High-strength adhesive for a corrugated paperboard, and preparation method thereof

A corrugated board and adhesive technology, applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

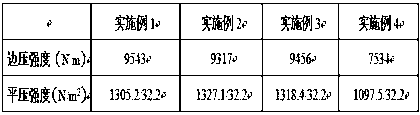

Examples

Embodiment 1

[0020] A high-strength adhesive for corrugated cardboard, the raw materials include in parts by weight: 30 parts of modified starch, 3 parts of polyvinyl alcohol, 2 parts of vinyl acetate, 0.5 part of acrylic acid, 0.8 part of stabilizer, 0.3 part of mineral oil, 1 part of acrylamide, 2 parts of isocyanate, 1.2 parts of CP-88 water repellent agent, 2 parts of cellulose, 1 part of polylactic acid, 0.8 part of agar.

[0021] Wherein, the modified starch is obtained by adding an oxidizing agent to modify the starch after acid hydrolysis, and the oxidizing agent is ammonium persulfate. The isocyanate is MDI. The cellulose is hydroxyethyl cellulose. Described stabilizing agent is polyethylene glycol.

[0022] The preparation method of the above-mentioned high-strength adhesive for corrugated cardboard comprises the following steps:

[0023] Step 1, adding starch to 1-2 times by weight of 20% hydrochloric acid solution, heating to 50°C for 40 minutes, adding an oxidant after cool...

Embodiment 2

[0028] A high-strength adhesive for corrugated cardboard, the raw materials include in parts by weight: 34 parts of modified starch, 4 parts of polyvinyl alcohol, 3 parts of vinyl acetate, 1.1 parts of acrylic acid, 1.3 parts of stabilizer, 0.7 parts of mineral oil, 2 parts of acrylamide, 2.4 parts of isocyanate, 1.7 parts of CP-88 water repellent agent, 3 parts of cellulose, 1.6 parts of polylactic acid, 1.2 parts of agar.

[0029] Wherein, the modified starch is obtained by adding an oxidizing agent to modify the starch after acid hydrolysis, and the oxidizing agent is potassium persulfate. The isocyanate is HDI. The cellulose is hydroxypropyl cellulose. The stabilizer is sodium alginate.

[0030] The preparation method of the above-mentioned high-strength adhesive for corrugated cardboard comprises the following steps:

[0031] Step 1, adding starch to 1-2 times by weight of 20% hydrochloric acid solution, heating to 50°C for 40 minutes, adding an oxidant after cooling, ...

Embodiment 3

[0036] A high-strength adhesive for corrugated cardboard, the raw materials include in parts by weight: 40 parts of modified starch, 5 parts of polyvinyl alcohol, 4 parts of vinyl acetate, 1.7 parts of acrylic acid, 1.5 parts of stabilizer, 0.9 parts of mineral oil, 4 parts of acrylamide, 3 parts of isocyanate, 2 parts of CP-88 water repellent agent, 4 parts of cellulose, 3 parts of polylactic acid, 1.5 parts of agar.

[0037] Wherein, the modified starch is obtained by adding an oxidizing agent to modify the starch after acid hydrolysis, and the oxidizing agent is sodium persulfate. The isocyanate is TDI. The cellulose is carboxymethyl cellulose. The stabilizer is gum arabic.

[0038] The preparation method of the above-mentioned high-strength adhesive for corrugated cardboard comprises the following steps:

[0039] Step 1, adding starch to 1-2 times the weight of 20% hydrochloric acid solution, heating to 60°C for 30 minutes, adding an oxidizing agent after cooling, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com