Strake systems and methods

a technology of strakes and systems, applied in the direction of fluid dynamics, mechanical equipment, pipe laying and repair, etc., can solve the problems of large transverse current vibration, unacceptably short fatigue life, and substantial vibration of structural elements, and achieve the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

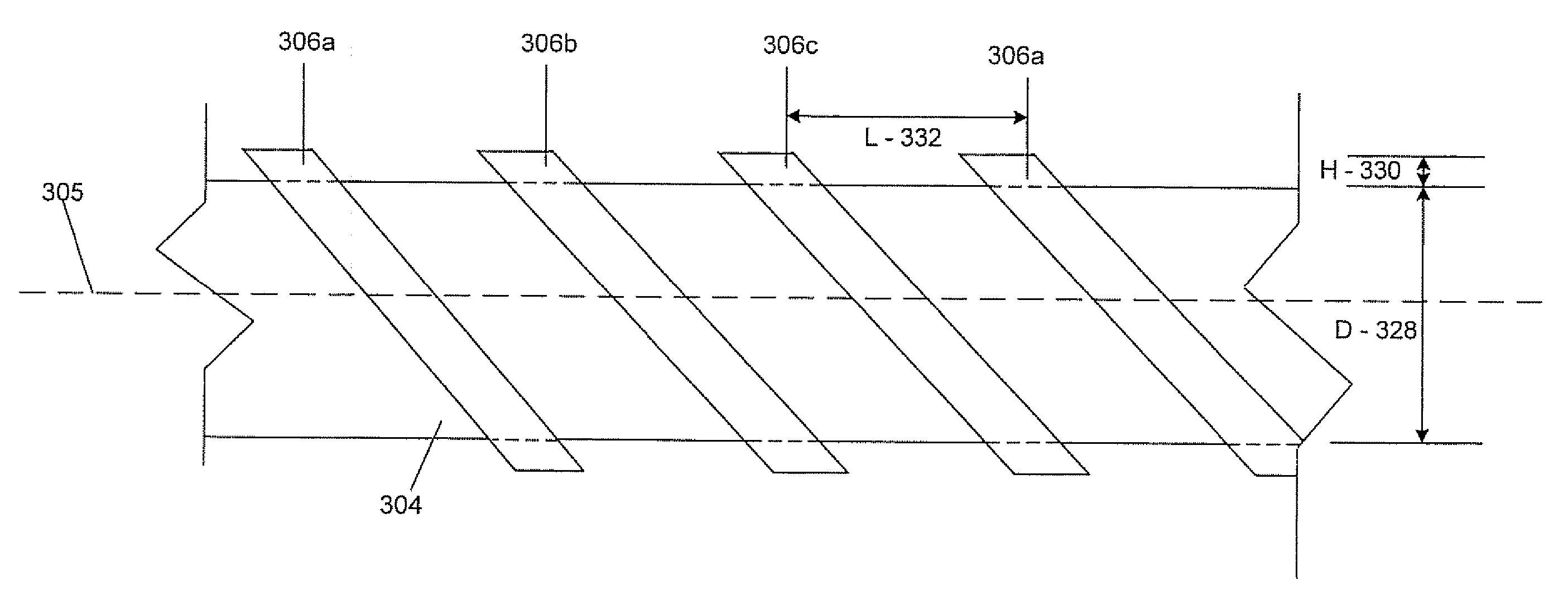

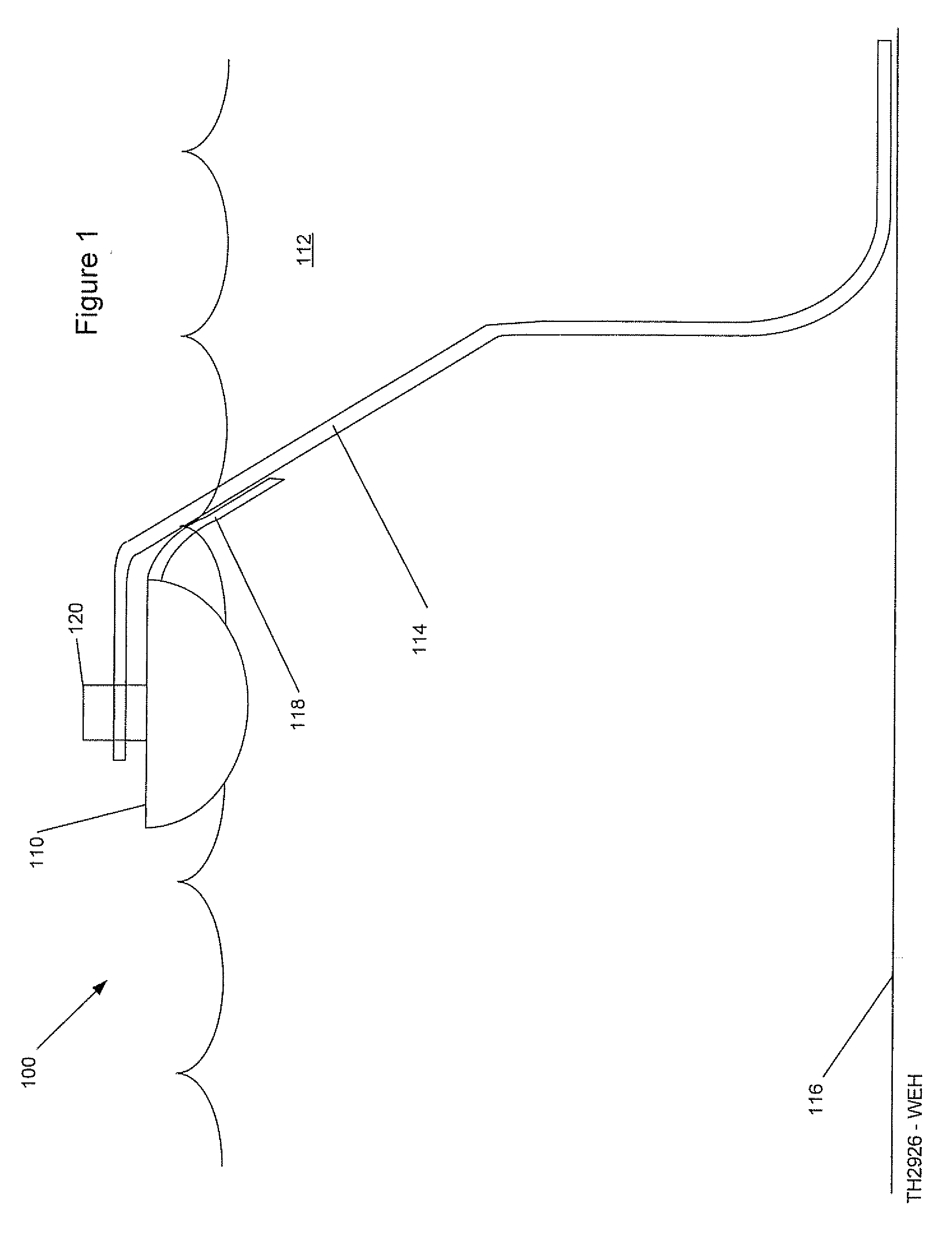

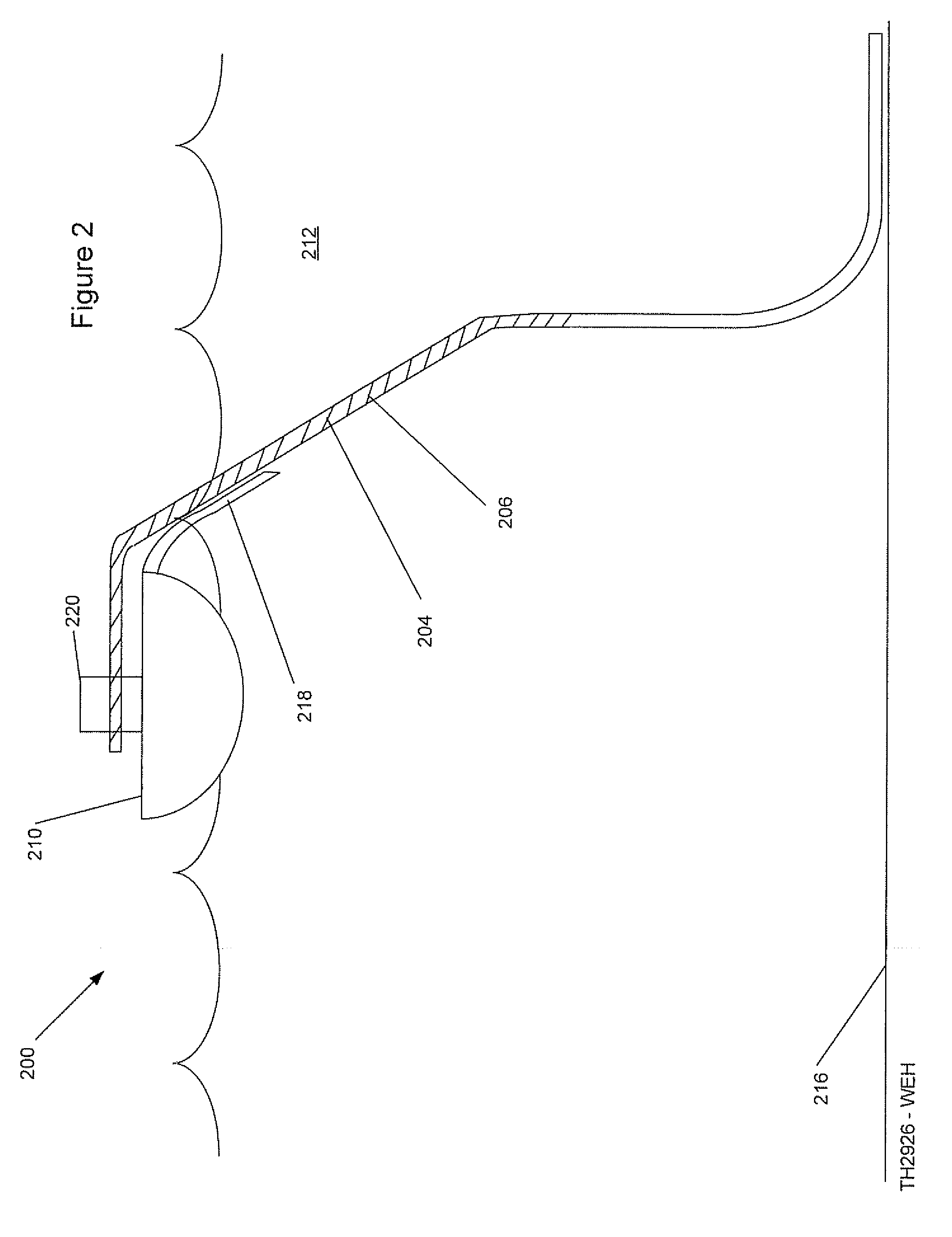

[0027] In one embodiment, there is disclosed a system comprising a structural element, at least one helical strake about the structural element, and at least one ramp to provide a transition from the structural element to the helical strake. In some embodiments, the structural element is selected from the group consisting of a shell, a collar, an oil flowline, a pipeline, a drilling riser, a production riser, a steel tubular, import and export risers, subsea pipelines, tendons for tension leg platforms, legs for traditional fixed and for compliant platforms, space-frame members for platforms, cables, umbilicals, mooring elements for deepwater platforms, hull structures for tension leg platforms and for spar type structures, and column structures for tension leg platforms and for spar type structures. In some embodiments, the structural element comprises a plurality of sections welded to each other. In some embodiments, the structural element comprises a plurality of sections threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com