Washing machine

a technology of washing machine and receptacle, which is applied in the direction of washing machine with receptacle, other washing machines, textiles and paper, etc., can solve the problems of increasing the generation frequency of failures, increasing the number of potential failure areas, and complicated product assembly operation, so as to reduce noise and failure generation, and without the risk of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0062] Now, the present invention will be described in detail with reference to FIGS. 2 to 7.

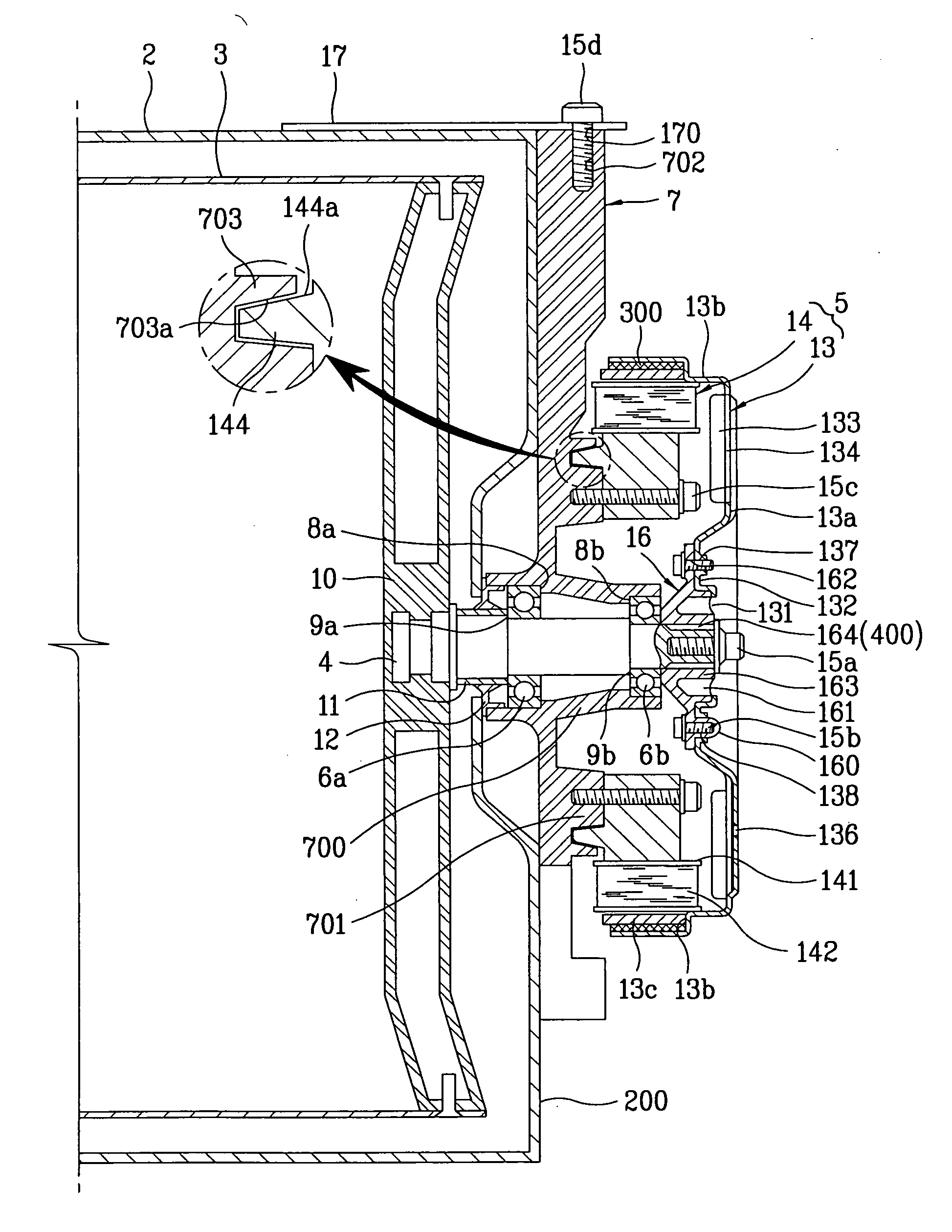

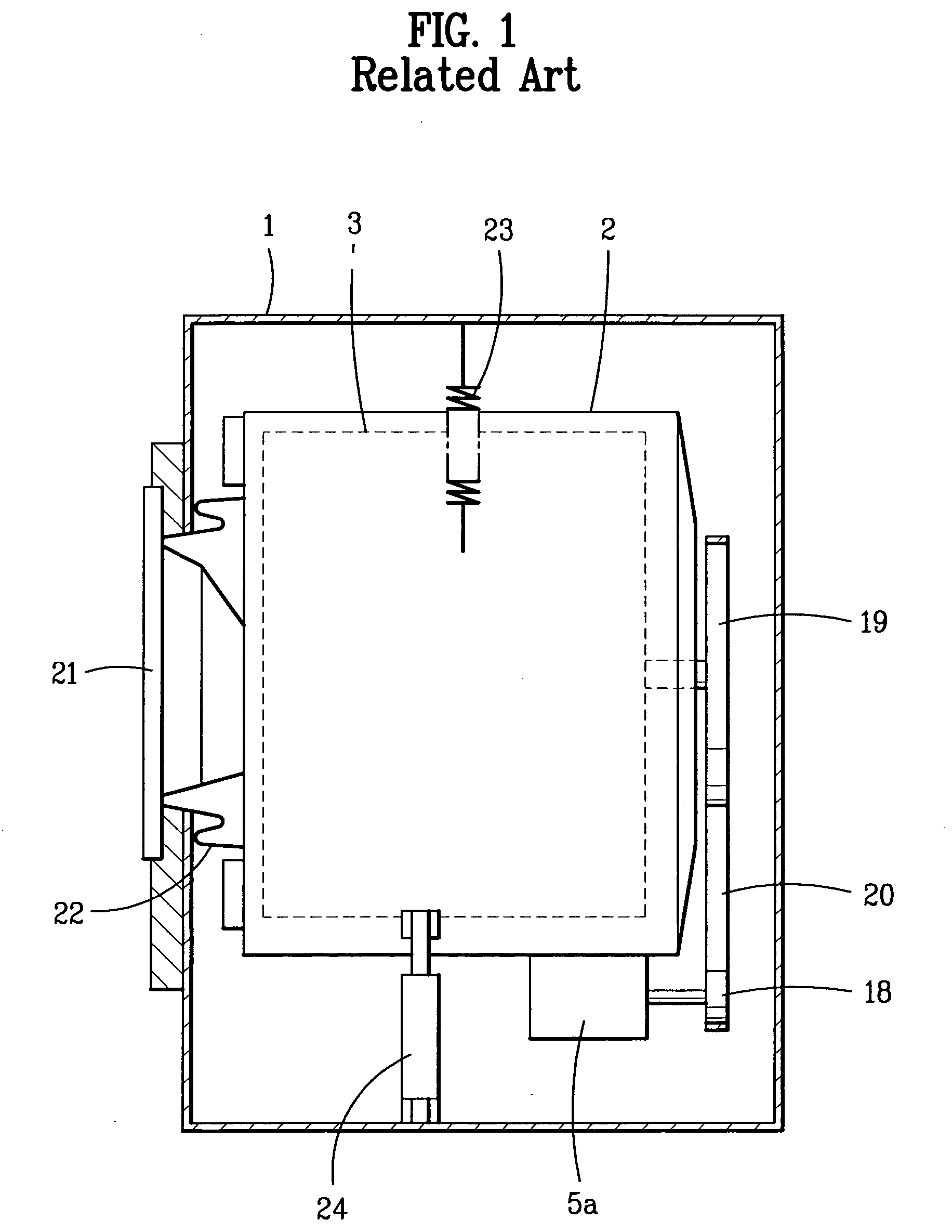

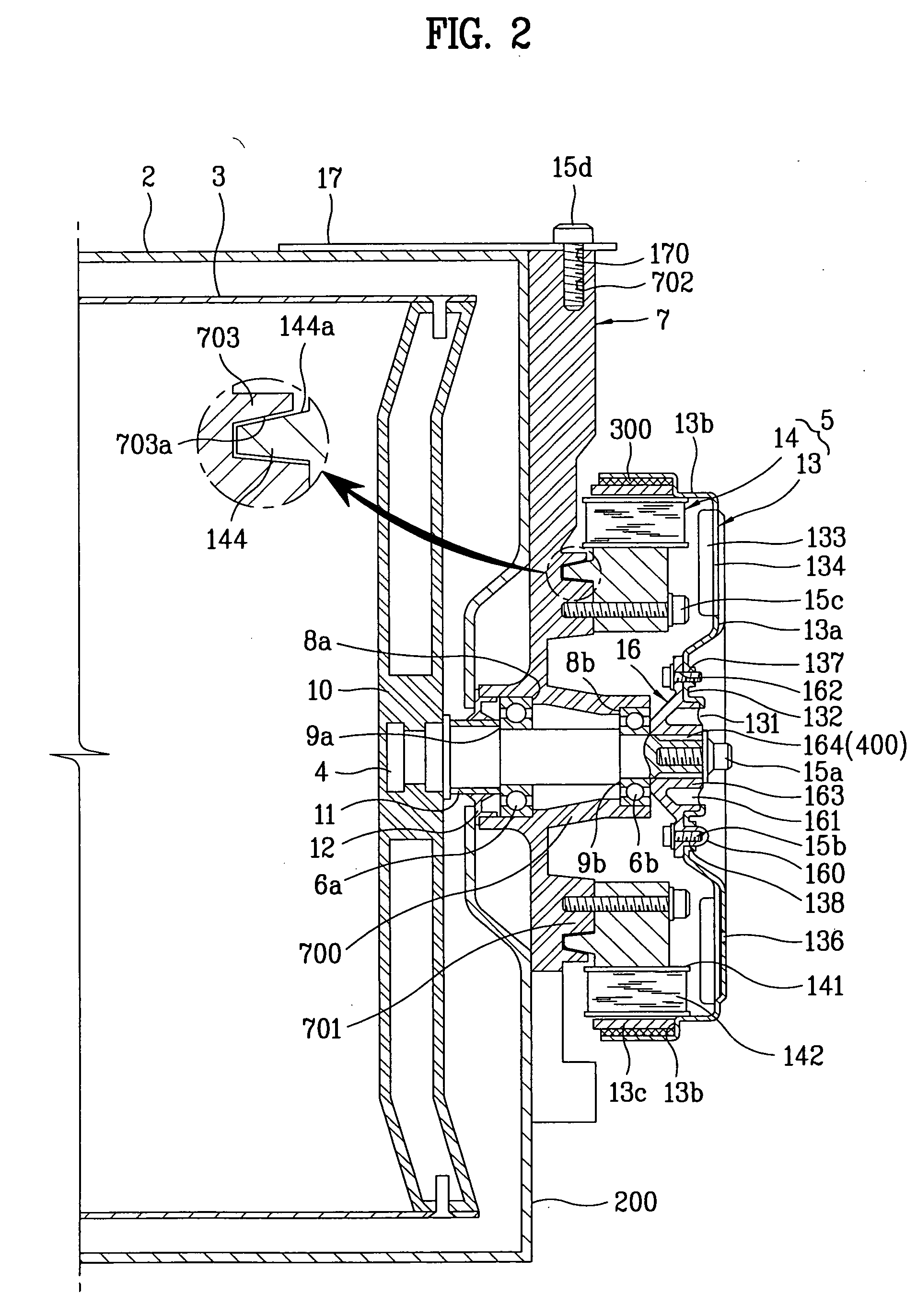

[0063]FIG. 2 is a longitudinal sectional view illustrating important parts of a drum type washing machine according to a first embodiment of the present invention, and FIG. 3 is a right side view of FIG. 2, in which the illustration of a motor is omitted.

[0064]FIG. 4 is a partially cut-away perspective view illustrating a rotor shown in FIG. 2, FIG. 5 is a perspective view illustrating a stator shown in FIG. 2, FIG. 6 is a perspective view illustrating a connector shown in FIG. 2, and FIG. 7 is a bottom perspective view of FIG. 6.

[0065] The drum type washing machine according to the present embodiment comprises a tub 2 installed in a cabinet (not shown) and used to receive wash water therein, a drum 3 rotatably provided in the tub 2 and adapted to wash laundry received therein as it is rotated, a shaft 4 penetrated through the tub 2 and connected to the drum 3, the shaft 4 being adapted to...

second embodiment

[0120]FIG. 8 is a longitudinal sectional view schematically illustrating the configuration of a drum type washing machine using a direct connection motor according to the present embodiment, and FIG. 9 is an enlarged longitudinal sectional view of the portion “A” of FIG. 8, illustrating the configuration of a drive unit included in the drum type washing machine according to the present invention.

[0121]FIG. 10 is a perspective view illustrating the rear wall portion of the tub shown in FIG. 9, FIG. 11 is a top perspective view of the bearing housing shown in FIG. 9, FIG. 12 is a rear perspective view of the bearing housing, and FIG. 13 is a sectional view taken along the line I-I of FIG. 11.

[0122] The present embodiment has a feature in that a bearing housing 7′ is integrally formed with the tub 2, which is made of a plastic material, at the center of the rear wall portion of the tub 2. The bearing housing 7′ of the present embodiment can rotatably support the shaft 4 while allowing...

fourth embodiment

[0147] Now, a drum type washing machine according to the present invention will be described in detail with reference to FIG. 15.

[0148] The present embodiment has a feature in that a distance regulation washer is provided in addition to the configuration of the above described fourth embodiment. The distance regulation washer is interposed between the supporter and the stator and adapted to regulate a distance between the tub and the stator.

[0149] More specifically, in the present embodiment, the distance regulation washer 500 may be interposed between the supporter 27 and the stator 14 coupled to the supporter 27 and adapted to regulate a distance between the tub 2 and the stator 14. Preferably, the distance regulation washer 500 has an annular form suitable to stably separate the stator 14 from the tub 2. The distance regulation washer 500 may be formed, in a circumferential direction thereof, with a plurality of coupling holes. Accordingly, the distance regulation washer 500 per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com