Container With Peelable Seal Assembly and Method of Making

a technology of peelable adhesive and packaging, applied in the field of containers, can solve the problems of difficult to consistently create bags with the same low opening effort, the peelable adhesive thickness has an influence on the effort required to break the seal, and the bag seal is difficult to break, so as to eliminate the variation in the effort to open various bags. , the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

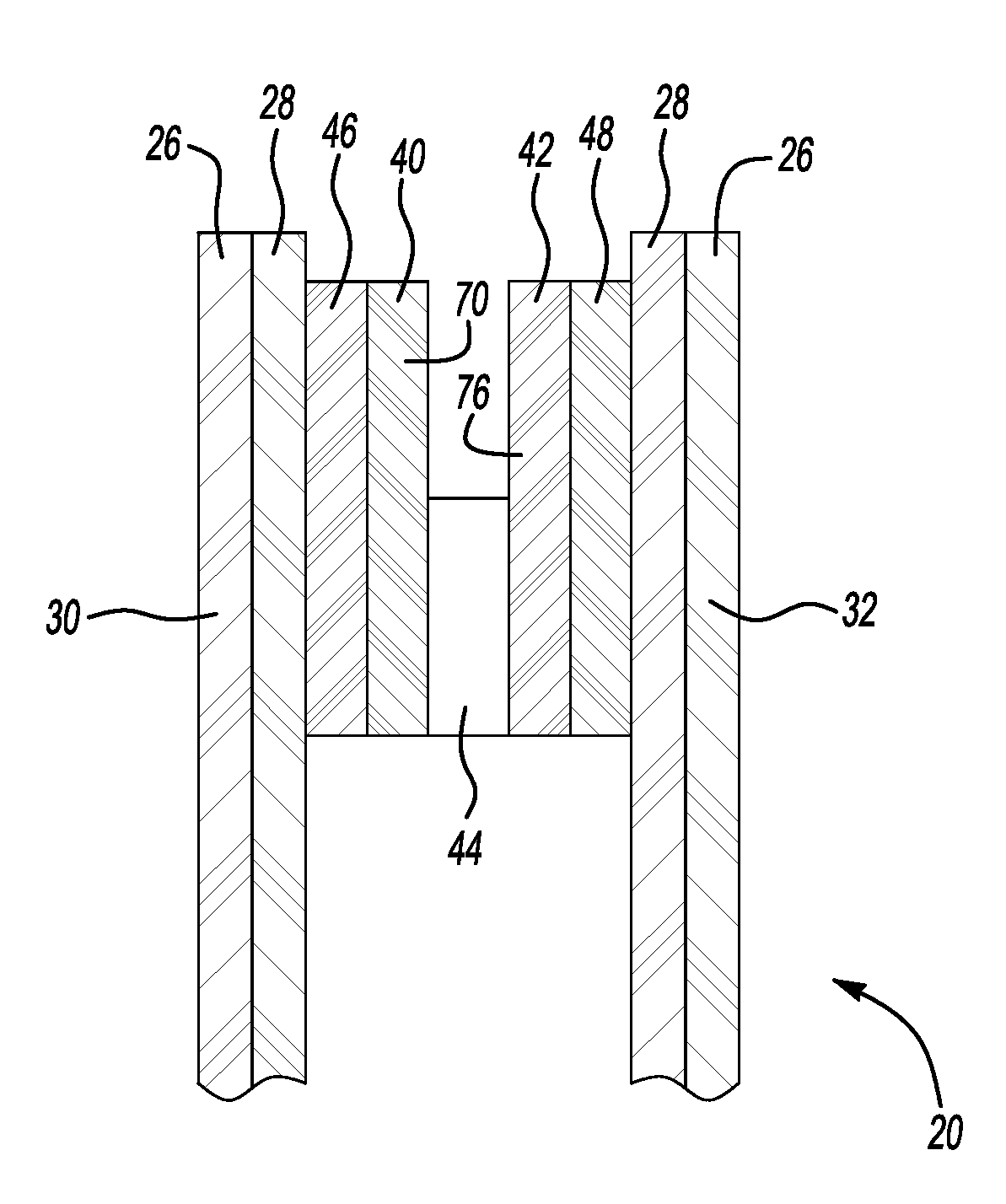

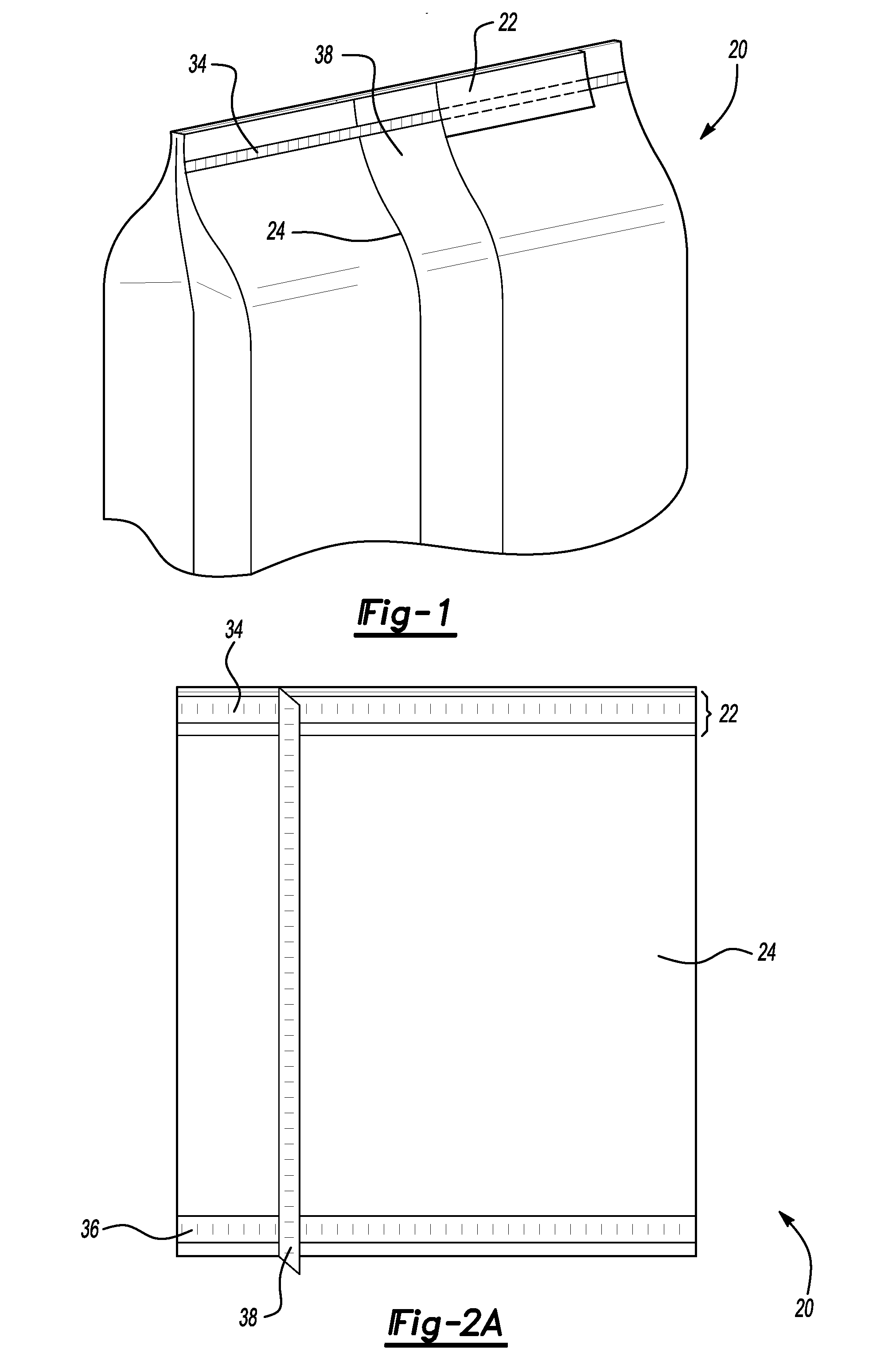

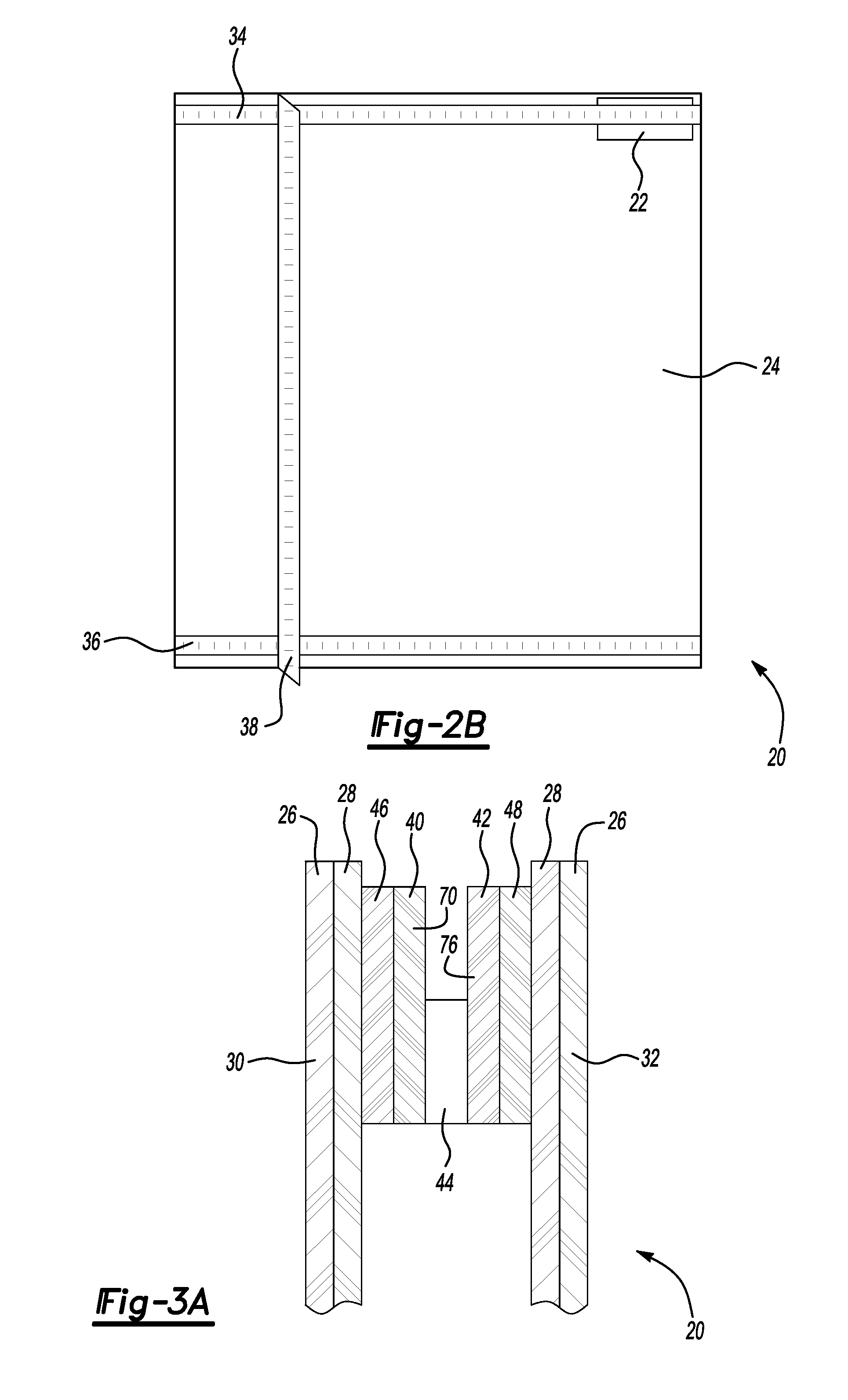

[0020] Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a flexible bag 20 with a peelable seal assembly 22 is shown.

[0021] The bag 20 is formed from a liner 24 which includes a first layer 26 and a second layer 28 coextruded with the first layer 26 (See FIGS. 1 and 3a). The first layer 26 is preferably high density polyethylene. The second layer 28 is a peelable adhesive, and is more preferably low density polyethylene with polybutylene. It will be understood by those of ordinary skill in the art that a peelable adhesive is an adhesive that has less adhesive strength allowing it to be peeled apart or opened. An example of a peelable adhesive is the use of an adhesive layer that has an additive mixed into the adhesive layer to lower the adhesive strength. Those of ordinary skill in the art commonly refer to this additive as a contaminant. The liner 24 is folded to define a first side 30 and a second side 32 such that the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat resistant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com