Flying saucer structure

a saucer and saucer technology, applied in the field of saucers, can solve the problems of more difficult prediction of landing position and more challenging games, and achieve the effect of more challenging games

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

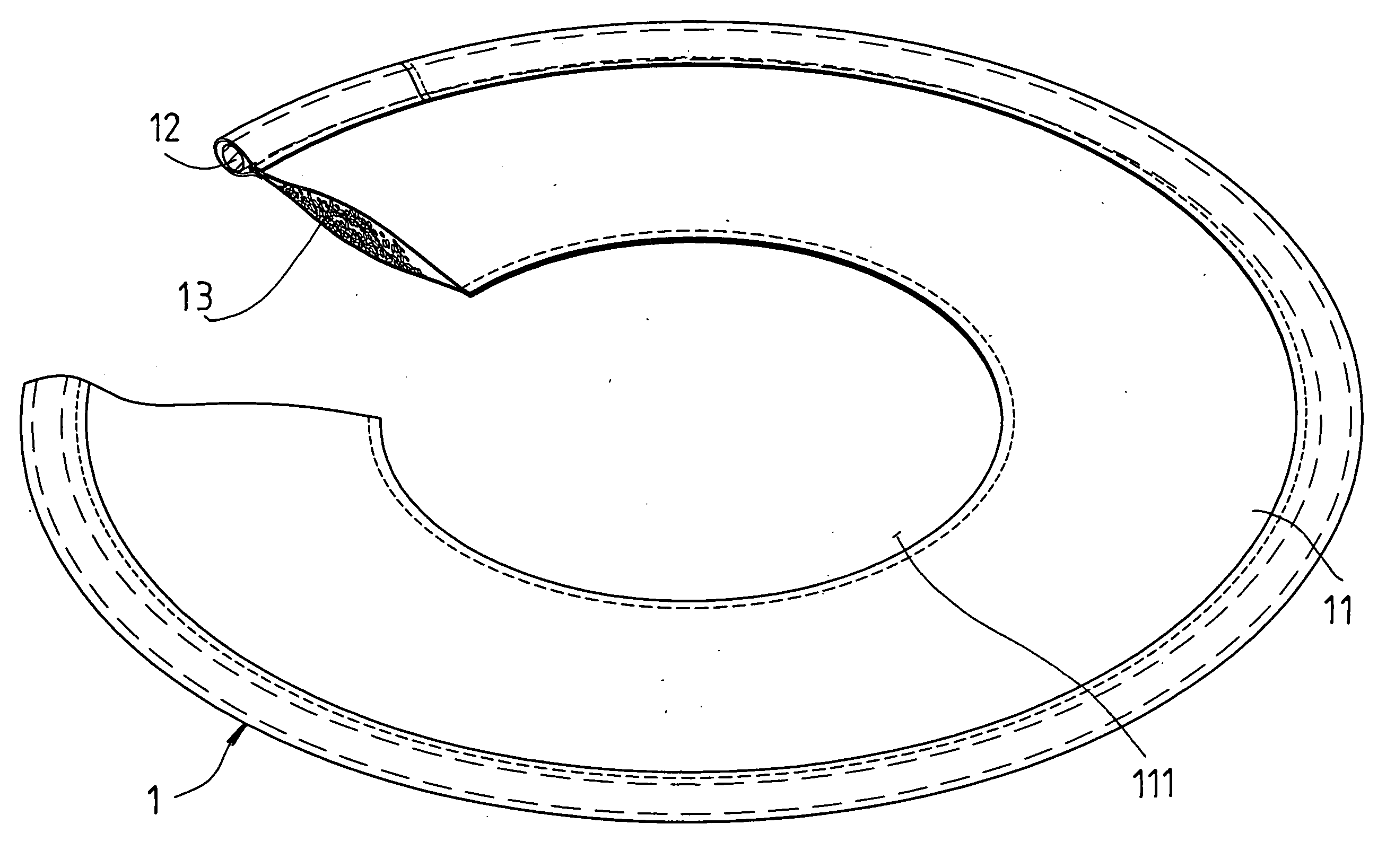

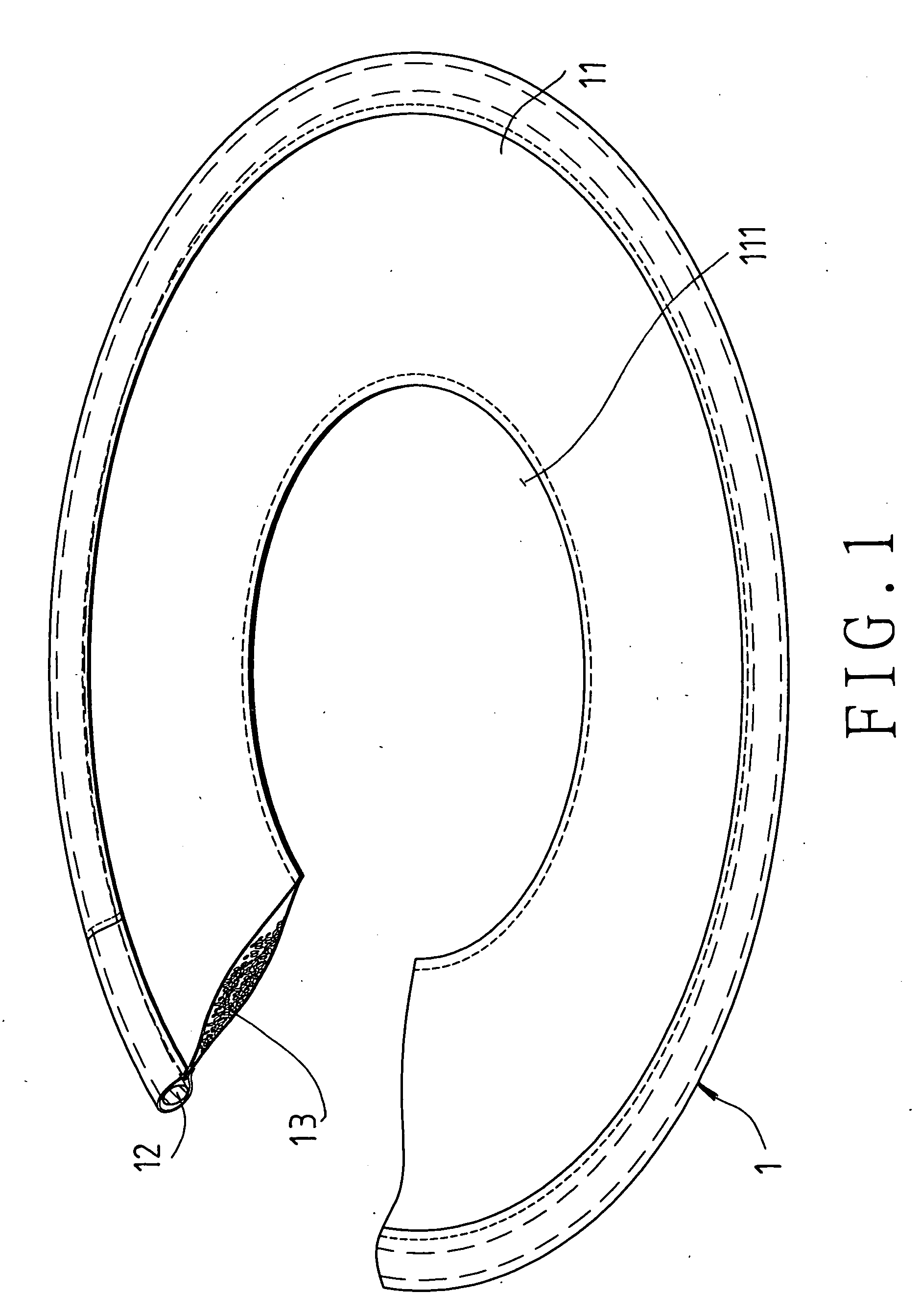

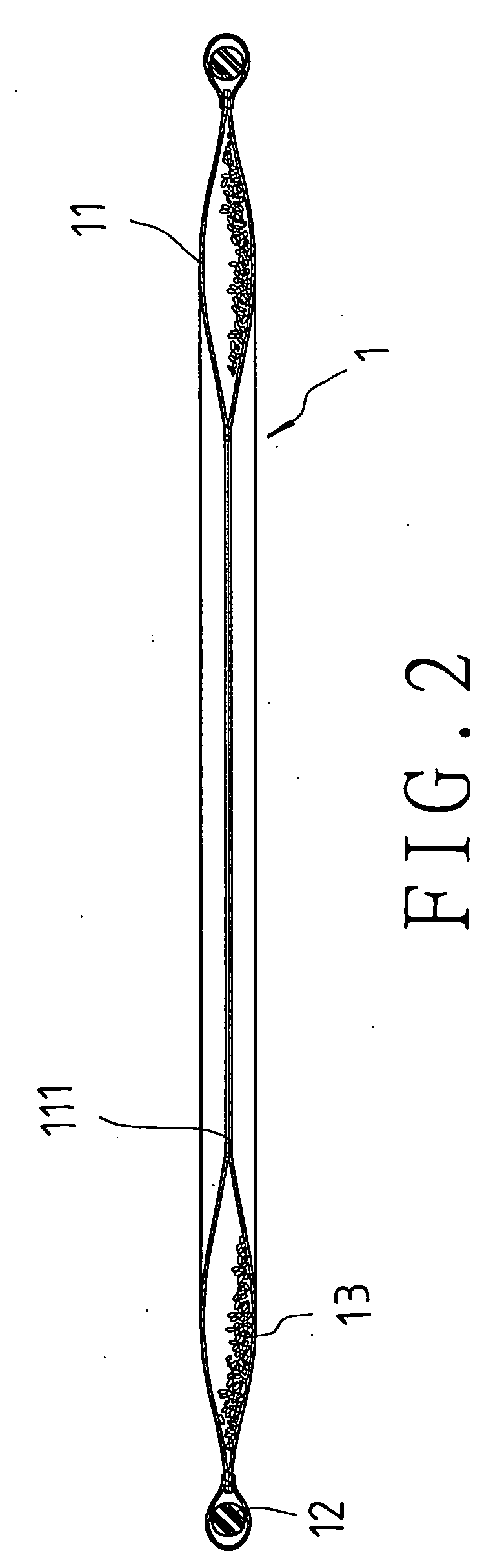

[0014] Referring to FIGS. 1 and 2, a first preferred embodiment of a flying saucer 1 of the invention includes a main body 11, a shape-maintaining ring 12, and many pellet-shaped loads 13.

[0015] The main body 11 is made of soft materials such as non-woven fabrics, and it has a ring shape with a through hole 111 on a middle portion thereof. Furthermore, the main body 11 is hollow, having a holding room therein. The shape-maintaining ring 12 is soft, and it is positioned around and joined to an outward edge of the main body 11 for maintaining the shape of the main body 11. The pellet-shaped loads 13 are held in the holding room of the main body 11.

[0016] To play with the flying saucer 1, referring to FIG. 3, the user should hold the flying saucer 1 with one hand, and move the hand in a curved path to make the flying saucer 1 fly away; the flying saucer 1 will rotate when flying along. And, the pellet-shaped loads 13 will move close to one side of the flying saucer 1 owing to the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com