Sound modification system

a sound modification and sound technology, applied in the field of musical instruments, can solve the problems of limited system capabilities, need for intrusive mounting fixtures, and large dampening potential of drumheads, and achieve the effects of reducing or enhancing the decay characteristics of drumheads, facilitating the interchangeability of different types of sound altering elements, and facilitating movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

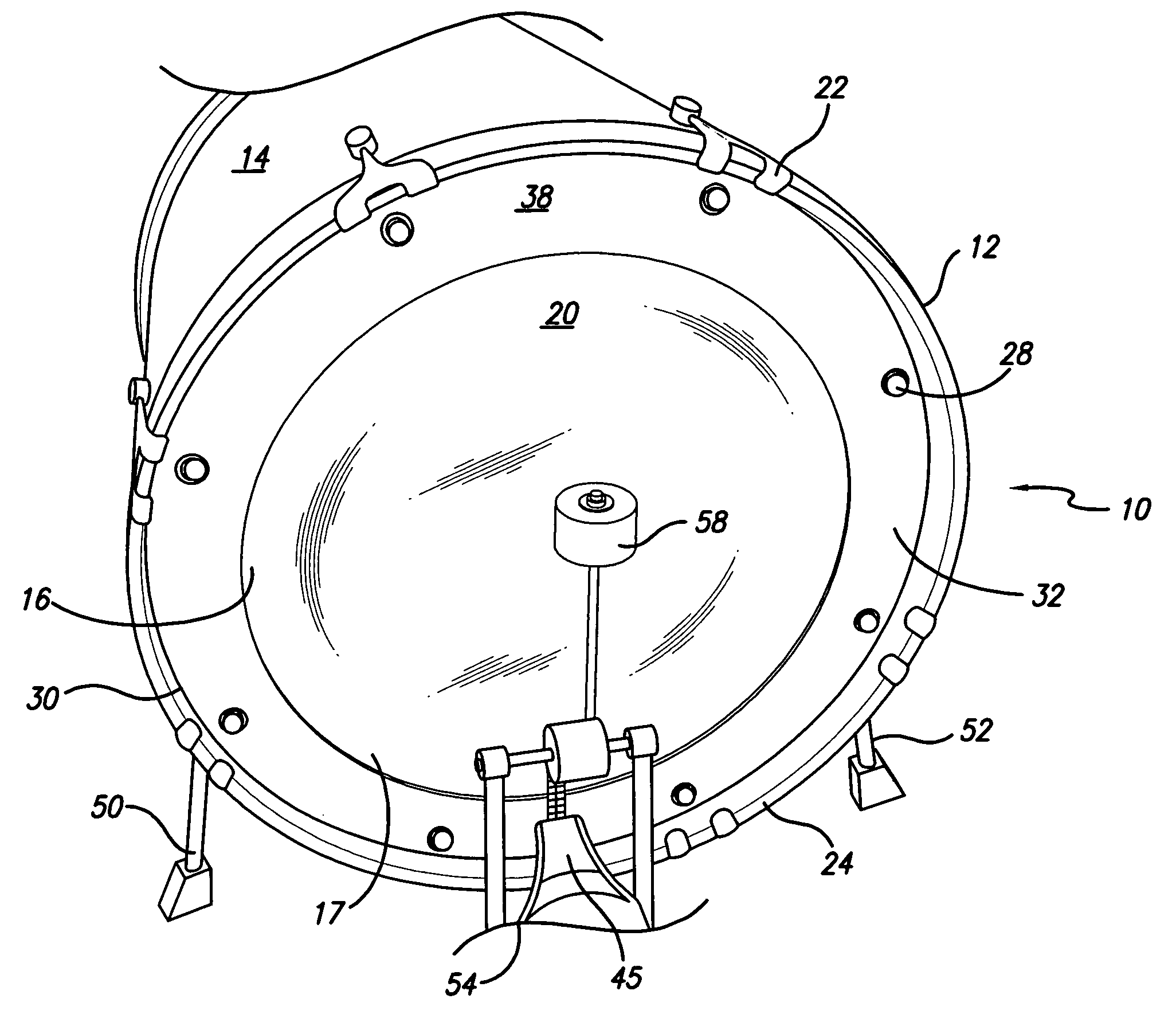

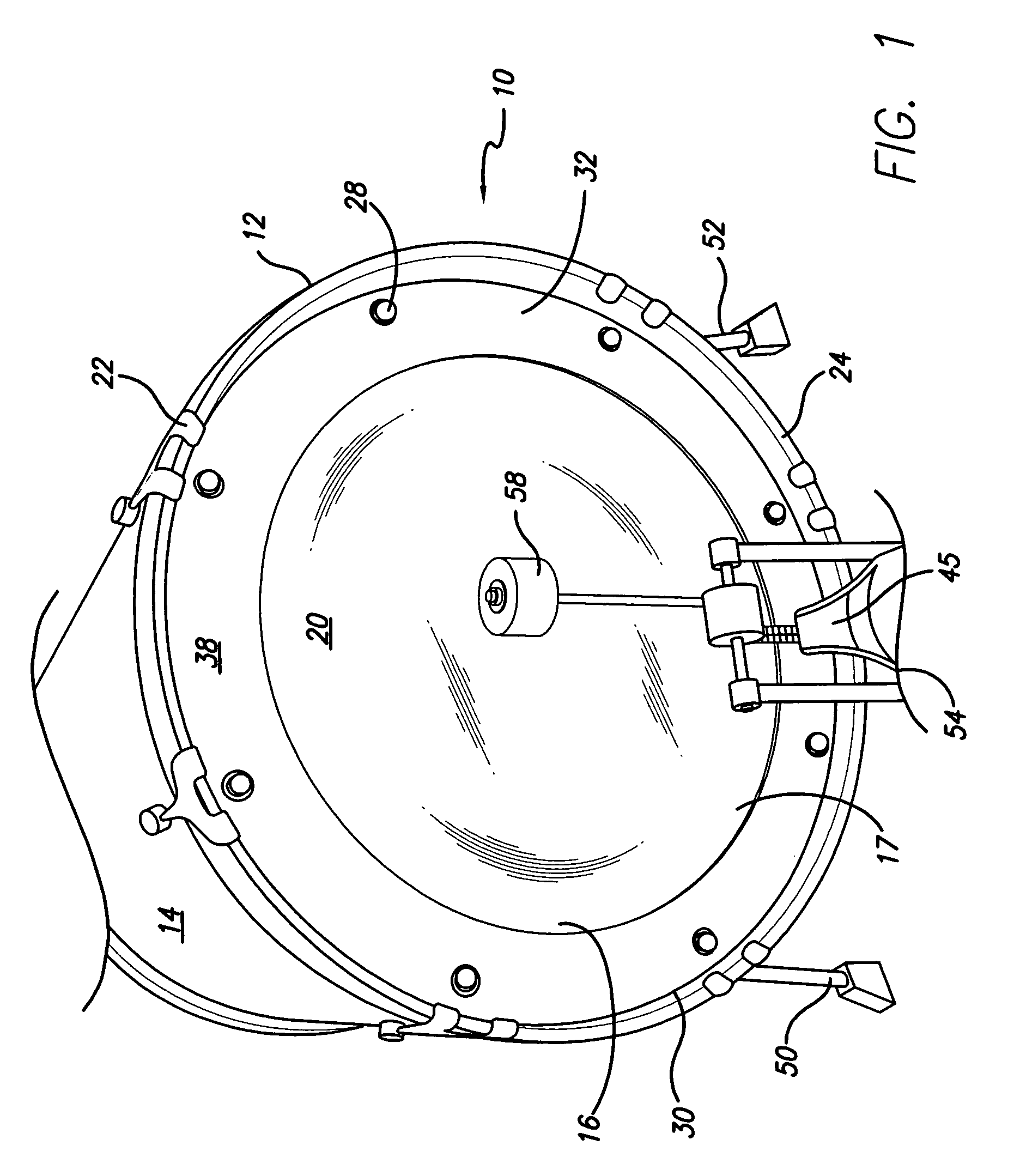

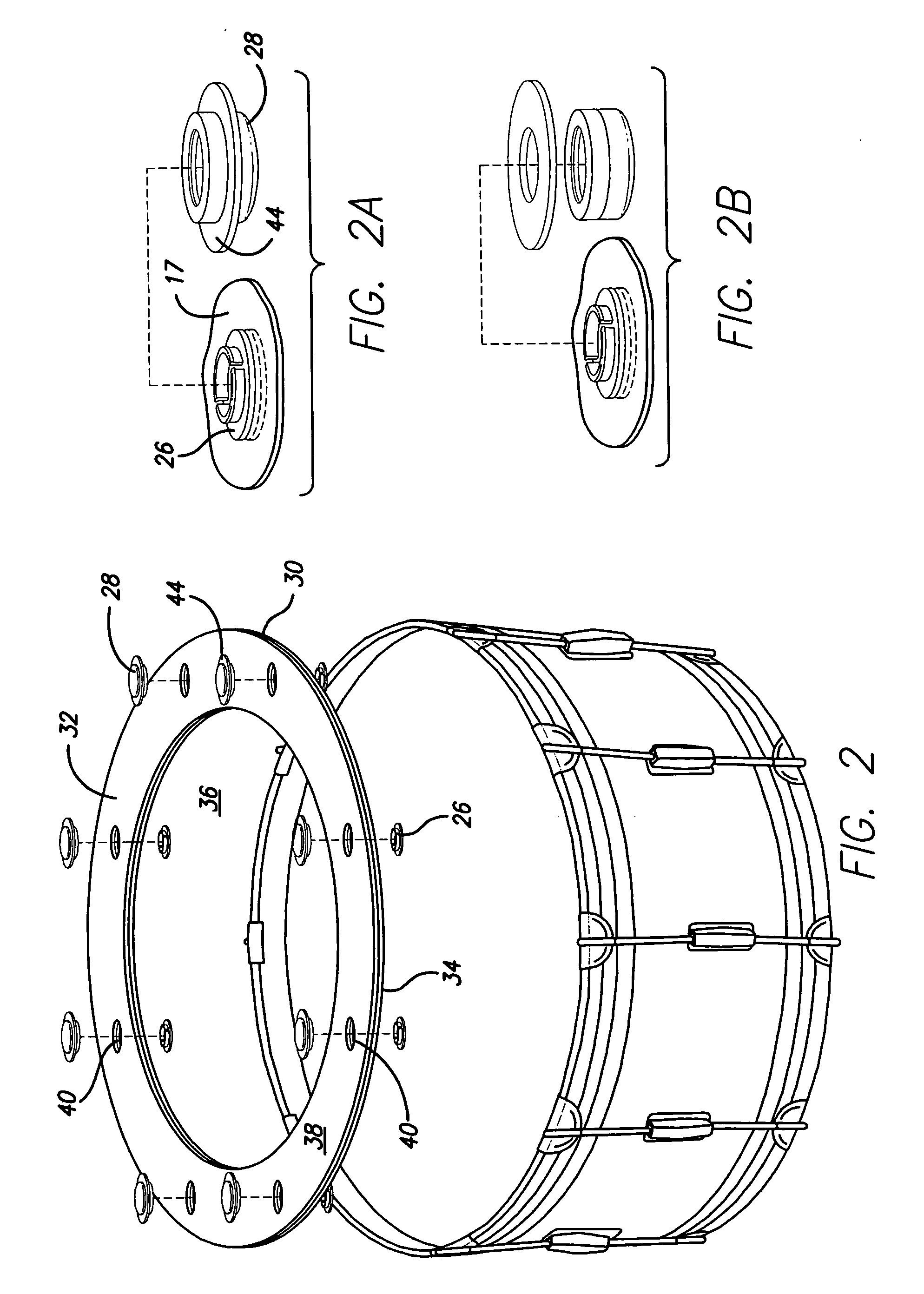

[0036] The preferred embodiment of the present invention, as shown in FIGS. 1 and 2, provides a sound modification system designated generally as 10 comprised of a bass drum 12 having a drum shell 14, a drumhead 16 with an inner surface 18 and a playing surface 20, and drum lugs 22 to tension drumhead 16 and secure hoop 24 to drumshell 14.

[0037] Snap fastener 26 (also referred to as a “socket”) is riveted or attached in any other suitable manner to playing surface 18. Matable with snap fastener 26 is snap fastener 28 (also referred to as a “button”). Fasteners 26 and 28 are typically made of a synthetic material, such as plastic, or any other suitably resilient material. Metal is also an alternative. Fastener 26, which begins as a rivet, is rolled over along its edges to effectively cinch and secure fastener 26 to drumhead membrane 17. Little or no air is lost (along the connection seam) as a result of this since fastener 26 is rolled and flared tightly against membrane 17. The ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com