Automated system for securing a load to a flatbed truck

a flatbed truck and automatic technology, applied in the field of trucking, can solve the problem that some truckers cannot tighten the straps for all loads in time, and achieve the effect of reducing the number of straps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

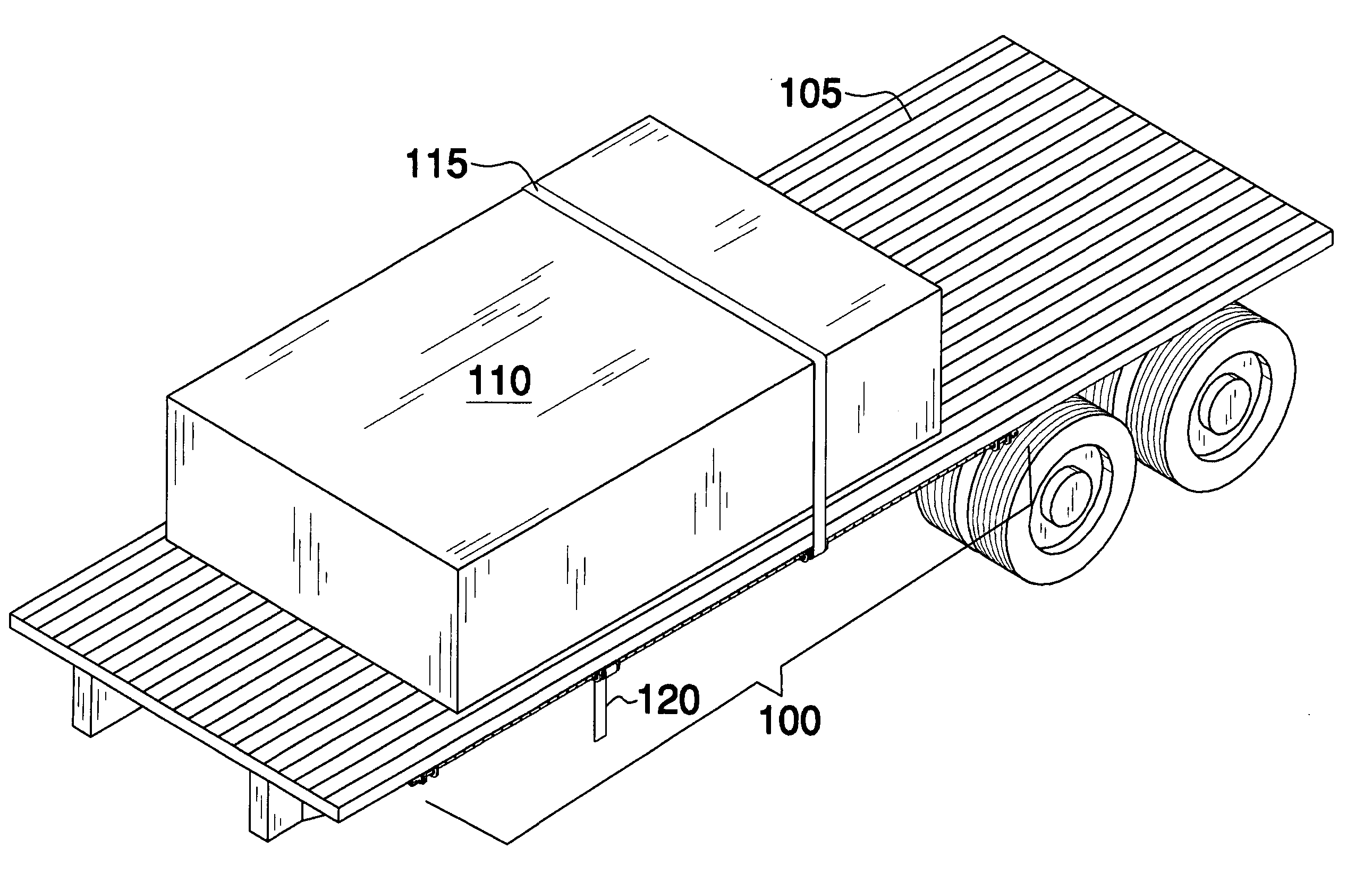

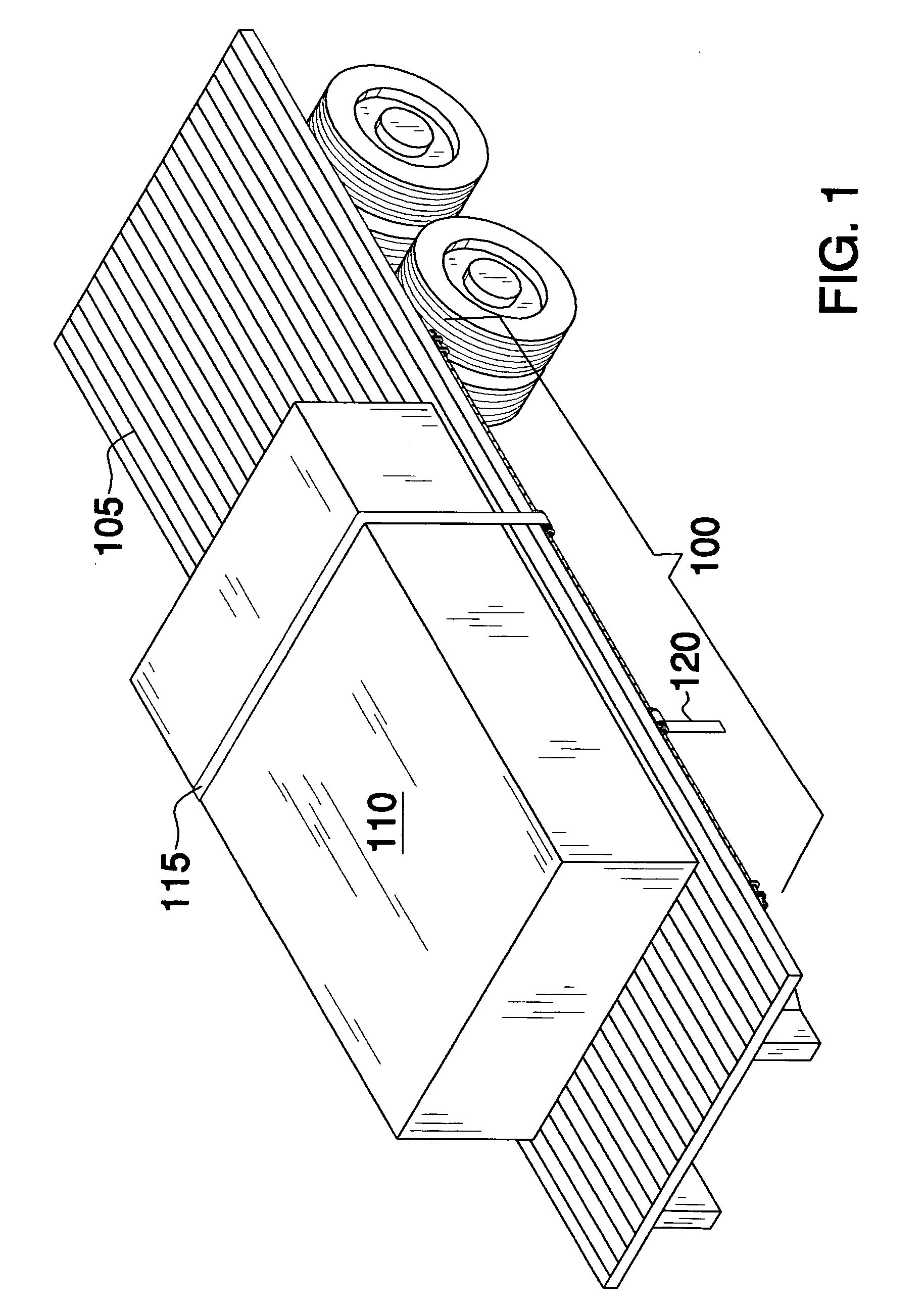

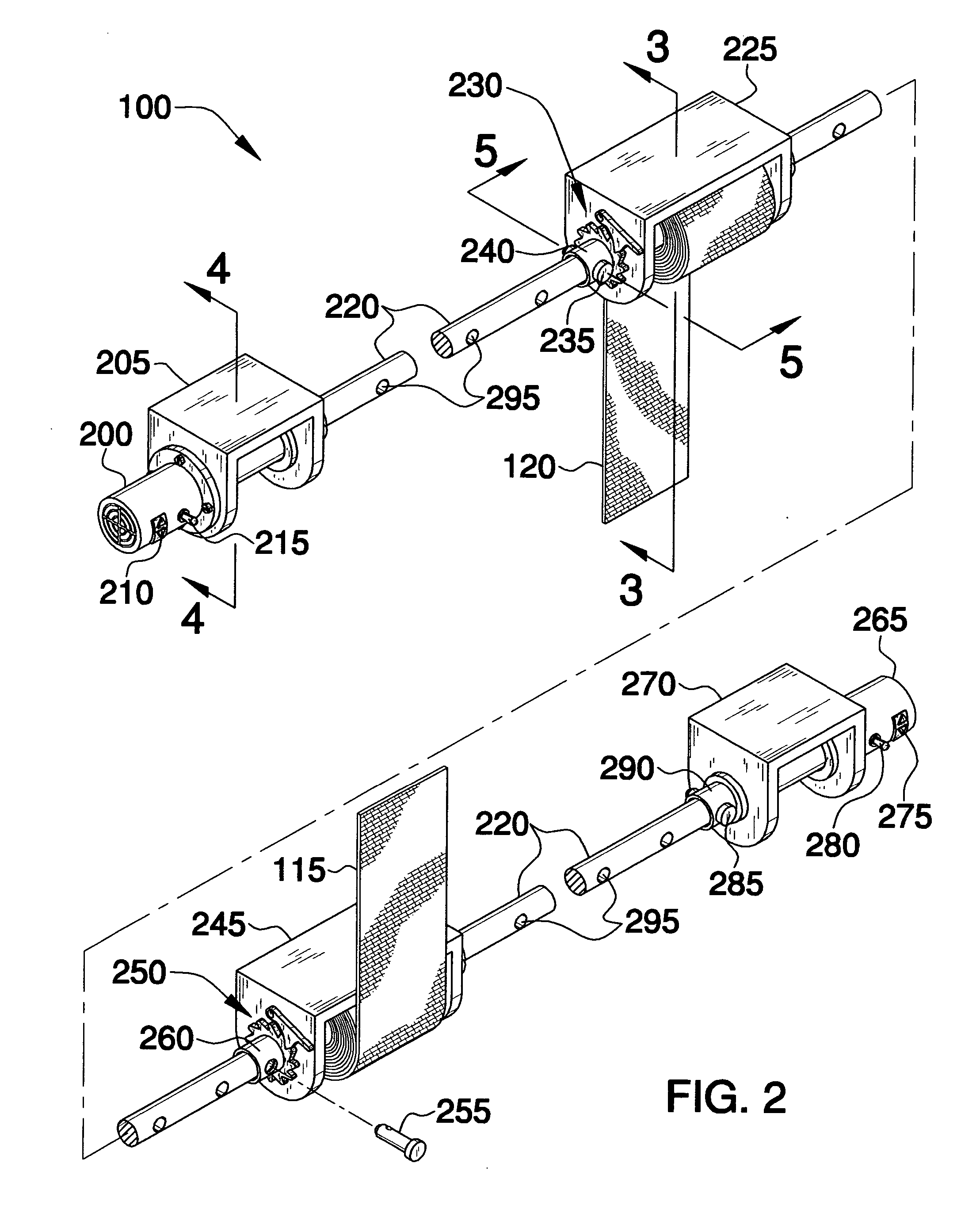

[0017]FIG. 1 shows the preferred embodiment 100 in its operational position, just below the edge of a flatbed trailer 105. The present system is designed to automate the load 110 securing process. The strapping down process is still primarily manual and requires that the tie down straps 115&120 be placed over the load 110 and attached to the opposite side of the trailer 105. The securing process requires a tightening of the tie down straps 115&120 so that each strap applies sufficient downward force on the load 110. For tall, heavy and awkwardly shaped loads the amount of downward force required to safely secure the load can be a tremendous amount, up to 1,000 lbs of pressure. Even using crow bars, some truckers are still not able to generate this much pressure. By using strong electric motors, the present system allows anyone to safely secure a load to a flatbed trailer. The preferred embodiment 100 can generate up to 1,200 lbs of pressure. The present system can also be retrofitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com