Golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

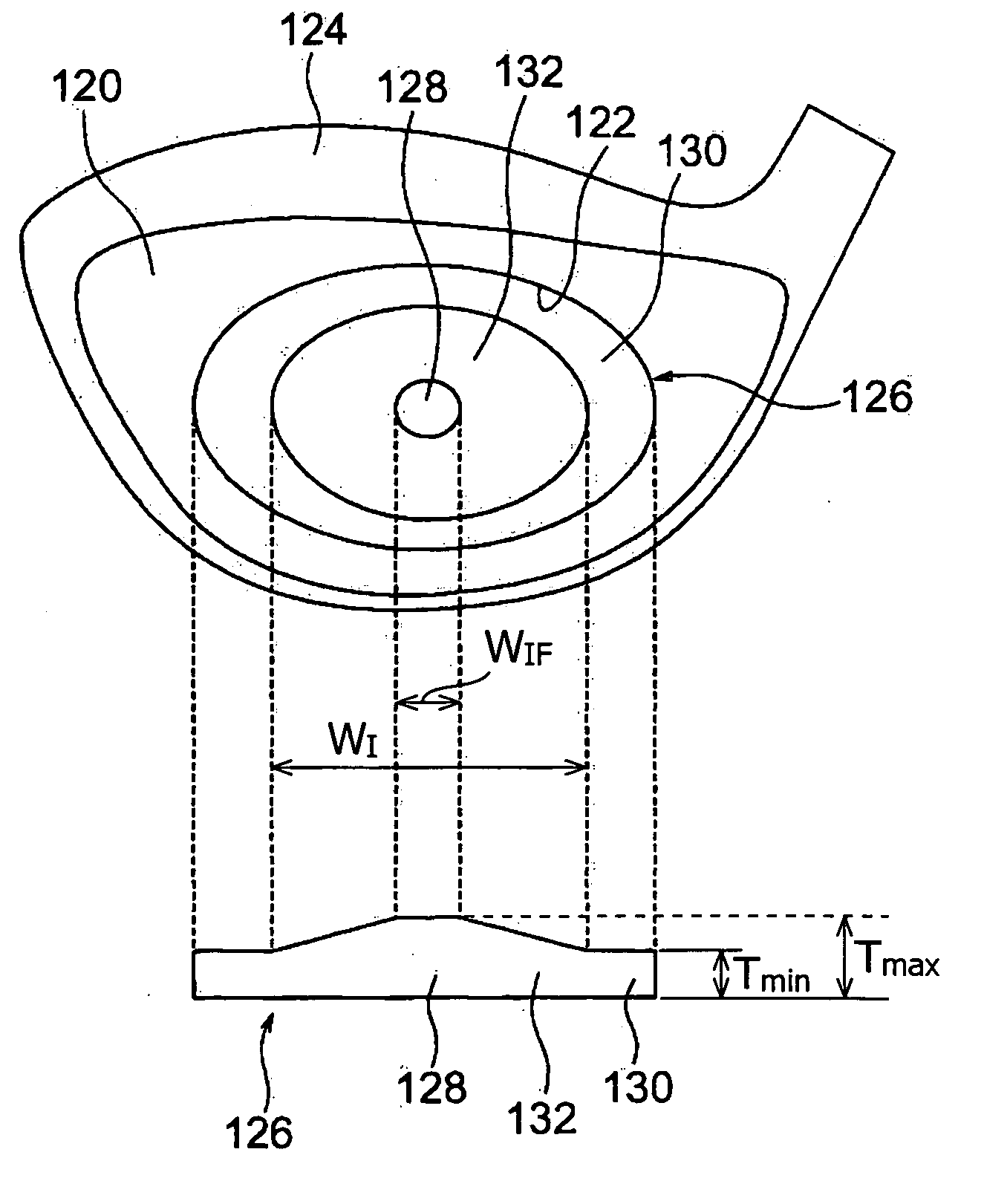

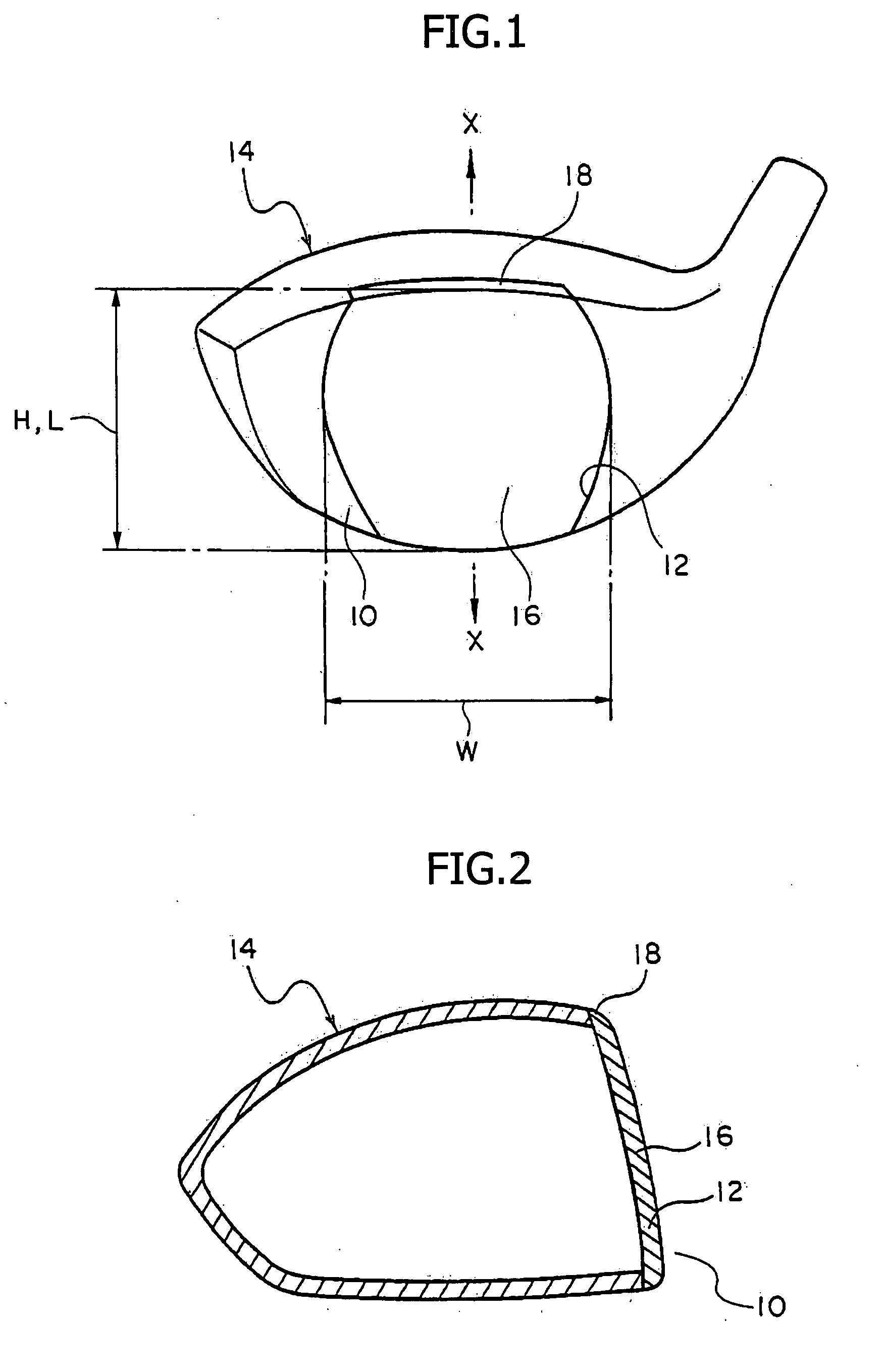

[0056]FIG. 1 is a perspective view showing an example of the club head according to the present invention. FIG. 2 is a cross-sectional view of the club head along the arrow line X-X in FIG. 1, and FIG. 3 is a perspective view of the face member of the club head. The club head of this embodiment is formed into a wood having an internal cavity.

[0057] The club head of this example comprises a head body 14 made of a titanium alloy (specifically, 6-4 Ti cast material), and a face member 16 made of a titanium alloy (specifically, Ti 735 rolled material) for closing a face opening 12 of the head body 14.

[0058] The top edge 12 of the face opening and the top edge of the face member 16 reach the crown portion of the club head. Accordingly, the top edge 18 of the face member 16 serves as a part of the crown portion of the club head when the face member 16 is bonded to the periphery of the face opening 12 of the head body 14.

[0059] According to this example, the face member 16 has a maximum...

example 2

[0061]FIG. 5 is a perspective view showing another example of the club head according to the invention. The club head of this example is formed into a wood club head having a cavity.

[0062] The club head of this example comprises the head body 34 made of titanium alloy (specifically, a cast material of 6-4 Ti) having the face opening 32 on the face portion 30, and the face member 36 made of titanium alloy (specifically, a rolled material of SP700) for closing the face opening 32.

[0063] The top edge of the face opening 32 and the top edge of the face member 36 reach the crown portion of the club head as in example 1. Accordingly, the upper edge 18 of the face member 36 serves as a part of the crown portion when the face member 36 is bonded to the periphery of the face opening 32.

[0064] The maximum height H of the face member 36 is 54 mm, and the maximum width W of the face member 36 is 75 mm. The W / H ratio is 1.389. The maximum height L of the face portion is 59 mm, and the head vo...

example 3

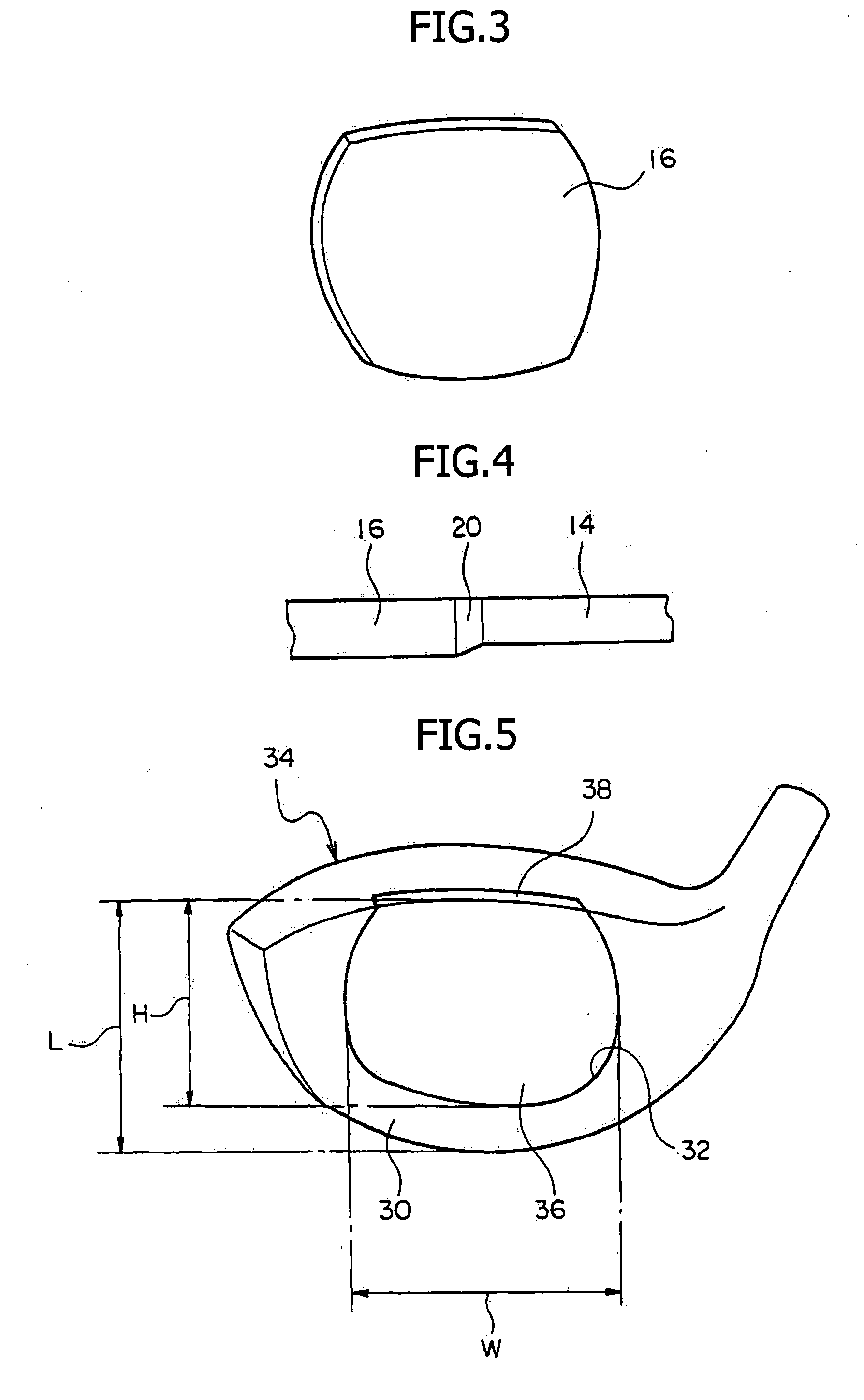

[0070] An example is given for the club head that has differing thicknesses of the face member. On the back side of such a face member an inclined portion is provided as shown in FIG. 9. FIG. 9 shows a club head having a face member that has an inclined portion on the back surface. FIG. 9(a) shows a front view and FIG. 9(b) shows a corresponding cross-sectional view of the face member. The club head comprises a head body 124 having a face opening 122 in the face portion 120, and a face member 126 for closing the face opening 122. A region 128 having the maximum thickness and another region 130 having the maximum thickness are formed on the back surface of the face member 126, and the inclined portion 132 where the thickness continuously changes is provided between the two regions 128 and 130. The region 128 having the maximum thickness contains the centroid of the face portion 120. These regions 128 and 130 may have a circular shape or an ellipsoidal shape which is elongated in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com