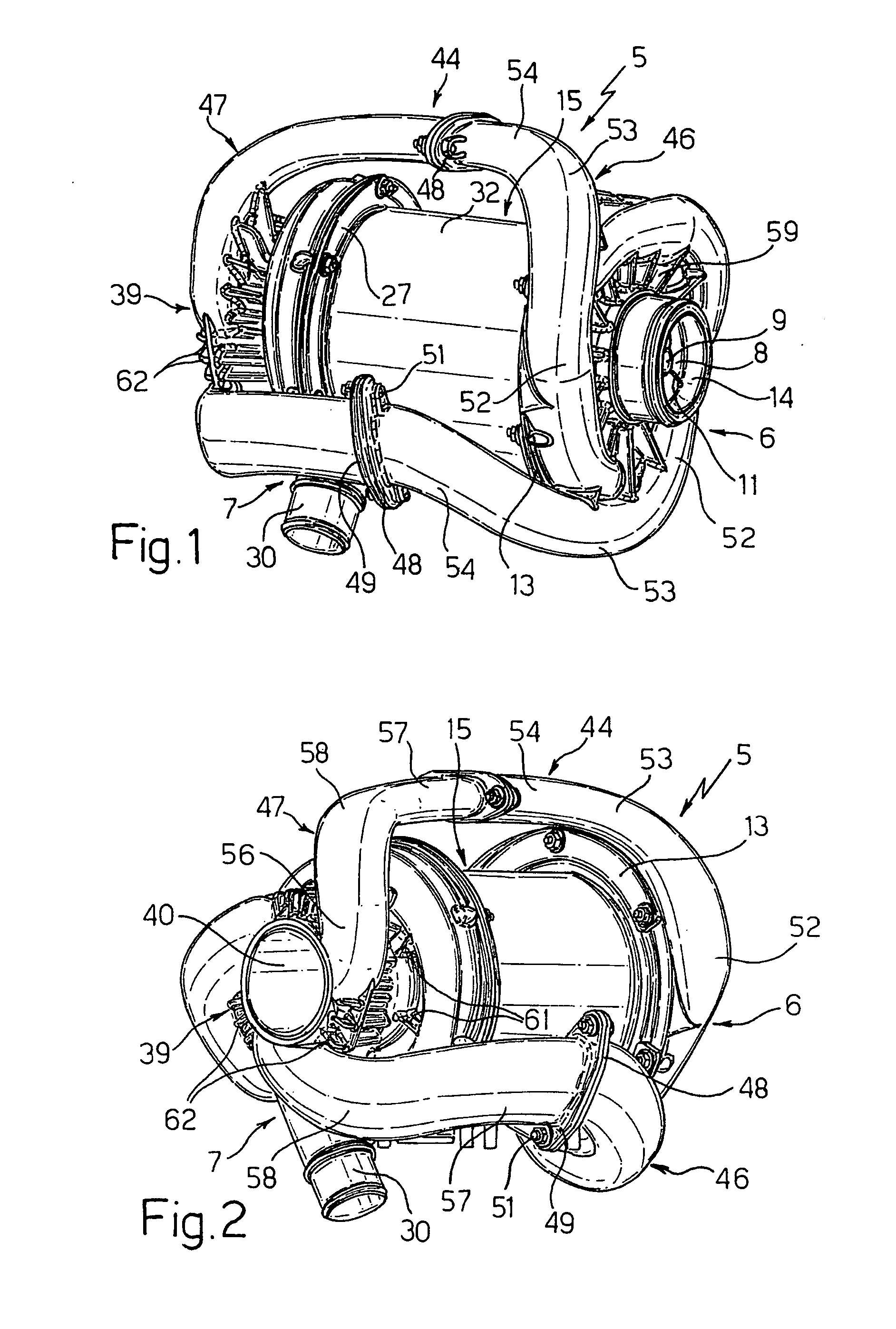

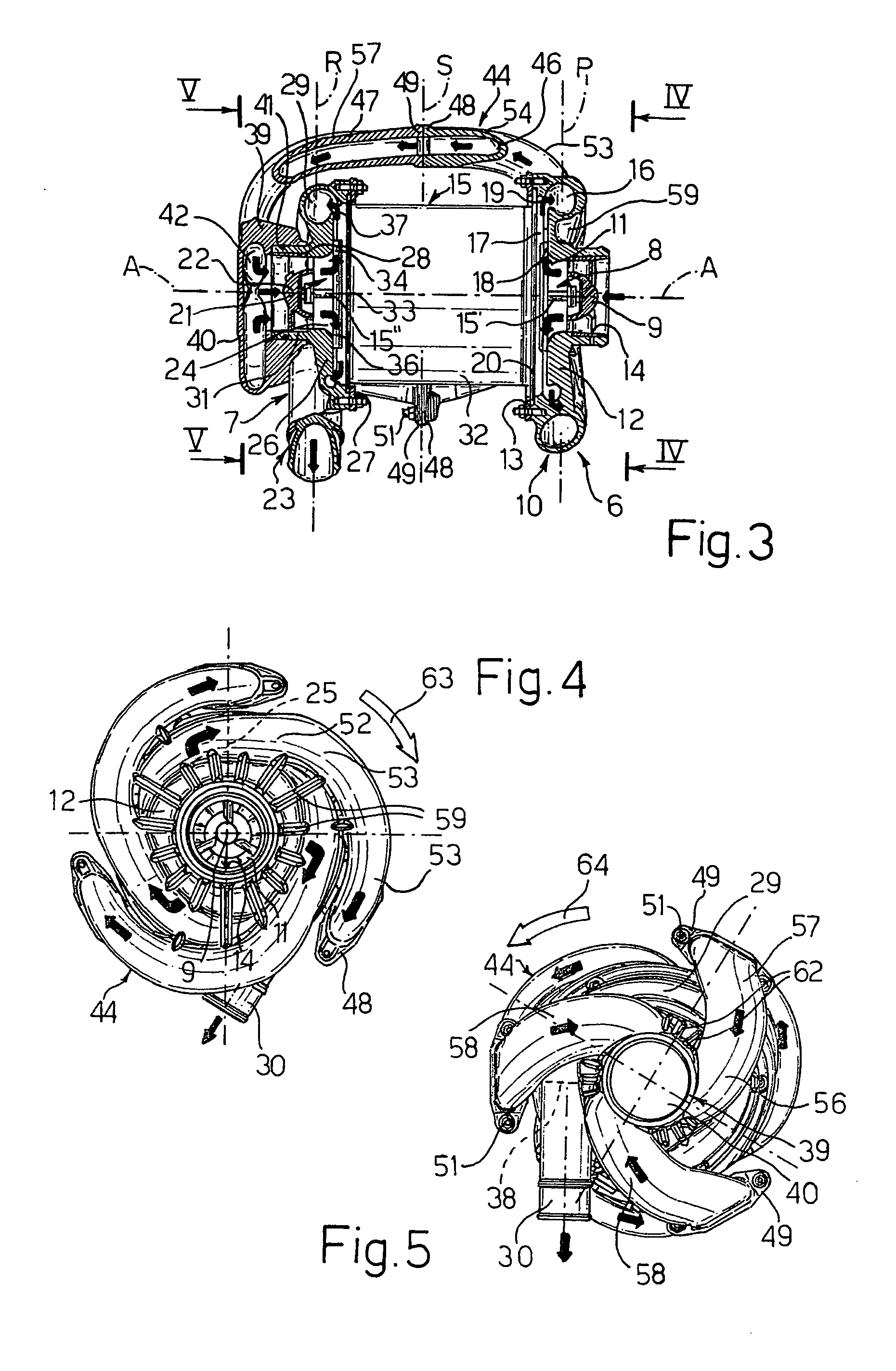

[0022] With reference to FIGS. 1 and 2, reference 5 generically indicates a multistage motor-compressor for the compression of a fluid, for motor vehicles for example. In particular, the motor-compressor 5 is of the type with two stages 6 and 7, low pressure and high pressure respectively, and is suitable for the supply of pressurized air in a fuel cell system or for supplying air to internal combustion engines, or for any system in which compressed air is required.

[0023] The low-pressure stage 6 comprises a low-pressure impeller, which henceforth will be called the primary impeller 8 (FIG. 3). The primary impeller 8 rotates around an axis A and is preceded by a fixed ogival portion 9, placed inside a low-pressure scroll, which henceforth will be called the primary scroll 10. The primary impeller 8 is fixed on one end 15′ of a shaft of an electric motor 15. The primary impeller 8 also comprises a series of substantially radial, shaped blades 11, of known type.

[0024] The primary sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com