Anode material for lithium ion batteries, preparation method and battery containing anode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of large BET, poor carbon surface modification effect, and inability to industrialize, etc., to achieve Effects that enhance fit and enhance finishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

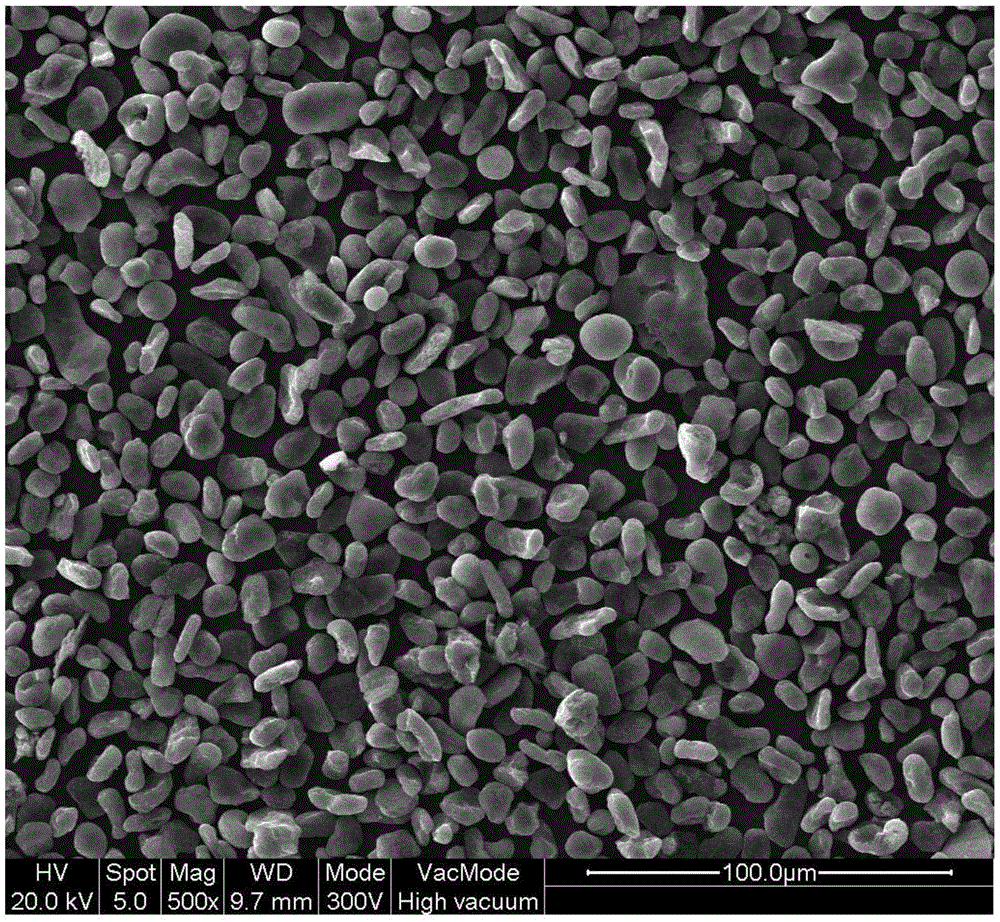

[0041] (1) Take 1Kg of silicon powder and use ethanol as the medium, wet-grind in a sand mill until the D50 particle size is 150nm, to obtain a silicon slurry containing 5wt% silicon;

[0042] (2) dissolving the polyvinyl butyral powder in ethanol to obtain a polyvinyl butyral resin alcohol solution with a concentration of 10 wt %;

[0043] (3) Take an appropriate amount of silicon slurry, resin alcohol solution, natural graphite with a particle size of 15 μm, and conductive carbon black, and the added amount is calculated according to the converted amount. Calculate the percentage of the total mass of the pure powder. After conversion, the addition ratio of silicon powder is 30wt%, the addition ratio of resin powder is 9wt%, the addition ratio of graphite powder is 60wt%, and the addition ratio of conductive agent powder is 1wt%, and then the mixed solution is stirred evenly , placed in a rotary evaporator to evaporate ethanol to obtain the precursor;

[0044] (4) Fully mix ...

Embodiment 2

[0051] (1) Take 1Kg of silicon powder and use ethanol as the medium, wet-grind in a sand mill until the D50 particle size is 100nm, to obtain a silicon slurry containing 10wt% silicon;

[0052] (2) dissolving the phenolic resin in ethanol to obtain a phenolic resin alcohol solution with a concentration of 30% by weight;

[0053] (3) Take appropriate amounts of silicon slurry, resin alcohol solution, natural graphite with a particle size of 9 μm, and nano-carbon fiber, and the added amount is calculated according to the converted amount. When converting, it is based on the four types of silicon powder, resin powder, natural graphite powder, and conductive agent. Calculate the percentage of the total mass of pure powder. After conversion, the addition ratio of silicon powder is 15%, the addition ratio of resin powder is 13%, the addition ratio of graphite powder is 70%, the addition ratio of conductive agent powder is 2%, and then the mixed solution is stirred evenly. Ethanol is...

Embodiment 3

[0059] (1) Take 1Kg of silicon powder and use ethanol as the medium, and wet-grind in a sand mill until the D50 particle size is 50nm to obtain a silicon slurry containing 15wt% silicon;

[0060] (2) dissolving the urea-formaldehyde resin in ethanol to obtain a urea-formaldehyde resin alcohol solution with a concentration of 20% by weight;

[0061] (3) Take appropriate amounts of silicon slurry, resin alcohol solution, natural graphite with a particle size of 6 μm, and nano-carbon fiber, and the amount added is calculated according to the converted amount. When converting, it is based on the four types of silicon powder, resin powder, natural graphite powder, and conductive agent. Calculate the percentage of the total mass of pure powder. After conversion, the proportion of silicon powder is 10%, the proportion of resin powder is 7%, the proportion of graphite powder is 80%, the proportion of conductive agent powder is 3%, and then the mixed solution is stirred evenly. Ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com