Trigger mechanism and a firearm containing the same

a technology of trigger mechanism and firearm, which is applied in the direction of firing/trigger mechanism, weapon components, weapons, etc., can solve the problems of affecting the safety of the firearm, the surface and edge edges of the two hardened steel components of the sear can degrade, and the sudden and unexpected discharge of the firearm without warning. , to achieve the effect of reducing friction and crisp feel during discharg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will now be described more fully hereinafter, in which various embodiments of the invention are shown. This invention may, however, be embodied in many different forms and should not be construed as being limited to the embodiment explicitly set forth herein.

1. Firearm

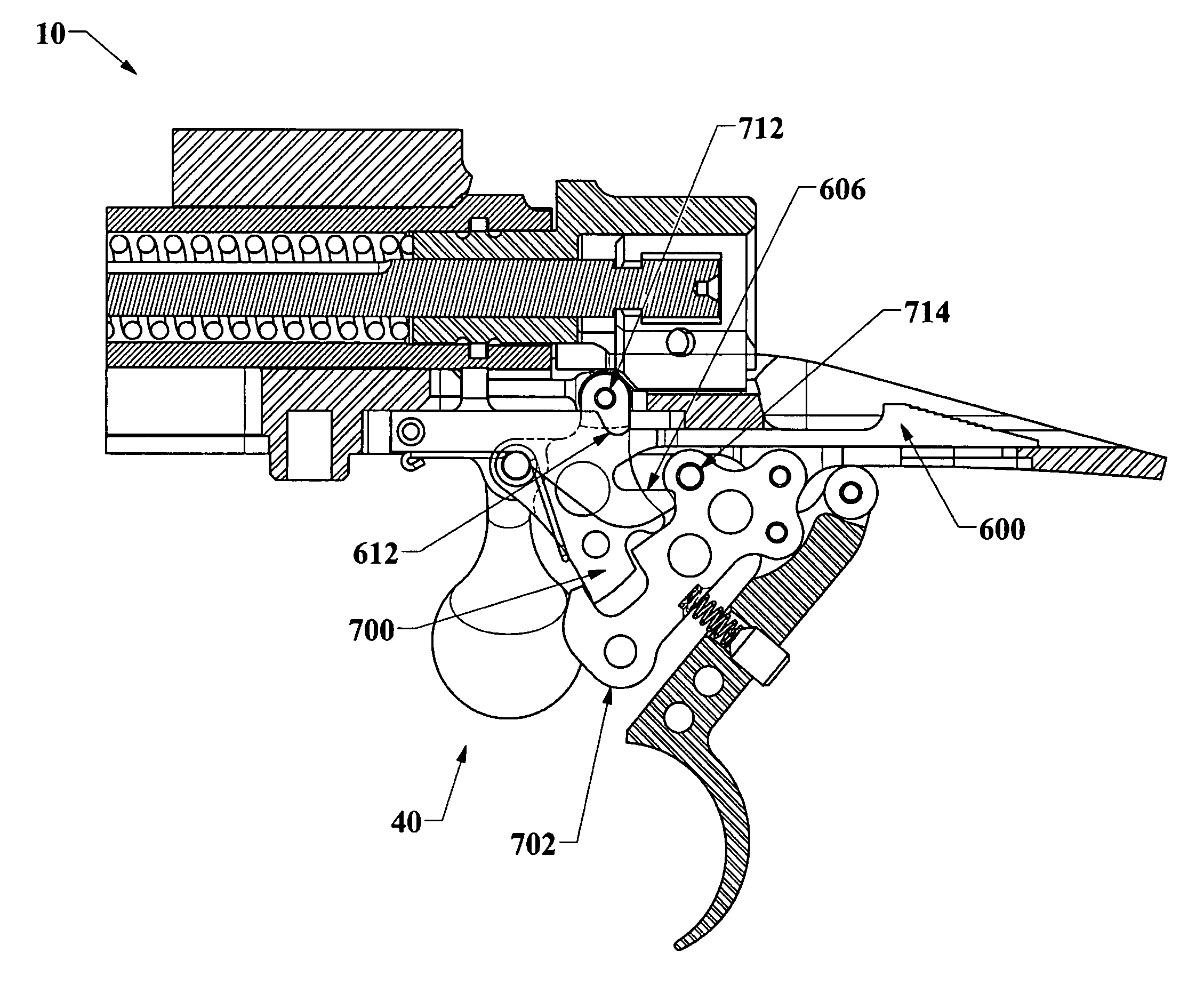

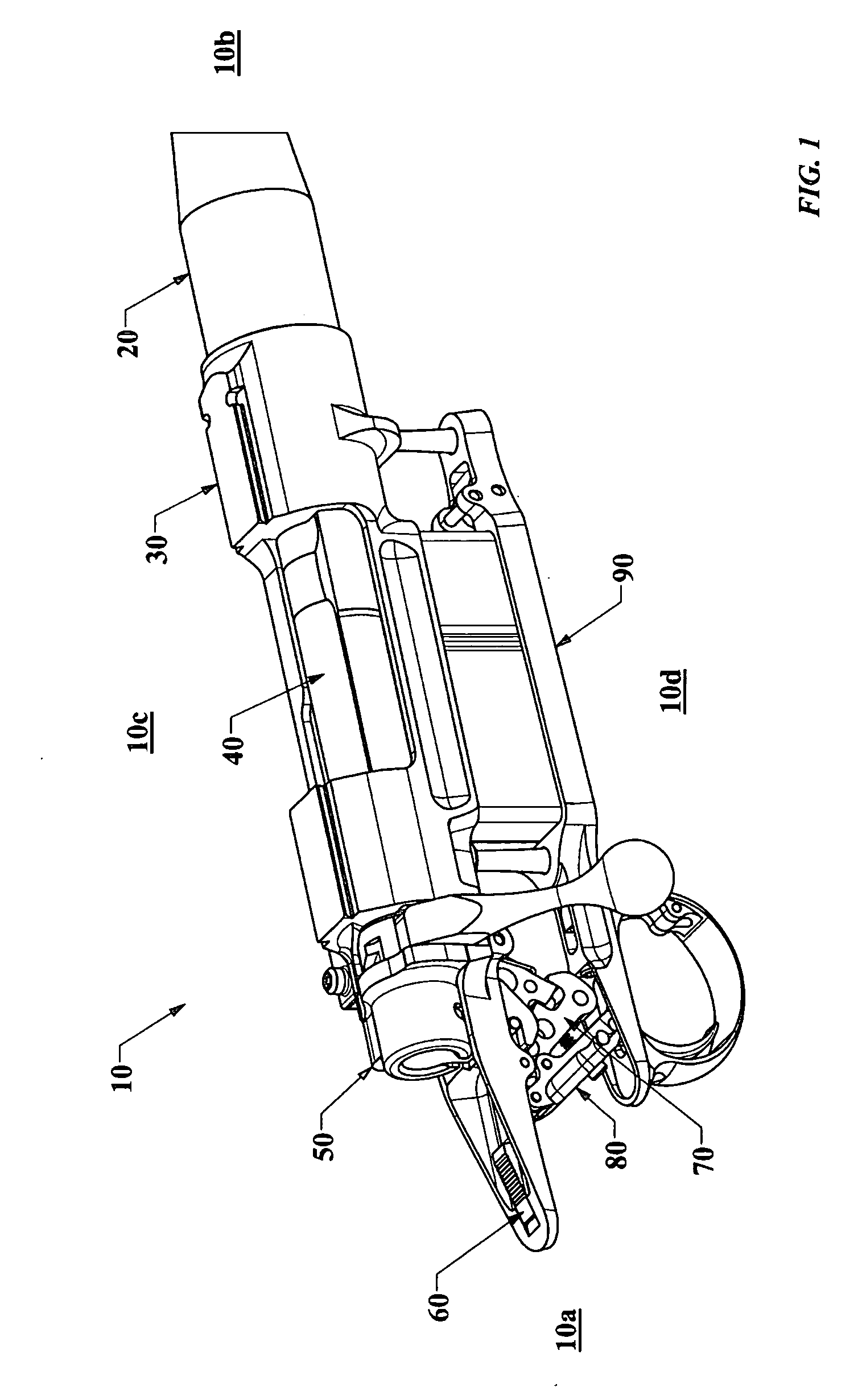

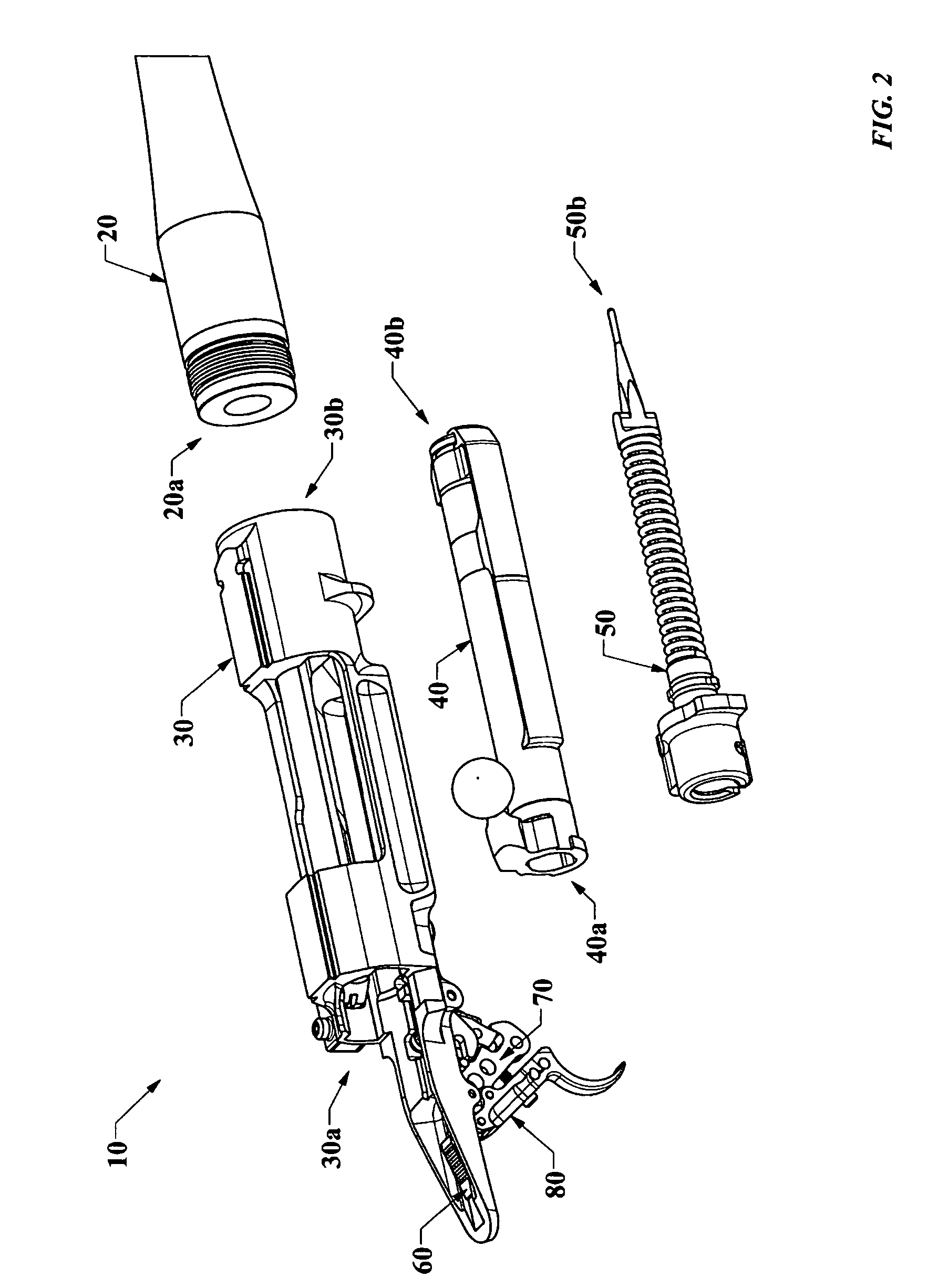

[0061] In accordance with certain embodiments of the present invention, FIG. 1 shows a view of a firearm 10 composed of a barrel 20, a receiver assembly 30, a bolt assembly 40, a firing pin assembly 50, a safety assembly 60, a sear assembly 70, a trigger assembly 80, and a floor plate assembly 90. Barrel 20 is connected to receiver assembly 30. Receiver assembly 30 is connected to bolt assembly 40, firing pin assembly 50, safety assembly 60, sear assembly 70, trigger assembly 80, and floor plate assembly 90. Trigger assembly 80 is connected to sear assembly 70.

[0062] As indicated in FIG. 1, a proximal end 10a of firearm 10 refers a region near trigger assembly 80, and the distal end 10b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com