Superconducting magnet system with refrigerator for re-liquifying cryogenic fluid in a tubular conduit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

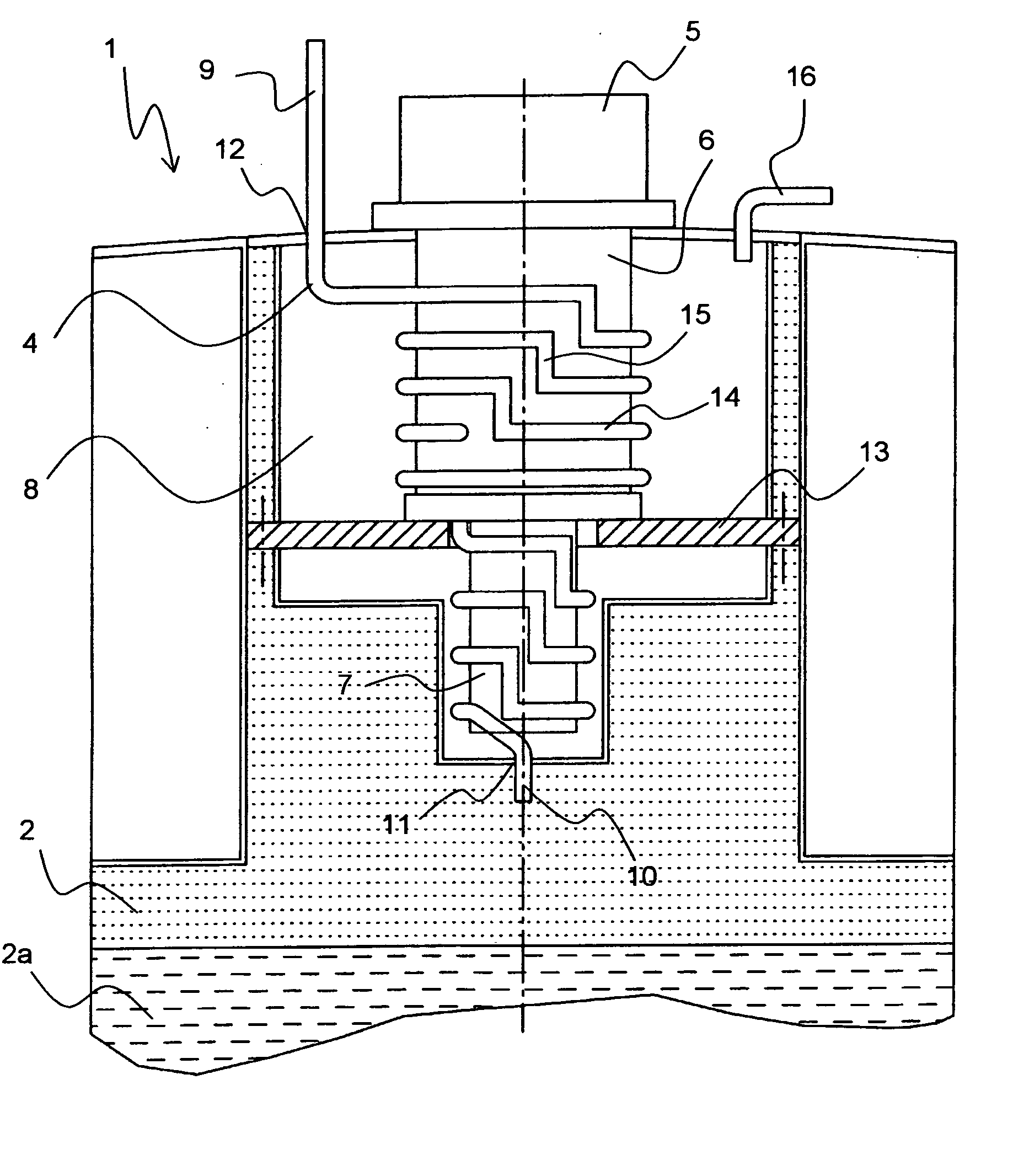

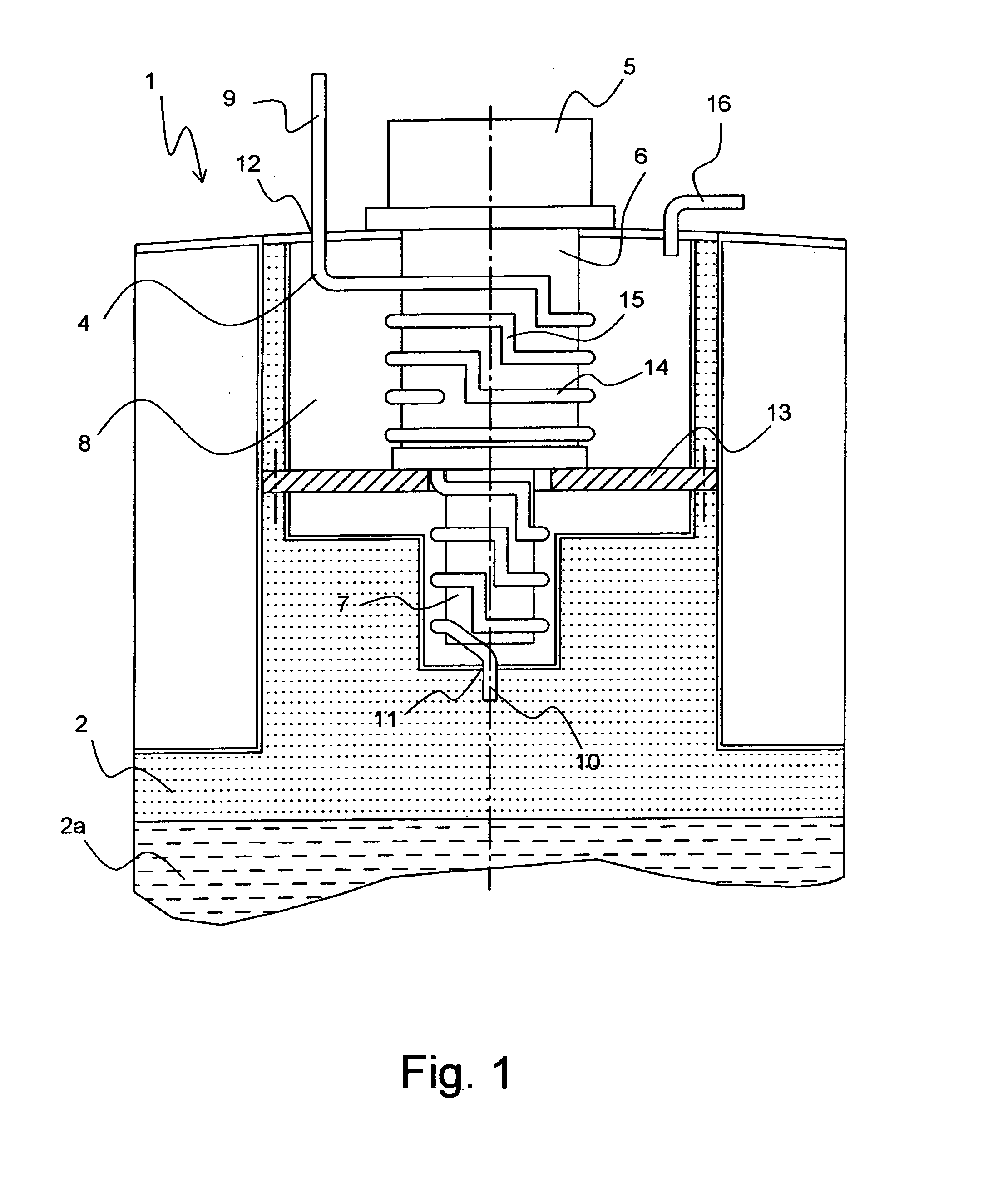

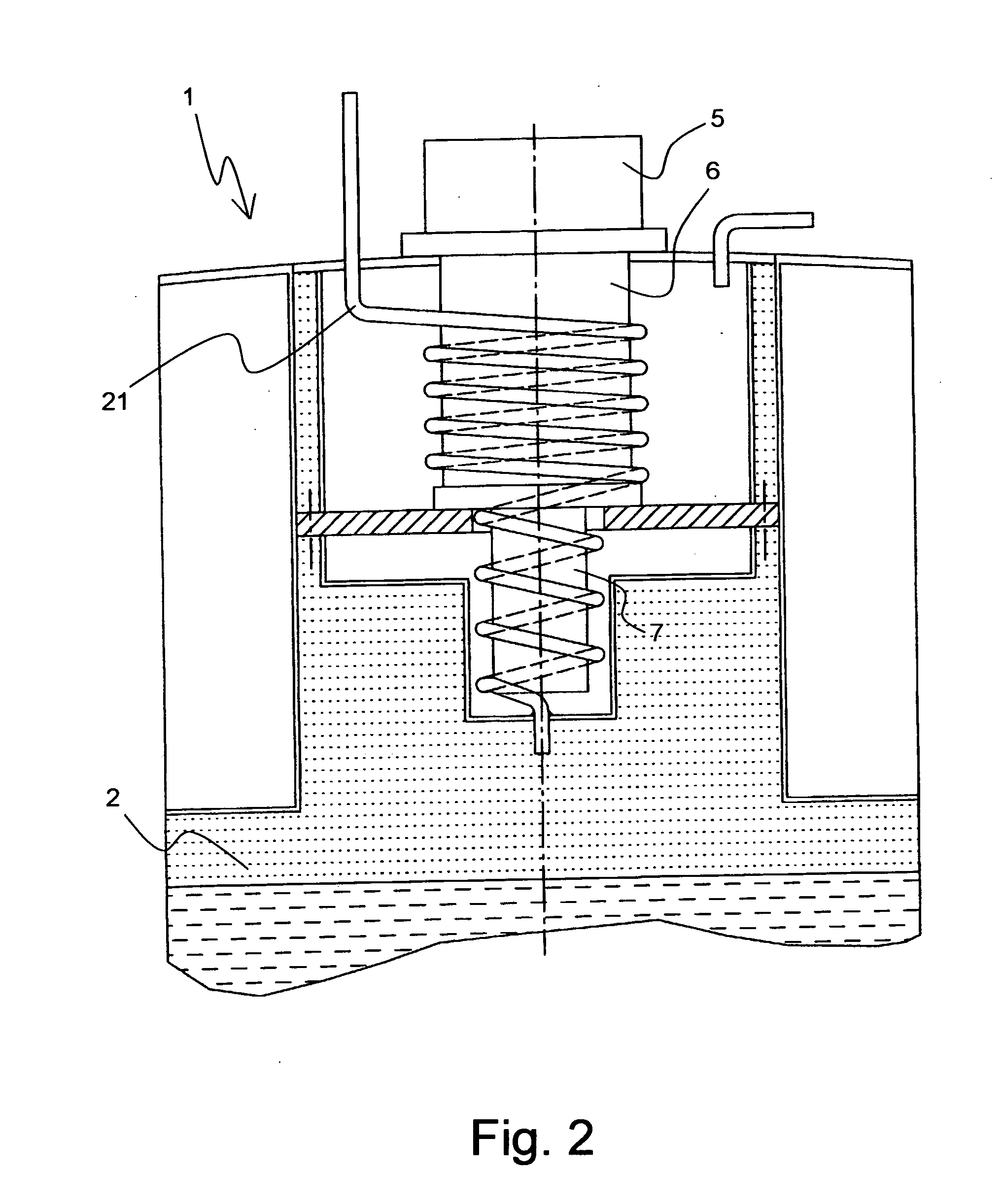

[0035]FIG. 1 schematically shows part of an inventive superconducting magnet system, i.e. the neck tube region of a cryostat 1. The cryostat 1 has a cryogenic fluid tank 2 whose lower region contains liquid cryogenic fluid 2a, i.e. helium. A superconducting magnet coil configuration (also not shown) is located in the region of the liquid cryogenic fluid 2a. Gaseous cryogenic fluid (indicated by dots in FIG. 1) is located above the liquid cryogenic fluid 2a. Cryogenic fluid is permanently pumped to reduce the temperature. The pumped cryogenic fluid is thereby heated outside of the cryogenic fluid tank 2.

[0036] The heated, gaseous cryogenic fluid is cooled and returned, in its liquified state, to the cryogenic fluid tank 2 via a tubular conduit 4. A refrigerator 5 cools the cryogenic fluid. The refrigerator 5 has a first cooling stage 6 and a second, colder cooling stage 7. These two cooling stages 6, 7 are contained in a vacuum container 8 to thermally insulate them from the surroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com